Self-propelled lifting device for battery replacement of electric vehicle

A technology for electric vehicles and lifting devices, applied in electric vehicles, lifting devices, lifting frames, etc., can solve the problems of difficult disassembly and transfer, inflexible use, inconvenient operation, etc., to achieve convenient high-density layout, improve work efficiency, and use Flexible and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Combining Figure 1~Figure 9 The specific implementation of this self-propelled vehicle lifting device provided by the present invention is illustrated as follows:

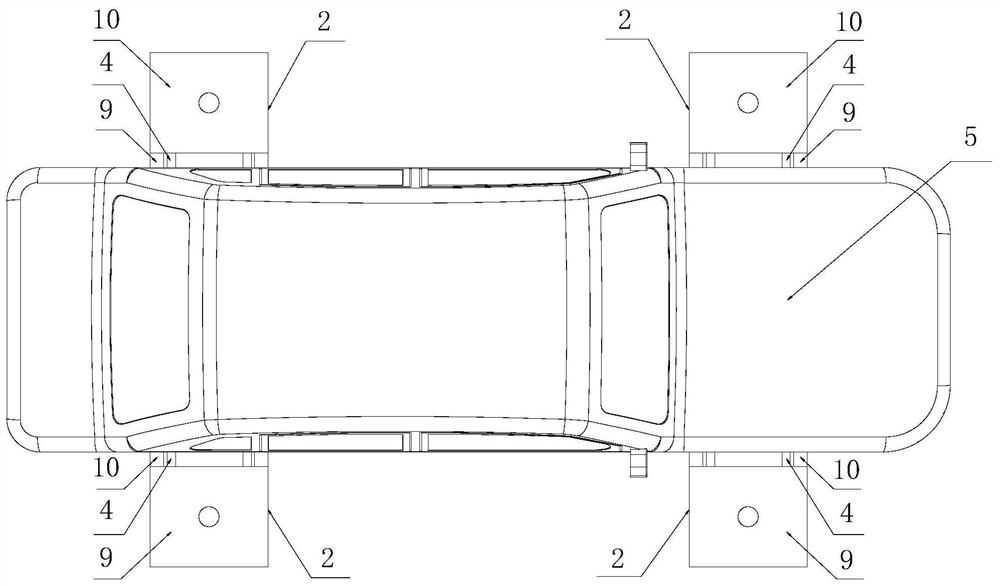

[0043] This self-propelled vehicle lifting device provided by the present embodiment is made up of a self-propelled lifting unit device for synchronously lifting the four wheels 6 of the electric vehicle 5, as figure 1 shown.

