Automatic artificial board feeding device for production

A technology of automatic feeding and wood-based panels, applied in applications, household components, household appliances, etc., can solve the problems of single structure, slow speed, low efficiency, etc., and achieve the effect of increasing stability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

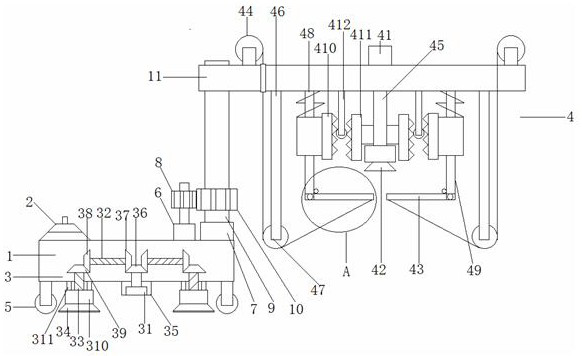

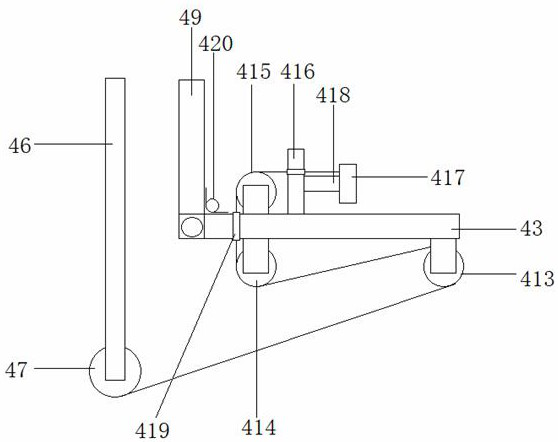

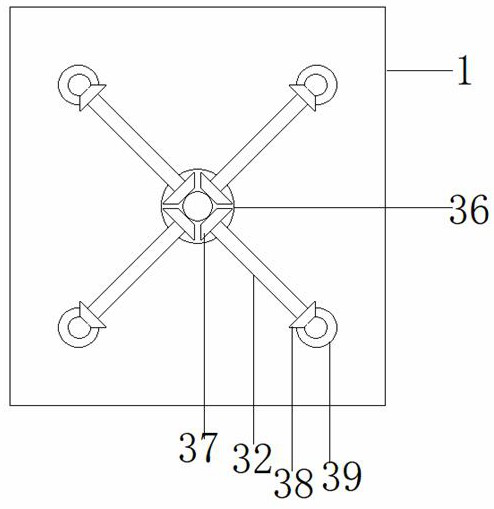

[0018] Such as Figure 1-4 As shown, an automatic feeding device for wood-based panels for production provided by the present invention at least includes a feeding vehicle 1, a counterweight 2, a transmission device 3 and a feeding device 4, and the bottom of the feeding vehicle 1 is provided with four A universal wheel 5, and the counterweight 2 is located at the left end of the transport truck 1, the transmission device 3 includes a first motor 31, a first screw 32, a second screw 33 and an anti-skid pad 34, the first screw 33 and an anti-slip pad 34. The motor 31 is positioned at the bottom of the transport truck 1, and the first motor 31 is provided with a protective cover 35, the first motor 31 is provided with a first bevel gear 36, and the number of the first screw mandrel 32 is four, And the first screw mandrels 32 are respectively loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com