FPC adhesive layer removing device for secondary recovery of touch screen mobile phone cover plate

A technology for secondary recycling and touch-screen mobile phones, which is applied in the directions of transportation and packaging, cleaning methods and utensils, solid waste removal, etc., and can solve the problems of touch-screen mobile phone cover damage and breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

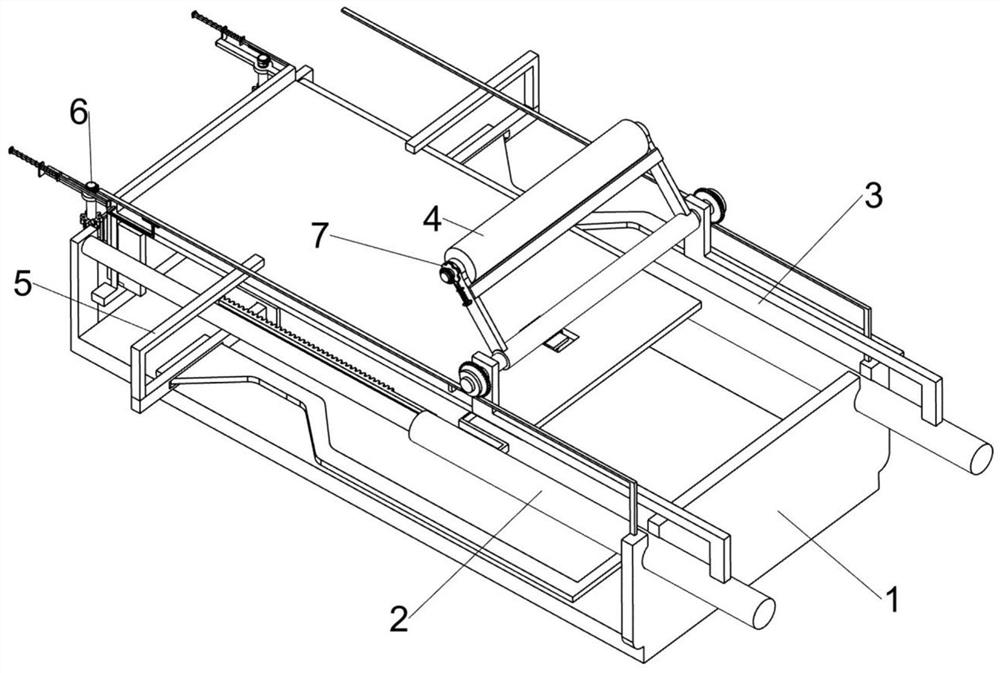

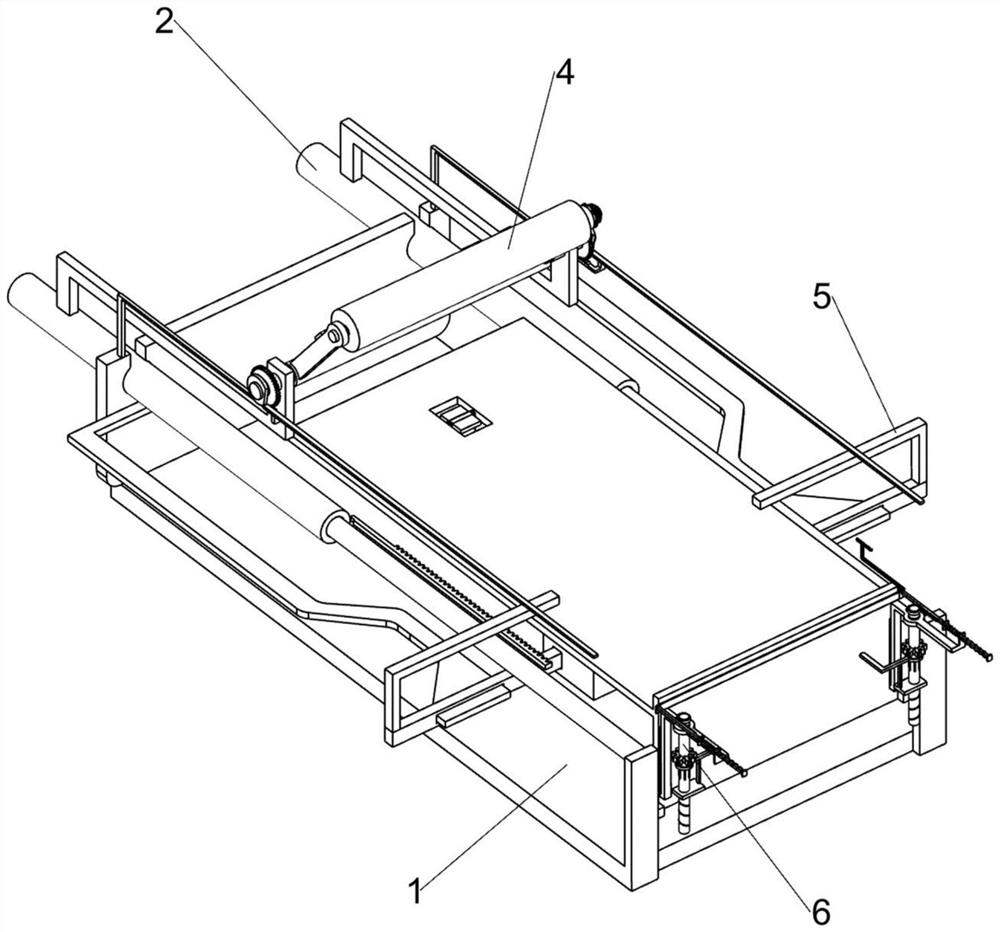

[0026] A kind of FPC adhesive layer removal device for secondary recovery of touch screen mobile phone cover plate, such as Figure 1-9 As shown, it includes a bottom plate 1, an electric push rod 2, a support frame 3, an overturning component 4, an auxiliary placement component 5, and a rubber strip cleaning component 6. Two electric push rods 2 are slidably connected to the bottom plate 1, and the electric push rod 2 is telescopic. The shaft is fixed to the bottom plate 1, the support frame 3 is fixed to the electric push rod 2, the turning component 4 is set on the support frame 3, the auxiliary placement component 5 is set on the electric push rod 2, and the auxiliary placement component 5 is used to assist the staff The touch screen mobile phone cover is placed on the workbench 62, and the base plate 1 is provided with a rubber strip cleaning assembly 6, which is used to scrape off the FPC rubber strip on the touch screen mobile phone cover.

[0027] The overturning assem...

Embodiment 2

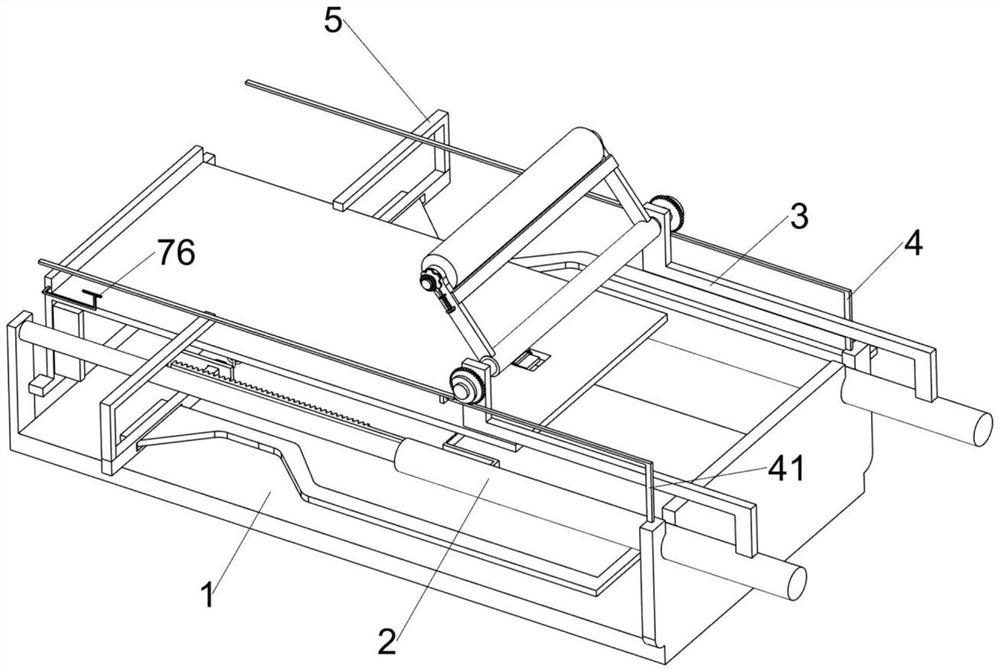

