A centrifugal model test device and method for simulating concrete face dam failure

A concrete face dam and centrifugal model test technology, applied in the direction of measuring devices, testing wear resistance, instruments, etc., can solve problems such as inability to study, different failure mechanisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

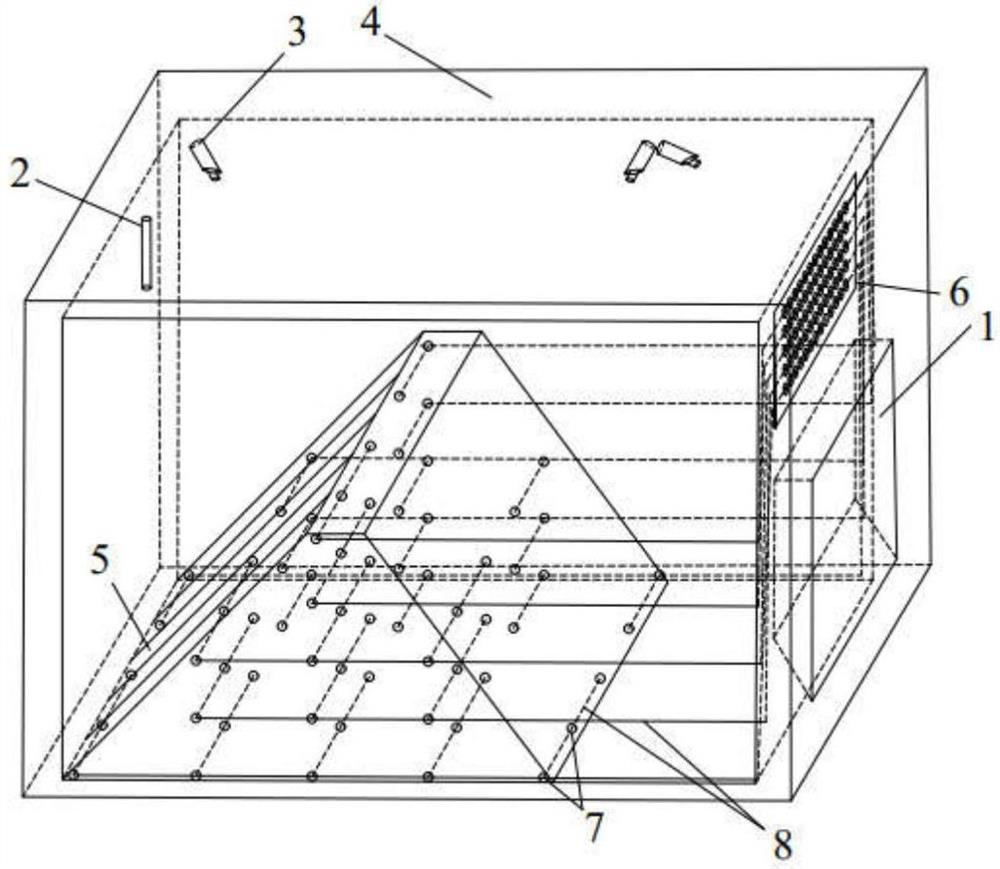

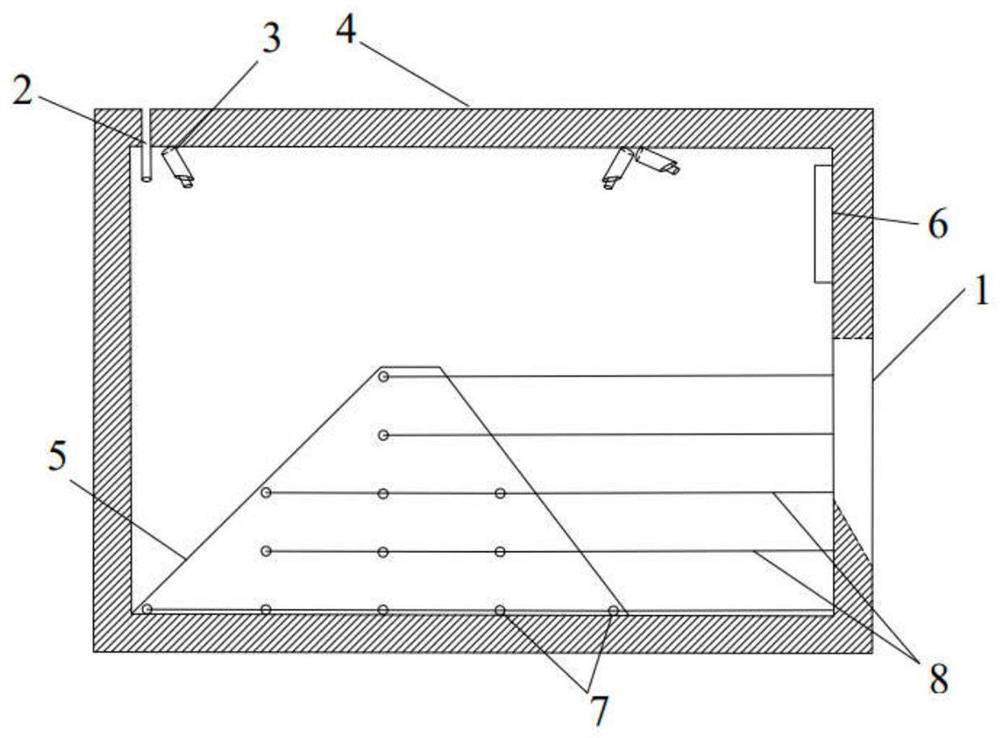

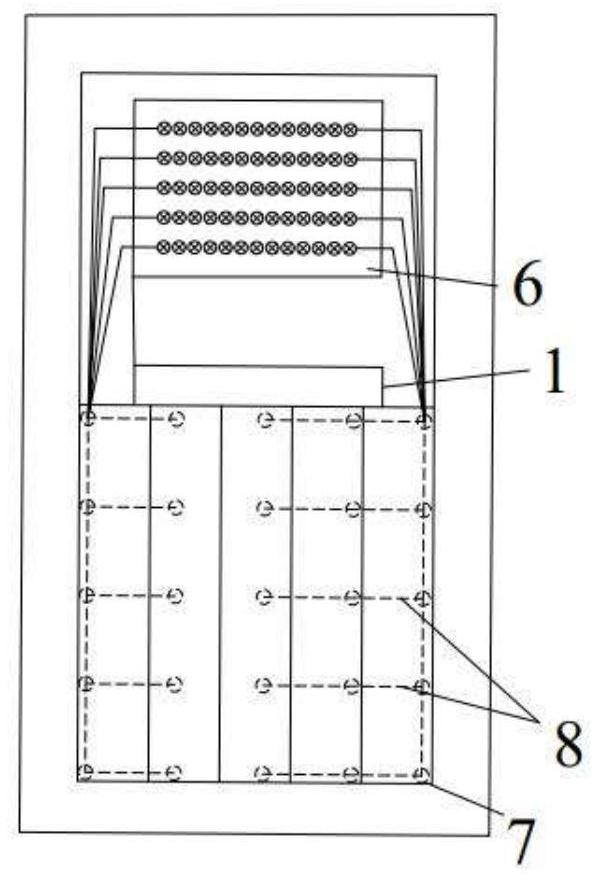

[0040] Such as Figure 1-3 , 5-6, a centrifugal model test device for simulating concrete face dam failure, including a model box 4 made of aluminum alloy, one side wall of the model box is provided with a water inlet 2, and the other side wall of the model box is opposite to the water inlet. A rectangular weir 1 for overflow is provided on the side wall, and an indicator light panel 6 is arranged on the side wall of the model box above the rectangular weir; a rockfill material is arranged in the model box, and the upstream side of the rockfill material is connected to the gypsum board 5, and the downstream side of the gypsum board According to the depth direction of the face plate dam, multiple photoresistors 7 are buried in layers in the rockfill material. The photoresistor model is LXD3526. The resistor is electrically connected with an indicator light on the indicator panel;

[0041] The model box above the gypsum board is equipped with a high-speed high-definition camera...

Embodiment 2

[0046] A centrifugal model test method for the failure of a concrete face dam, mainly comprising the following steps:

[0047] Step 1: Survey and measure the parameters of the rockfill and face material of the concrete face dam on site, and configure the gypsum board and rock fill materials with similar physical and mechanical properties to the actual physical and mechanical properties of the on-site face face dam. The rockfill material for the model is selected from the original rockfill material on site, which is crushed and sieved to make the centrifugal model.

[0048] The slope ratio and hydrological data of the concrete face dam on site were sampled and arranged to make the centrifuge model the same as the actual situation as much as possible. Multiple groups of undisturbed samples were selected for gradation tests at different locations on multiple exploration routes for rockfill materials for face-face dams. The main material of the rockfill material is stone, the par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com