A kind of preparation method of chiral α-methyl arylethylamine

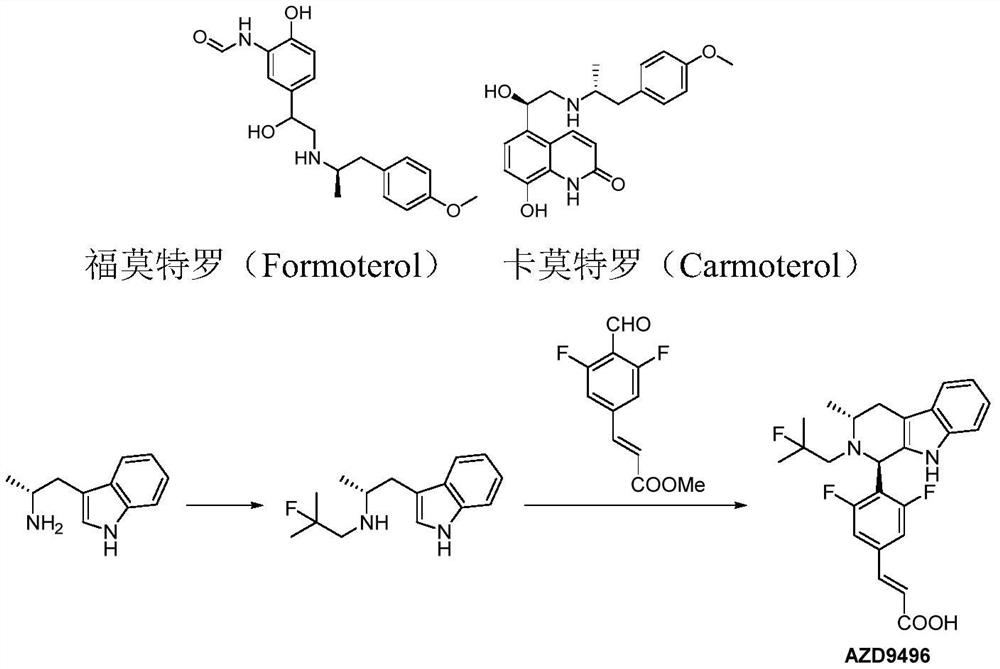

A methyl arylethylamine and chirality technology, which is applied in the field of preparation of chiral α-methyl arylethylamine, can solve the problems of being unsuitable for large-scale industrial production, low atom utilization rate and high production cost, and can avoid a large number of The generation of solid waste and isomers, the effect of overcoming the problem of column chromatography separation, and reducing the hidden danger of production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

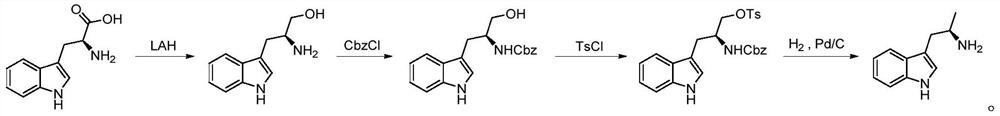

Method used

Image

Examples

Embodiment 1

[0054] (1) Boc-L-tryptophan methyl ester (318.4g, 1.0mol) was added into a 5L three-necked flask, ethanol (2.5L) was added, and sodium borohydride (95.1g, 2.5mol) was added under temperature control at 0-10°C , and react at 30°C for 10h after the addition. Saturated ammonium chloride solution (1.5L) was added dropwise under temperature control at 0-5°C, and the ethanol was evaporated under reduced pressure. Extracted twice with ethyl acetate (2 L). The organic phases were combined, dried over sodium sulfate, concentrated under reduced pressure, and slurried with n-heptane to obtain 275.7 g of the product Boc-L-tryptophanol with a yield of 95% and a purity of 99.1%.

[0055] (2) Boc-L-tryptophanol (145.0g, 0.5mol) obtained in step (1) was added in a 5L there-necked flask, and dichloromethane (1.5L), triethylamine (111.0g, 1.1mol), Imidazole (102.0 g, 1.5 mol) was added dropwise to thionyl chloride (65.5 g, 0.55 mol) under temperature control at 0-5 °C, and the reaction was in...

Embodiment 2

[0060] The difference from Example 1 is that in step (3), anhydrous lithium chloride is replaced with anhydrous zinc chloride, and the rest are the same.

[0061] The reaction finally obtained 27.1 g of the product with a yield of 78% and a purity of 99.2%.

Embodiment 3

[0063] Different from Example 1, step (3) was changed to add the sulfonamide compound (70.5g, 0.2mol) obtained in step (2) in a 2L there-neck flask, and diethylene glycol dimethyl ether (1L) was added. , sodium borohydride (15.2g, 0.4mol), anhydrous lithium chloride (54.4g, 0.4mol), react at 80°C for 24h. The reaction solution was added to a 4M hydrogen chloride-ethyl acetate solution (150 mL) at a temperature of 5-10 °C, and the reaction was carried out at 30 °C for 12 h. After precipitation under reduced pressure, saturated sodium bicarbonate solution was added, extracted twice with ethyl acetate (400 mL), dried over sodium sulfate, and concentrated under reduced pressure to obtain the crude product, which was recrystallized from ethyl acetate and n-heptane. The rest are the same.

[0064] The reaction finally obtained 23.8 g of product with a yield of 68% and a purity of 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com