Balance cabin for ferris wheel

A technology of balancing cabin and Ferris wheel, applied in the direction of large runner, Russian swing, entertainment, etc., can solve the problems of small load bearing, poor eccentric load comfort, high cost, etc., to reduce equipment cost, ensure self-balancing, maintenance and replacement easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with the accompanying drawings and specific embodiments, the present invention will be described in further detail:

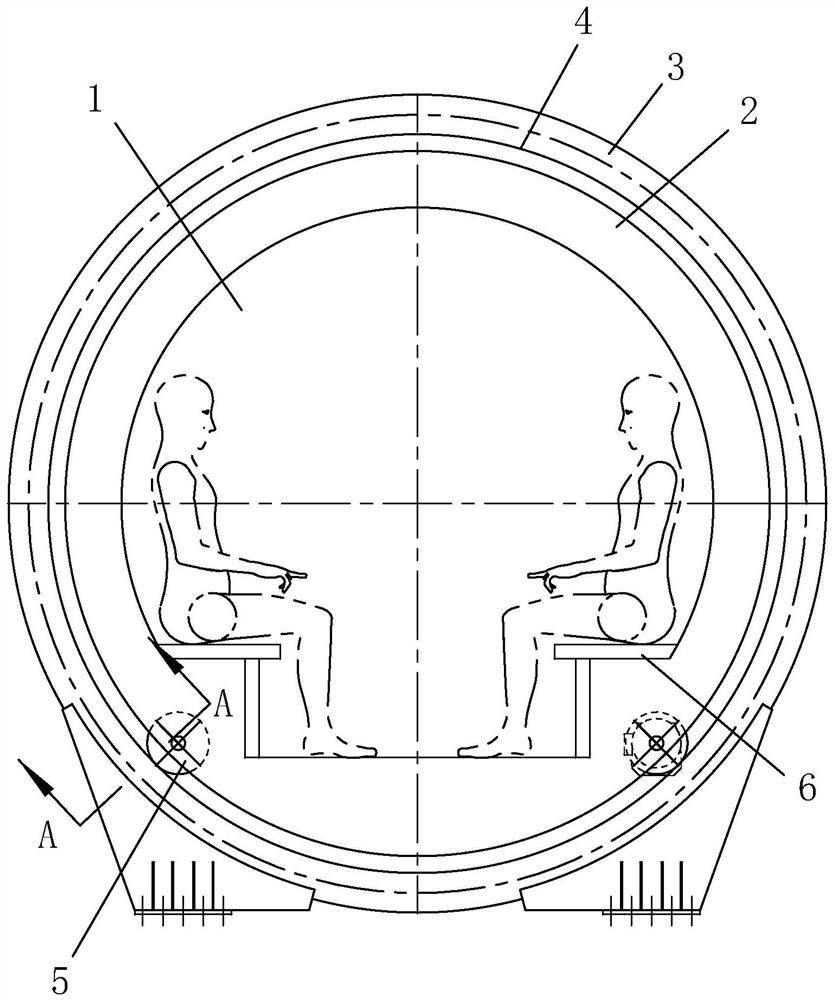

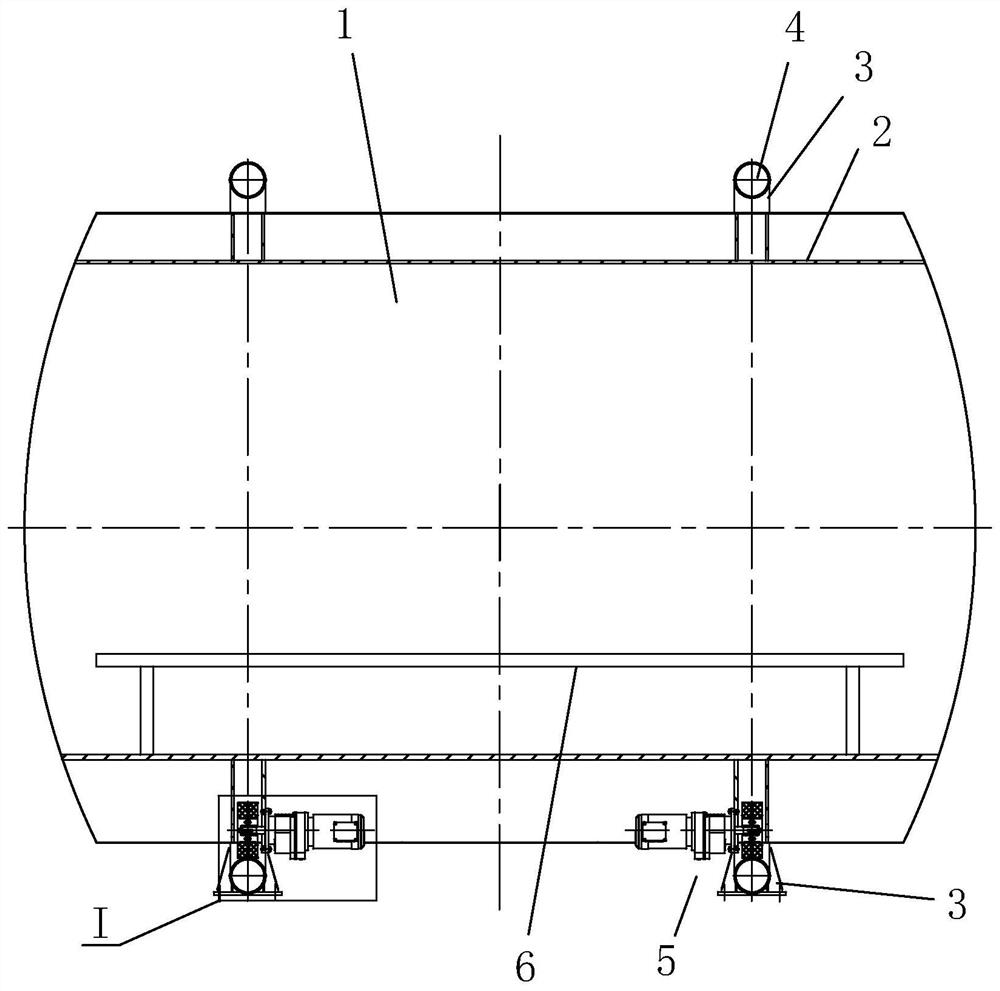

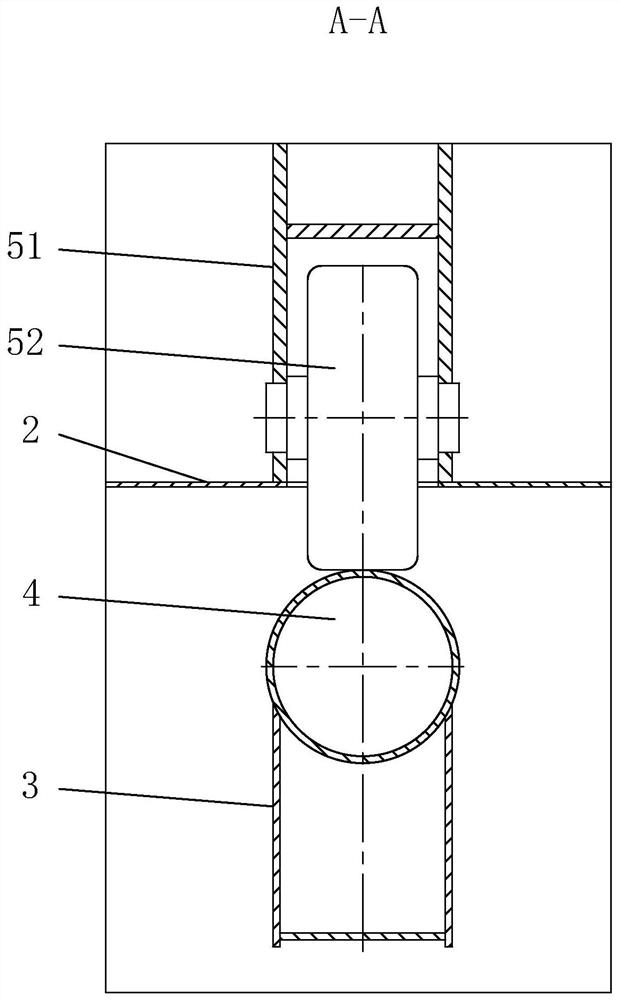

[0042] as attached figure 1 to attach Figure 12 As shown, a balance cabin for a Ferris wheel includes a rotating cabin 1, and a seat 6 for tourists is arranged inside the rotating cabin 1; at least one inner ring is sleeved on the rotating cabin 1 2. The inner ring 2 is fitted with an outer ring 3 for fixed connection with the turntable of the Ferris wheel; furthermore, the outer ring is fixedly connected with the turntable of the Ferris wheel through a flange, which saves the cockpit hanging structure, effectively Reduce equipment costs. The outer ring 3 or the inner ring 2 is provided with an arc-shaped running track 4 , and the cross section of the running track 4 is circular. The inner ring 2 or the outer ring 3 is surrounded by several wheel train components 5 which are in rolling contact with the running track 4 so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com