Stress luminescence type anti-forgery ink, preparation method and use method

A stress luminescence, anti-counterfeiting ink technology, applied in the field of ink, can solve the problems of poor anti-counterfeiting strength, low safety factor, unstable product quality, etc., and achieve the effect of good printing suitability, high production efficiency, and high anti-counterfeiting identification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

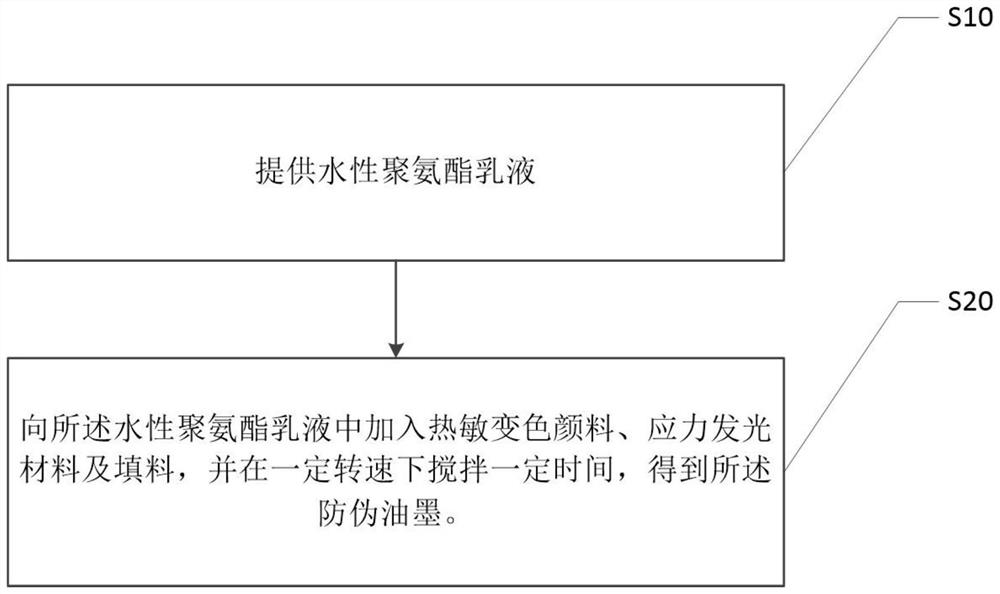

[0037] In order to solve the above technical problems, this application also discloses a preparation method of stress-luminescent anti-counterfeiting ink, please refer to figure 1 , wherein, the method is used to prepare the above-mentioned stress-luminescent anti-counterfeiting ink, and the method comprises the steps of:

[0038] S10, providing water-based polyurethane emulsion.

[0039] In the step S10, the polyisocyanate is mixed with the oligomeric polyol, stirred with a high-speed disperser at 400-600r / min, heated to 70-90°C for 1.5-2.5 hours, cooled to 60°C, and then added with hydrophilic chain extension The agent is continuously reacted for 40-80 minutes to obtain a water-based polyurethane prepolymer, and the temperature is continued to drop to 25-35°C to add a water-based solvent, and the stirring is continued to obtain the water-based polyurethane resin emulsion.

[0040] S20. Add heat-sensitive color-changing pigments, stress-luminescent materials and fillers to t...

