Lifting appliance and method for prefabricated part

A technology of prefabricated components and hoisting, which is applied in the direction of transportation and packaging, load hanging components, etc., and can solve problems such as poor compatibility, safety accidents, prefabricated components hoisting slippage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

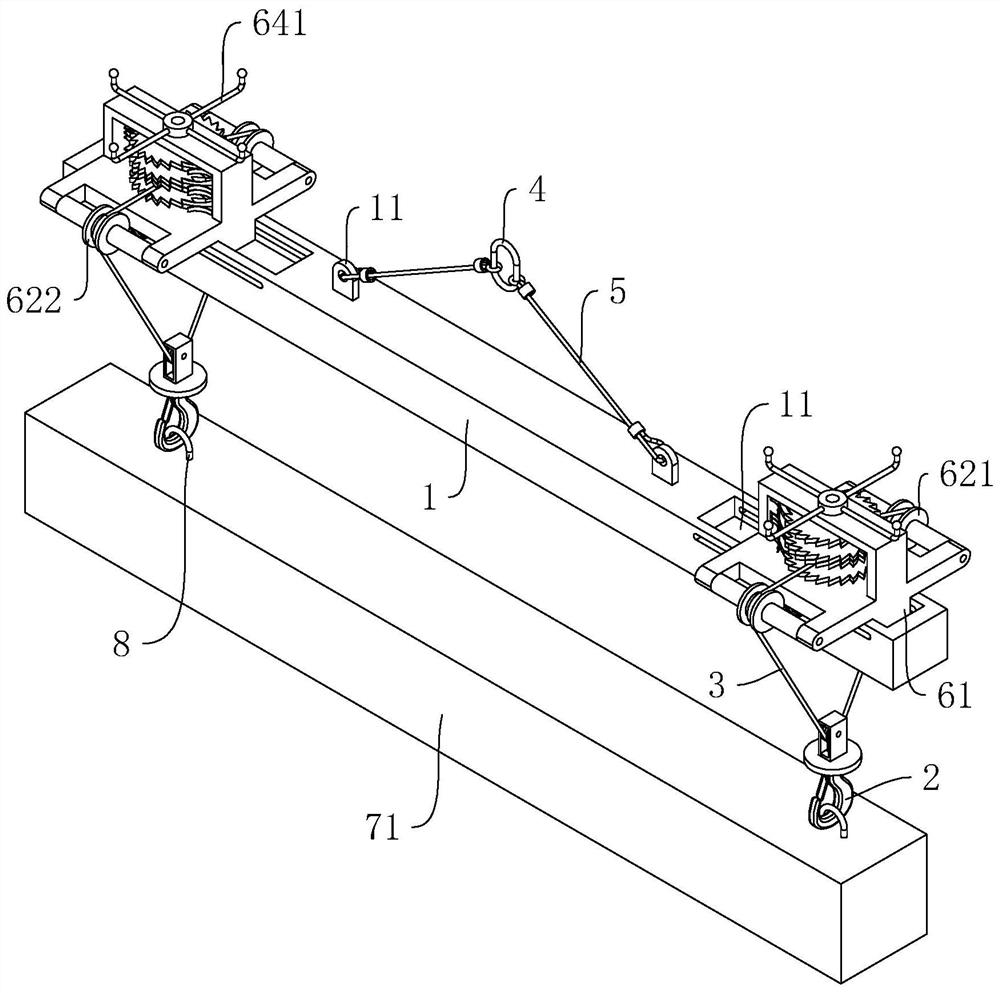

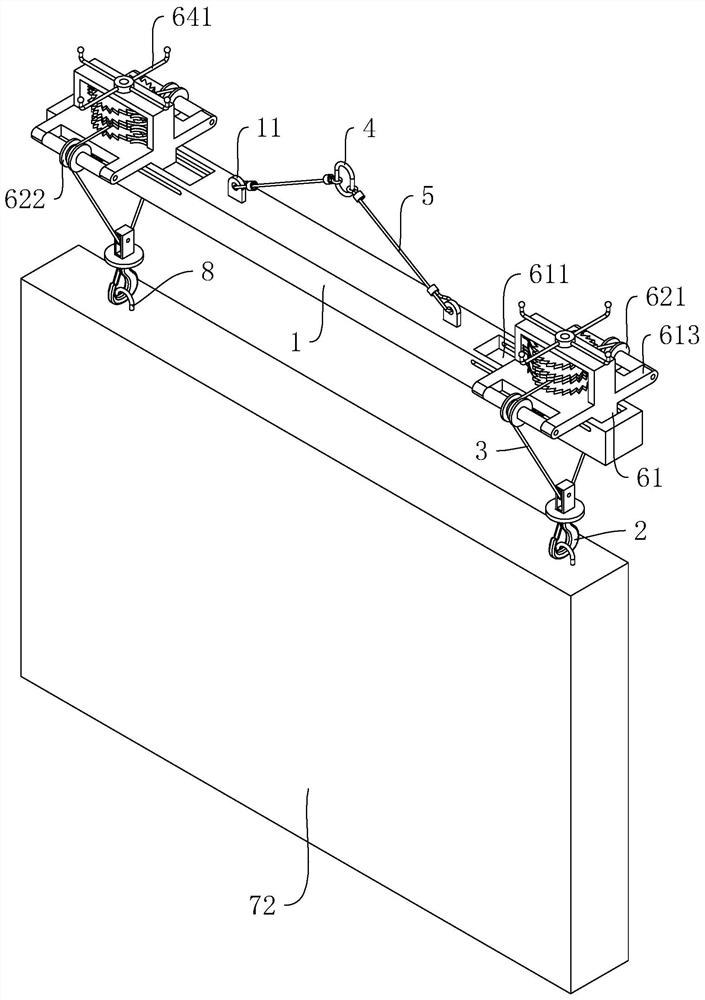

[0040] The following is attached Figure 1-7 The application is described in further detail.

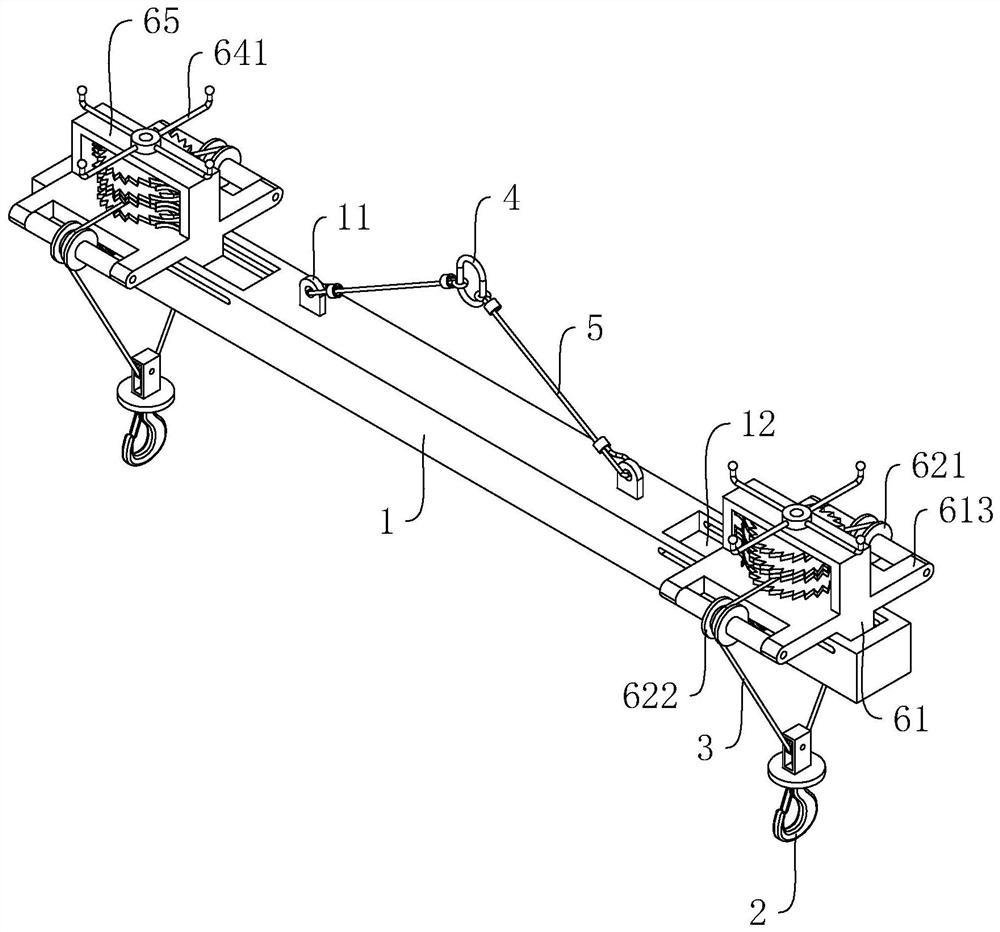

[0041] The embodiment of the application discloses a hoisting sling for a prefabricated component. refer to figure 1 , The hoisting spreader includes a bearing steel beam 1, a hoisting mechanism and a tower crane connecting mechanism.

[0042] The load-bearing steel girder 1 is a steel girder with strong load-bearing capacity and not easily deformed or broken when under pressure, so that the load-bearing steel girder 1 can bear the weight of the prefabricated components. The hoisting mechanism is arranged at both ends of the load-bearing steel beam 1 in the length direction, and the hoisting mechanism is used for connecting the load-bearing steel beam 1 with the prefabricated components. The load-bearing steel beam 1 is provided with a tower crane connection mechanism between the two hoisting mechanisms, and the tower crane connection mechanism is used to connect the load-bearing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com