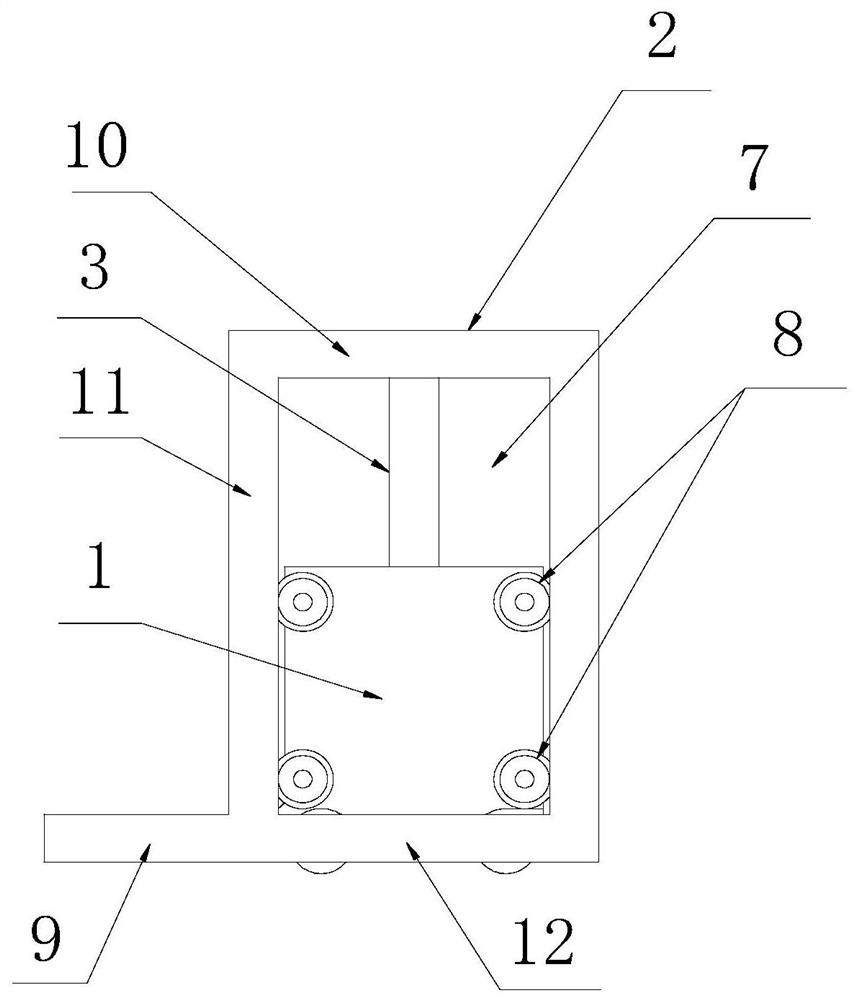

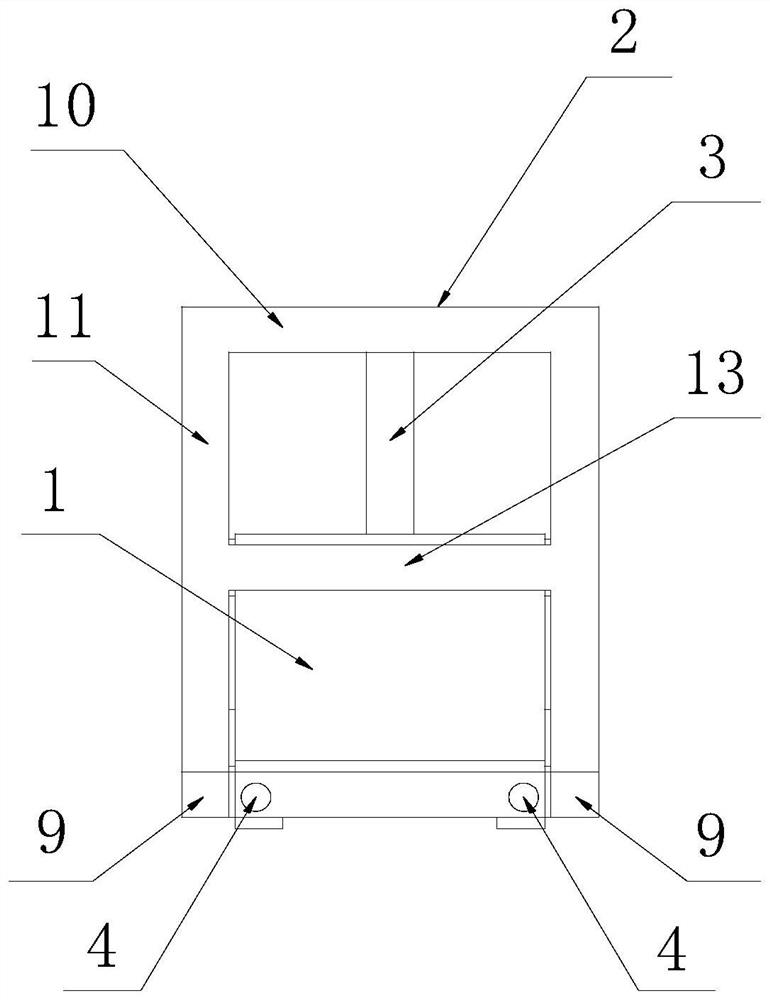

[0044] recombine Figure 2~Figure 4 As shown, each self-propelled lifting unit device is composed of an AGV trolley 1 as a traveling mechanism, a support frame 2 and a lifting drive device 3 . The front part of the AGV trolley 1 is fixed with two fork rods 4 for forking the wheels 6, and in this embodiment, the two fork rods 4 are arranged parallel and horizontally.

[0045] In this embodiment, the support frame 2 is a rectangular parallelepiped frame whose main body is composed of a top plate 10 , four vertical poles 11 fixed on the bottom of the top plate 10 distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com