Peanut shelling roller with variable-diameter flexible beating plates

A shelling drum, flexible technology, applied in threshing equipment, seed and rhizome treatment, agricultural machinery and implements, etc. Problems such as poor variety adaptability, to achieve the effect of improving the quality of shelling operations, facilitating replacement, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

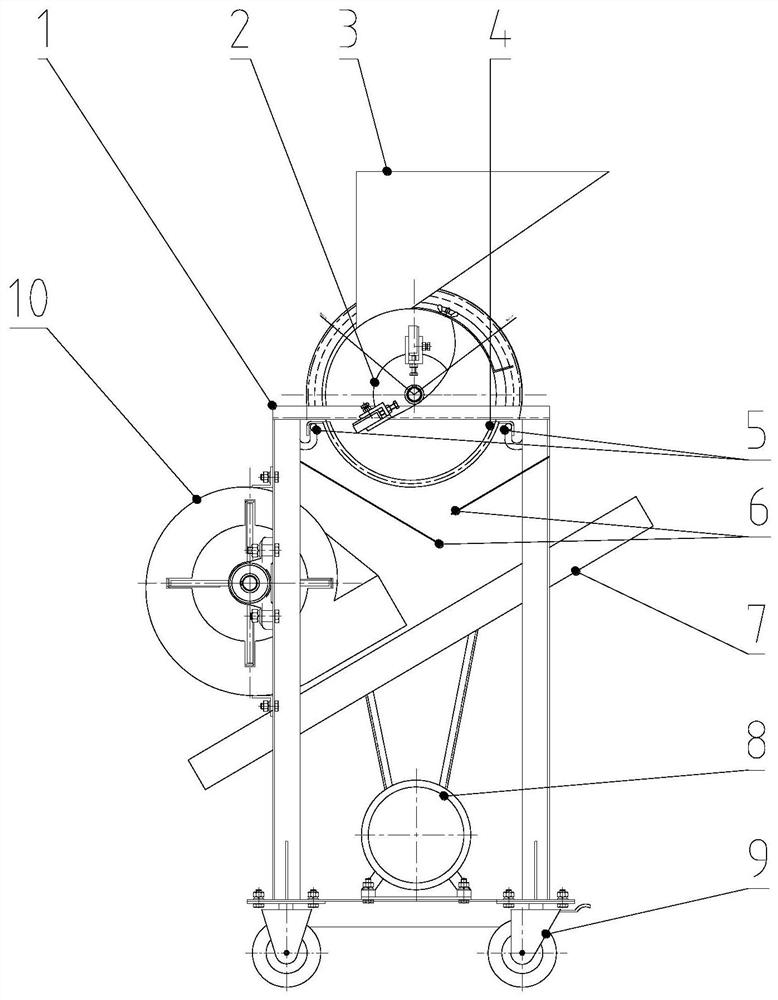

[0024] see figure 1 , Small breeding shelling machine, including shelling drum 2, concave screen 4, feeding device 3, U-shaped guide rail 5, guide rod 11.

