Transport vehicle capable of automatically loading and unloading goods

A technology of automatic loading and unloading and transport vehicles, which is applied to the arrangement of loading and unloading vehicles, vehicles used for freight transportation, vehicles with elevated loading platforms, etc., which can solve the problem of inability to realize automatic loading and unloading of ground goods and containers, unfavorable energy saving, and restrictions on the convenience of cargo loading and unloading Sexuality, efficiency and other issues, to achieve the effect of improving convenience and efficiency, reducing labor intensity, and improving the degree of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the drawings and embodiments.

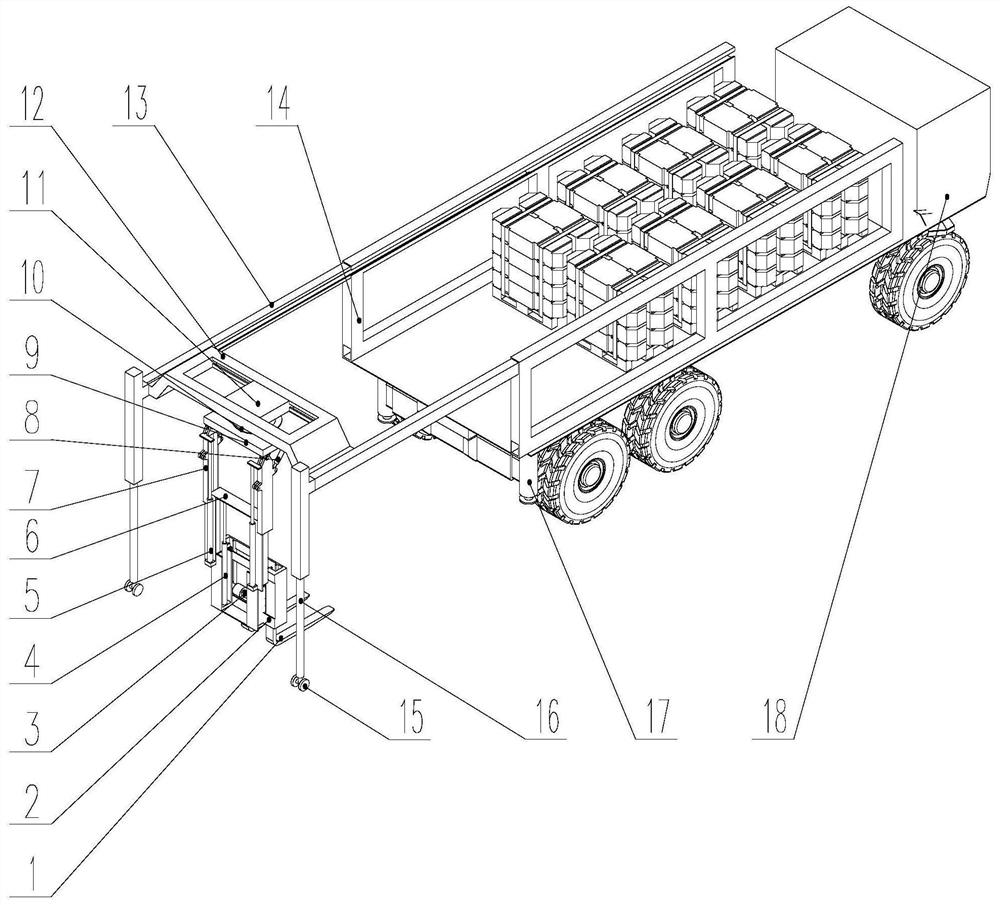

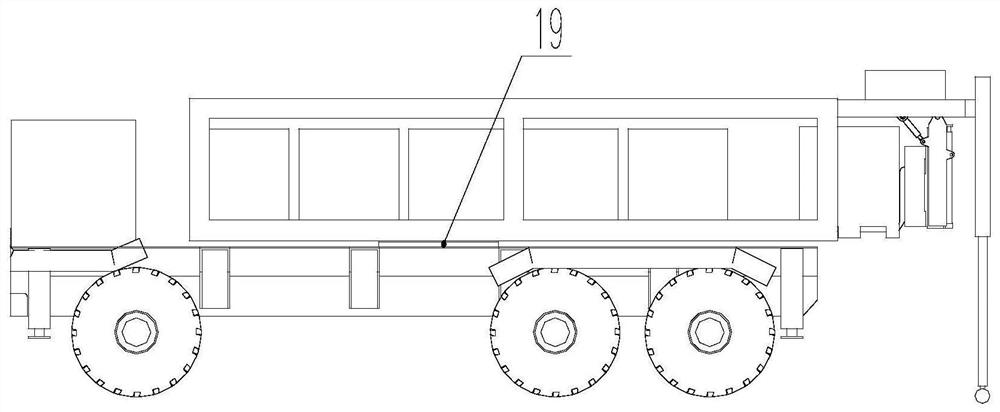

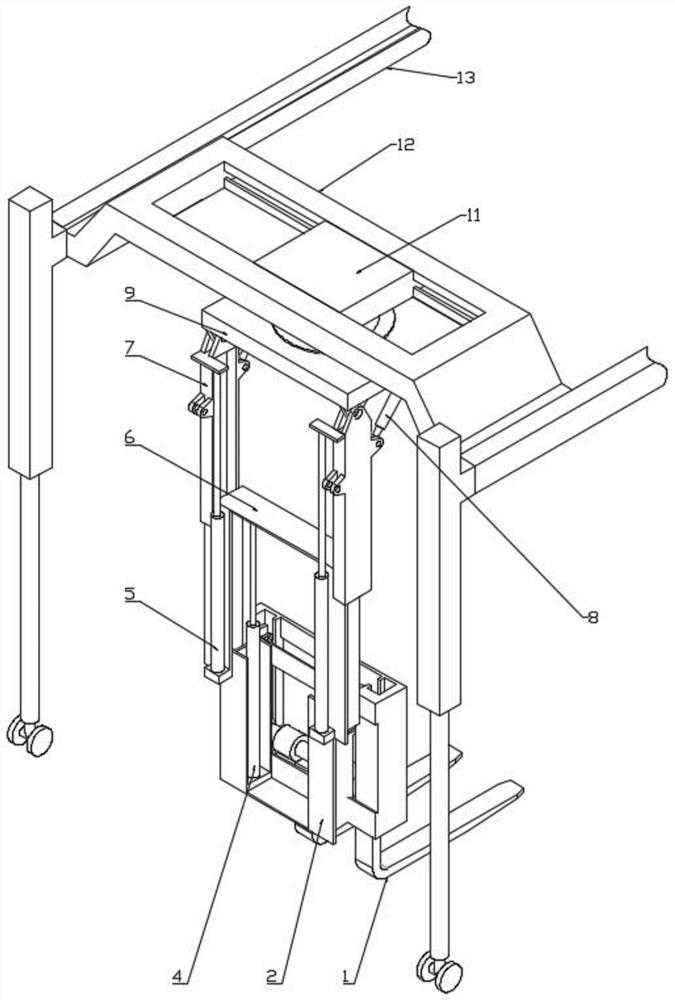

[0032] Such as Figure 1-3 As shown, the transport vehicle capable of automatically loading and unloading goods in this embodiment includes a car body 18, an upper loading platform, a supporting portal frame 14, a telescopic truss 13, a sliding truss 12, a traversing seat 11 and a working device; The platform slewing bearing 19 is assembled with the car body slewing, such as Figure 10 As shown, the upper loading platform can be rotated relative to the vehicle body as required, so as to expand the loading range; the supporting portal frame 14 is arranged on both sides of the upper loading platform, the upper loading platform and the supporting portal frame form a compartment, and the telescopic truss 13 and the support The gantry 14 is axially slidably assembled, the sliding truss 12 is axially slidably assembled with the telescopic truss 13, and the traverse seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com