Sewing equipment and sewing work distribution mode

A sewing and equipment technology, which is applied in the field of vehicle entry order management system, can solve the problems of rushing work, high communication costs, and affecting product quality in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

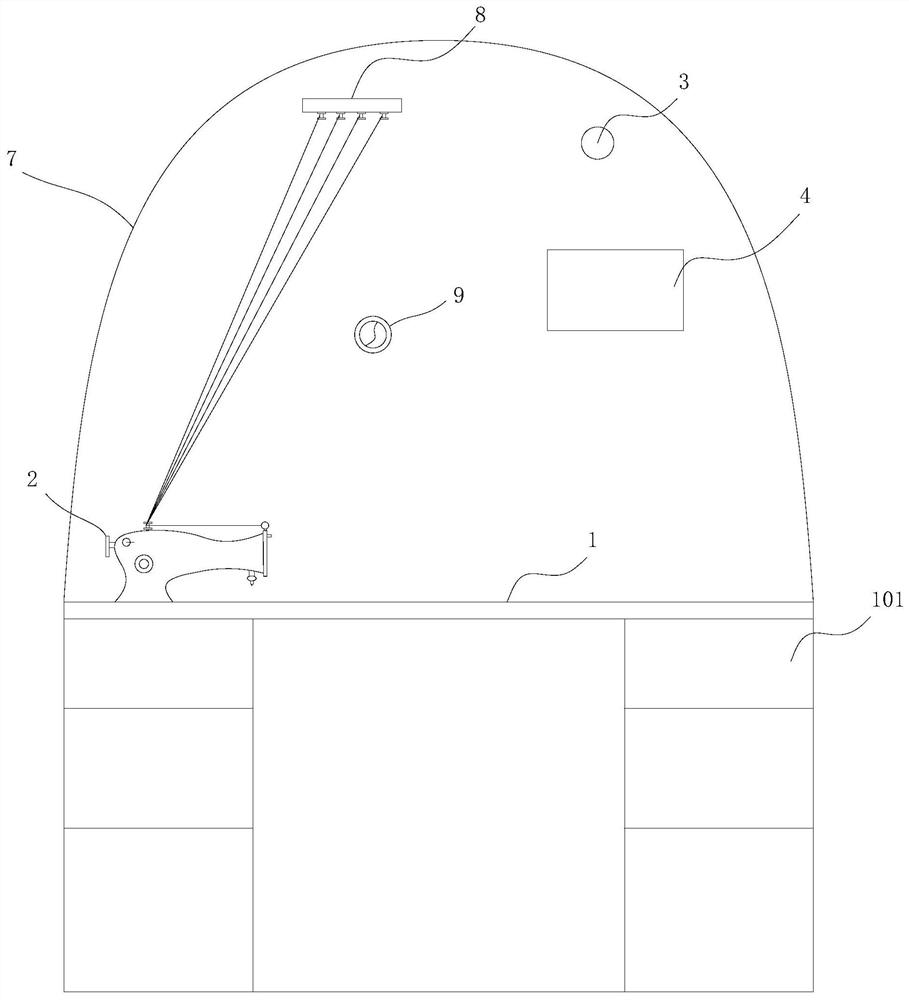

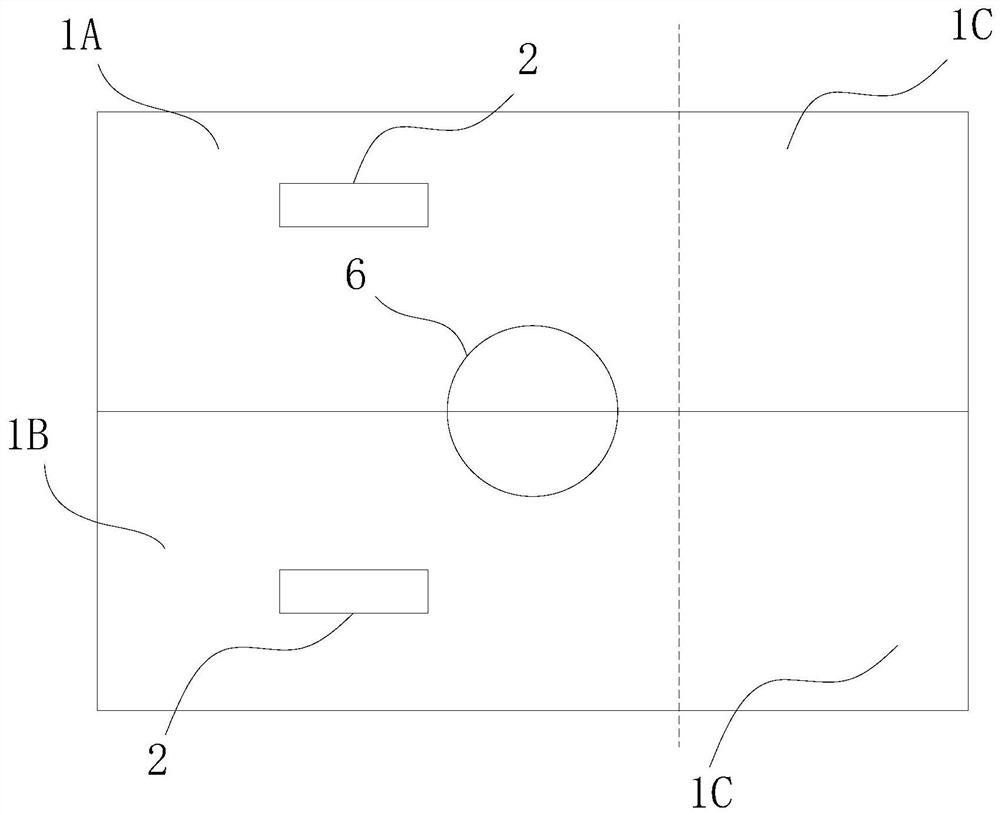

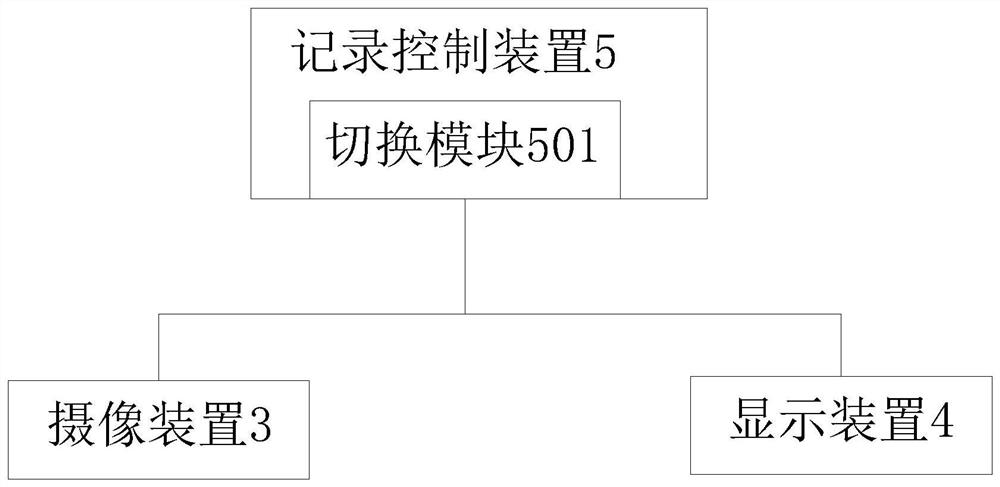

[0025] see Figure 1 to Figure 3 , a kind of sewing equipment, be provided with workbench 1, sewing machine 2, camera device 3, display device 4, the protective cover 7 that cover is arranged on the periphery; Said sewing machine 2 is arranged on the workbench 1, said display device 4, said The imaging device 3 is used to record the operation video of the operator, and the display device 4 is used to play sewing teaching information; it also includes a recording control device 5, and when the recording control device 5 is started, the display device 4 plays the corresponding process teaching information, the camera 3 starts to record the operation video of the operator; the recording control device 5 is provided with a switching module, the operator triggers the switching module 501, the video recording device 3 stops video recording, and integrates the recorded images into The operation record of the process; the display device 4 switches to the teaching video of the next pro...

Embodiment 2

[0030]A sewing work distribution mode is characterized in that: it includes a cloud control system and sewing equipment; the sewing equipment is provided with a workbench, a sewing machine, a camera, a display device and a recording control device; the sewing machine is arranged on the workbench, The display device, the camera device are used to record the operation video of the operator, and the display device is used to play sewing teaching information; the recording control device controls the start and stop of the display device and the camera device. The display device plays the teaching information of the corresponding process, and the camera device starts to record the operation video of the operator; The system claims the task, and the cloud control system sends the corresponding sewing teaching information to the display device; the cloud control system pre-stores an operating time standard for a process, and when the operation record time is less than or equal to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com