A tipping tire clamp

A technology of tires and fixing seats, which is applied to storage devices, conveyor objects, transportation and packaging, etc., can solve the problems of complex structure, low work efficiency, and small self-weight, and achieve reduced complexity, safe clamping, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

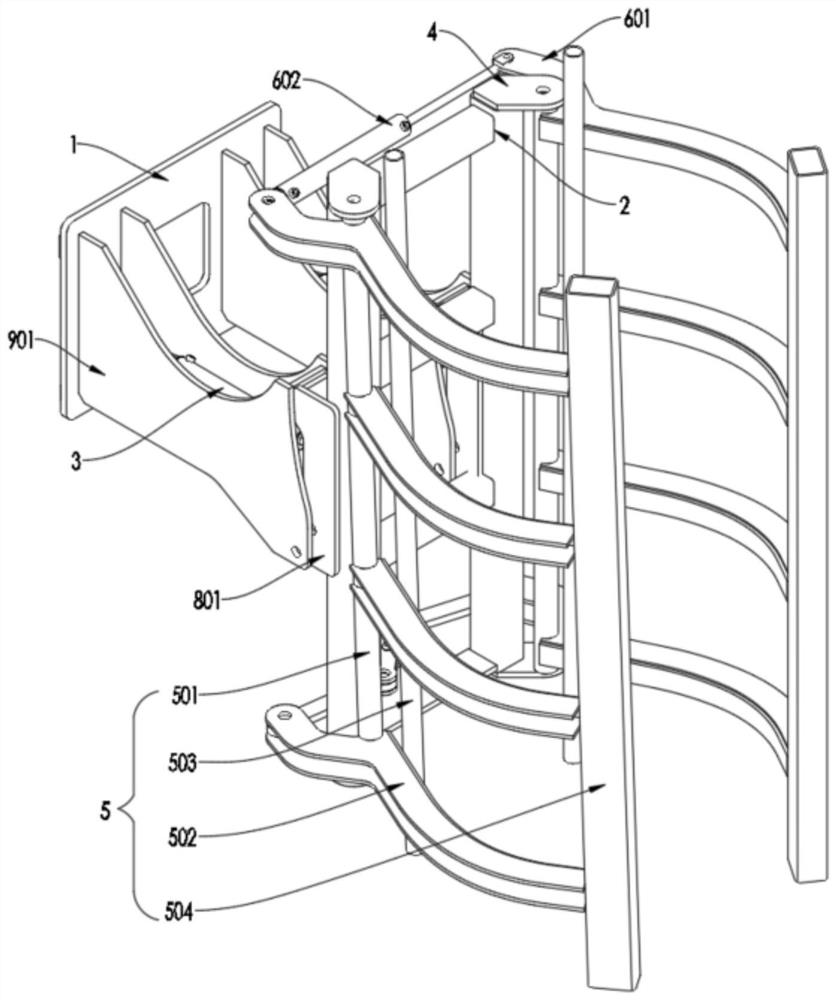

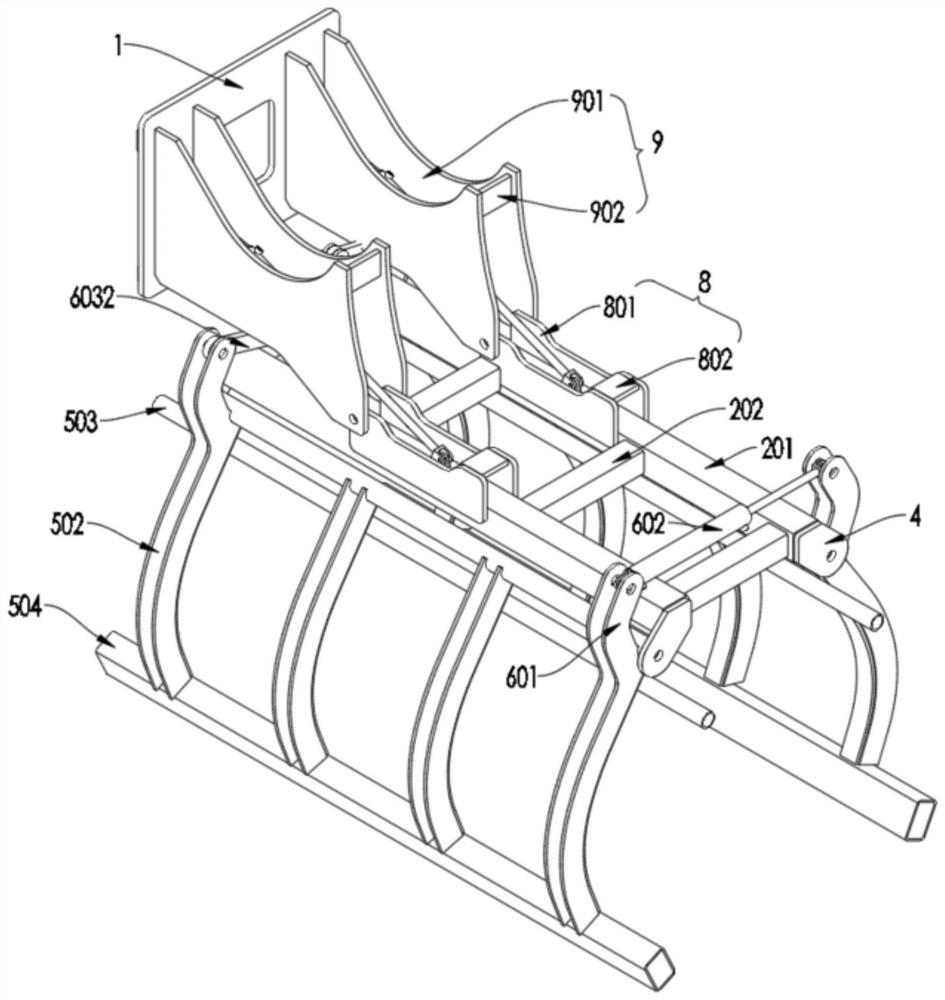

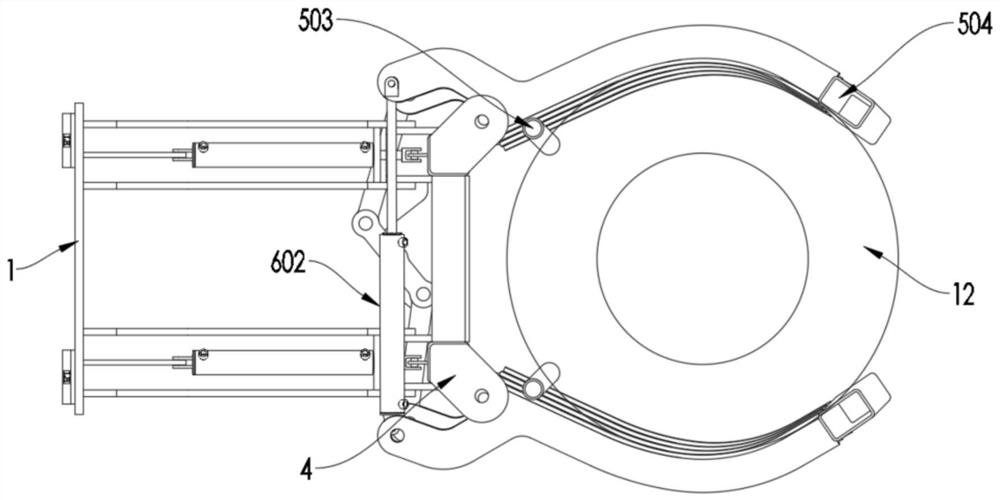

[0037] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with reference to the accompanying drawings:

[0038] refer to Figure 1-6 , a tipping tire clamp comprising

[0039] Fixed seat 1;

[0040] The mounting frame 2 is swingably mounted on the fixing base 1 , a corresponding swing driving hydraulic cylinder 3 is telescopically connected between the mounting frame 2 and the fixing base 1 , and two sides of the upper and lower ends of the mounting frame 2 are respectively fixed with Corresponding fixed mounts 4;

[0041] The clamping arm mechanism 5 includes a set of fixed shafts 501 that are rotatably installed between the fixed mounting members 4 on both sides of the mounting frame 2, and the fixed shafts 501 are respectively fixed to the outside with a plurality of arc-shaped spaced apart. Rod 502, the outer ends of the arc-shaped rods 502 are respectively fixed with correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com