[0034] On the basis of Example 1, such as Figure 8 As shown, the rubber strip anti-sticking component 7 is included, and the rubber strip anti-sticking component 7 is arranged on the flipping component 4. The rubber strip anti-sticking component 7 is used to scrape off the FPC adhesive layer stuck on the rubber strip pushing roller 45, and the glue strip The strip anti-sticking assembly 7 includes a chuck 71, a clamping lever 72, a clamping spring 73, an overrunning clutch 74, a rotating gear 75 and a fixed rack bar 76. 44 upper sliding type is connected with clamping rod 72, and clamping rod 72 is used for clamping chuck 71, is connected with clamping spring 73 between clamping rod 72 and overturn frame 44, and clamping rod 72 and chuck 71 mutually contact, rubber strip pushing roller 45 is fixedly connected with overrunning clutch 74, fixedly connected with rotating gear 75 on the overrunning clutch 74, fixed rack bar 76 is fixedly connected on the workbench 62, fixed rack ...

Embodiment 3

[0037] On the basis of Example 2, such as Figure 9 As shown, a blocking assembly 8 is also included. The workbench 62 is provided with a blocking assembly 8. The blocking assembly 8 is used to block the cover plate of the touch screen mobile phone. The blocking assembly 8 includes a triangular plate 81, a torsion spring 82 and a fixed baffle 83. A triangular plate 81 is hinged on the workbench 62. The triangular plate 81 is used to block the cover plate of the touch screen mobile phone. A torsion spring 82 is connected between the triangular plate 81 and the workbench 62. The electric push rod 2 is fixedly connected with a fixed baffle plate 83. The baffle 83 is used to block the triangular plate 81 , and the fixed baffle 83 away from the electric push rod 2 is in contact with the triangular plate 81 .

[0038] When the electric push rod 2 and its upper device move towards the direction of the fixed rail rod 63, the fixed baffle 83 is separated from the triangular plate 81, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com