Four-way shuttle vehicle continuous positioning system and method

A positioning system and shuttle technology, applied in electromagnetic radiation induction, instruments, induction recording carriers, etc., can solve problems such as large positioning errors, economic losses, equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the accompanying drawings and examples.

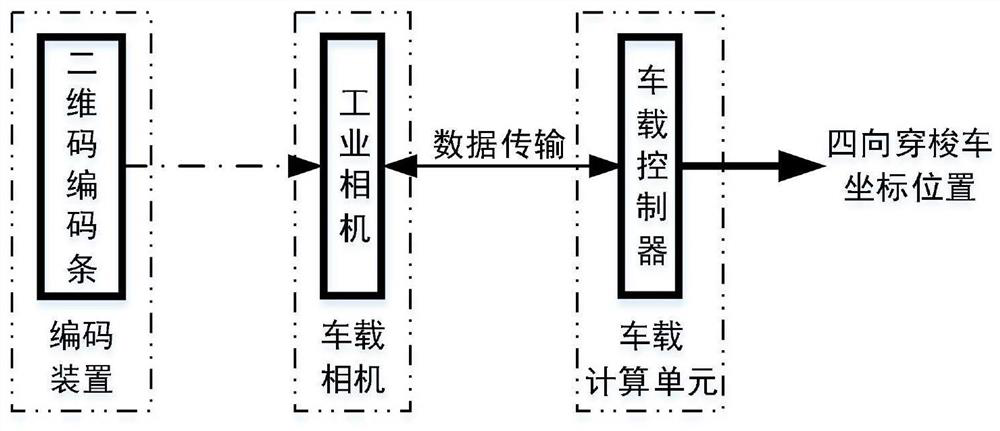

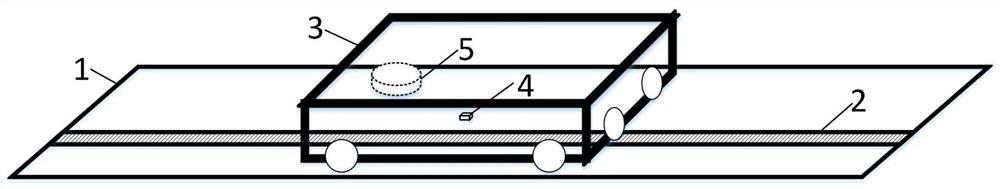

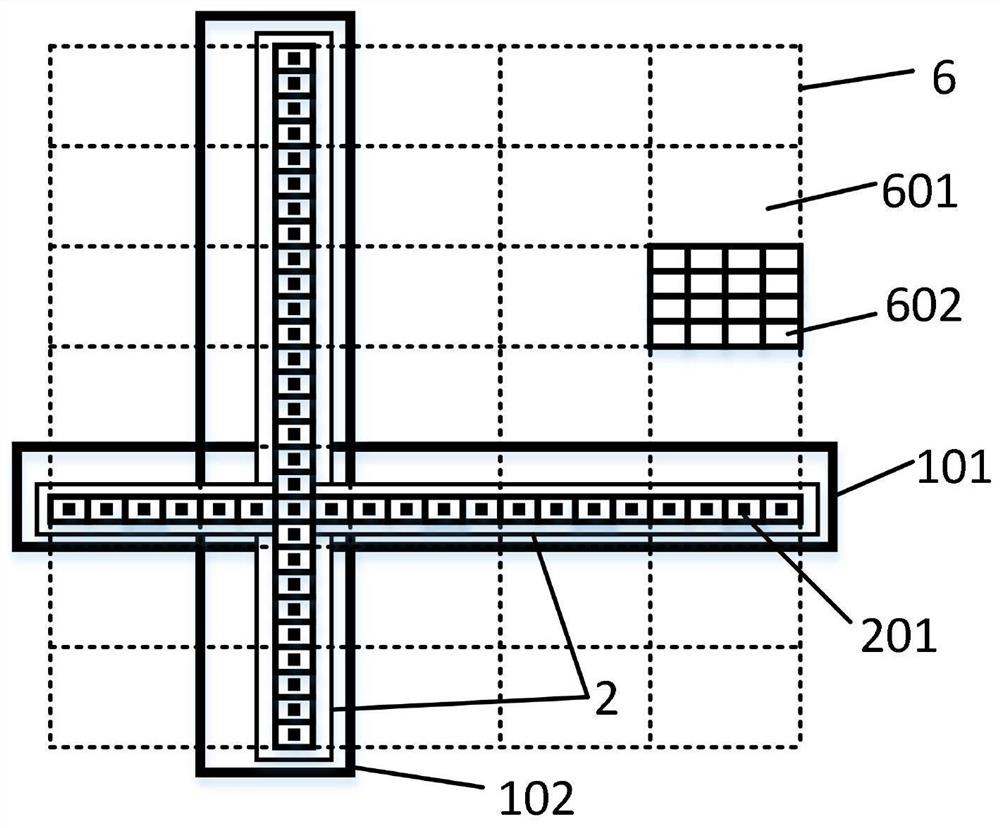

[0034] See Figure 1-4 A four-way shuttle continuous positioning system, including shelf channels, coding strips, industrial cameras, controllers, and four-way shuttle; coding strips are mounted at the bottom of the shelf channel; the QR code is sticked to the designated position on the coded bar The QR code is facing up, facing the bottom of the four-way shuttle; the industrial camera mounted below the four-way shuttle is scanned with a coded bar posted with a QR code; the industrial camera is connected to the controller.

[0035] The four-way shuttle, its work planar area is divided into a mesh-like size cell, four-way, longitudinally passing the same column unit, and the four-way shuttle laterally passing the same line unit Composition transverse channels.

[0036] The cell includes a cellular product space and a cell channel, and the longitudinal di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com