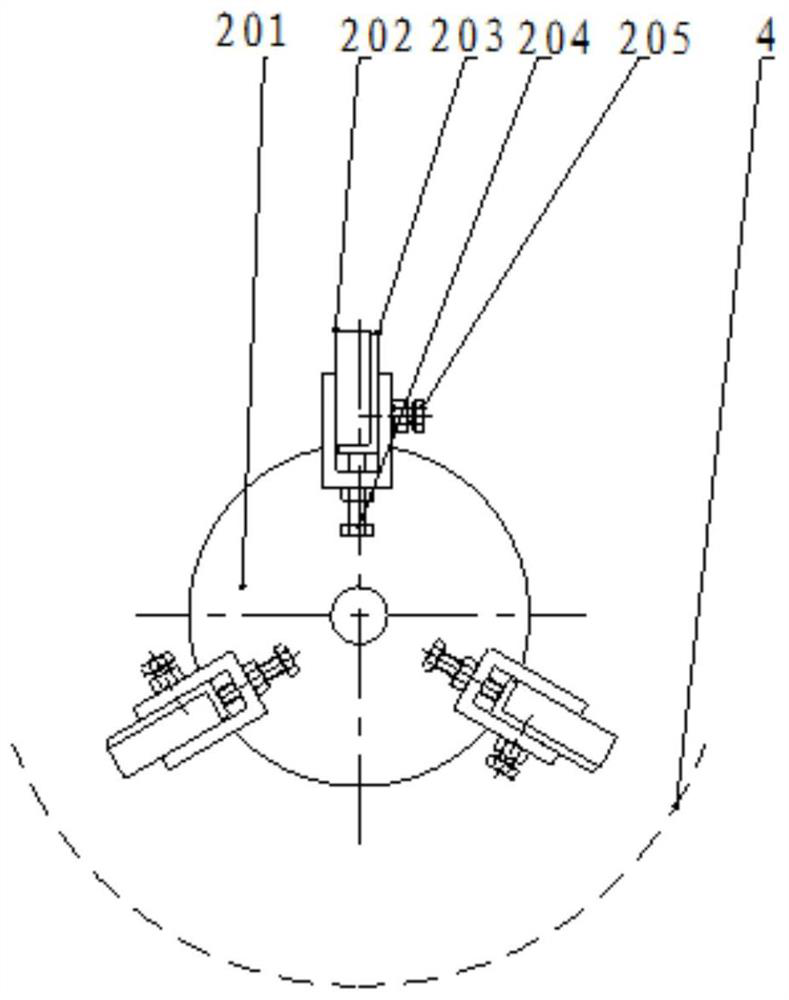

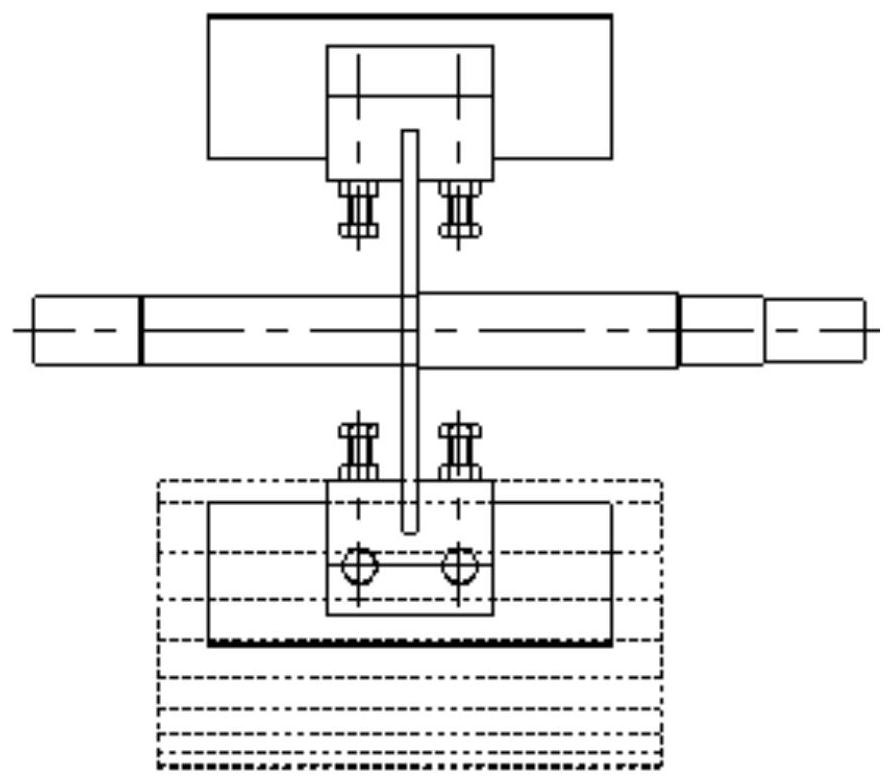

[0025] see Figure 2-7 , this embodiment is mainly aimed at figure 1 The part 2 in the shell is a peanut shelling drum with variable diameter and flexible plate. The shelling drum 2 has a shelling rotating part 201, and the shelling rotating part 201 includes a shelling disc 201b and its surroundings, etc. Some U-shaped support 201a of playing board that the angle is fixed radially, an L-shaped support plate 203 is arranged in the U-shaped support 201a of the playing board, and the L-shaped support plate 203 is positioned at the U-shaped groove width of the U-shaped support 201a of the playing board. The length of one end is less than the width of the U-shaped groove; the L-shaped suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com