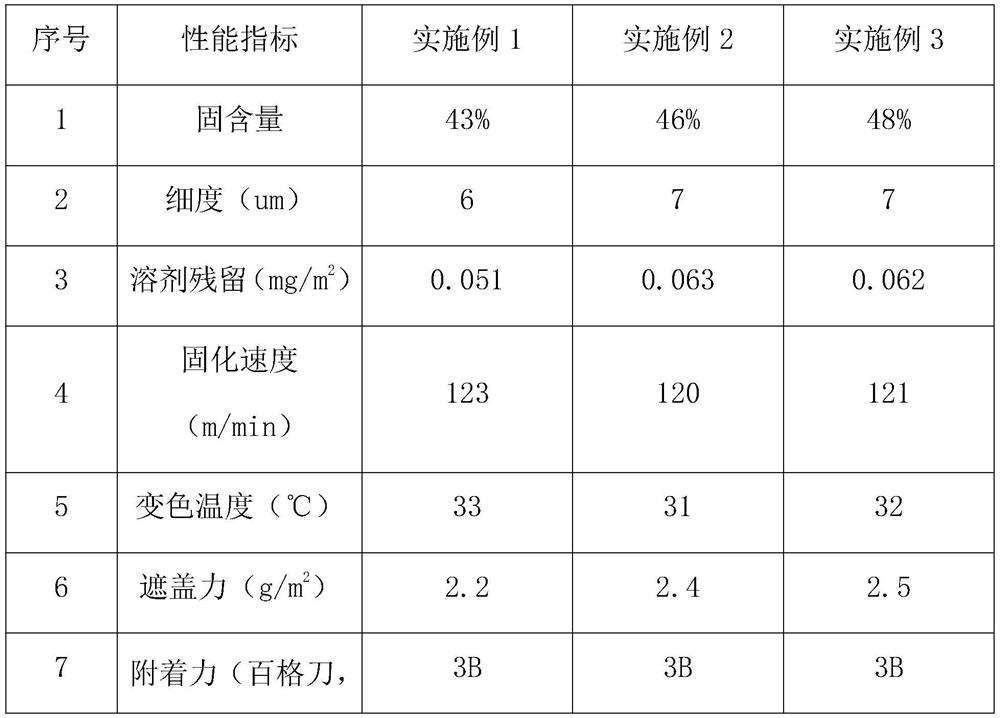

Embodiment 1

[0054] Mix polyisocyanate with oligomeric polyol, stir with a high-speed disperser at 400r / min, heat to 90°C for 1.5 hours, cool down to 60°C and then add a hydrophilic chain extender to continue the reaction for 80 minutes to obtain a waterborne polyurethane prepolymer, continue Lower the temperature to 25° C., add an aqueous solvent, and continue stirring to obtain the aqueous polyurethane resin emulsion 1.

[0055] Add heat-sensitive color-changing pigments, stress-luminescent materials and fillers to the water-based polyurethane resin emulsion 1, and stir for 20 minutes using a high-speed disperser at a speed of 1400 r / min.

[0056] After that, continue to add additives, adjust the pH value to 9.5, and stir at 600r / min for 80 minutes. During the process, continue to add water-based solvent to adjust its viscosity to 30s (Zion 4# cup, 25°C) to obtain the stress Luminous anti-counterfeiting ink1.

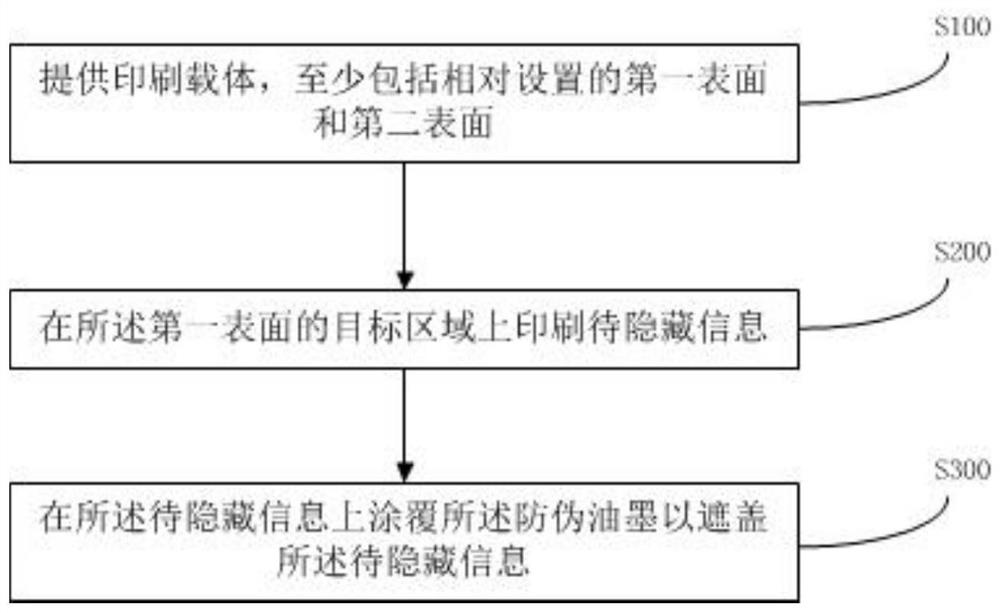

[0057] On the second surface of the printing carrier, the position correspon...

Embodiment 2

[0059] Preparation of stress-luminescent anti-counterfeiting ink:

[0060] Mix polyisocyanate with oligomeric polyol, stir with a high-speed disperser at 500r / min, heat to 80°C for 2 hours, cool down to 60°C and then add a hydrophilic chain extender to continue the reaction for 60 minutes to obtain a waterborne polyurethane prepolymer, continue Lower the temperature to 30° C., add an aqueous solvent, and continue stirring to obtain the aqueous polyurethane resin emulsion 2.

[0061] Add heat-sensitive color-changing pigments, stress-luminescent materials and fillers to the water-based polyurethane resin emulsion 2, and stir for 30 minutes using a high-speed disperser at a speed of 1200 r / min.

[0062] After that, continue to add additives, adjust the pH value to 9, and stir at 750r / min for 60 minutes. During the process, continue to add aqueous solvent, adjust its viscosity to 30s (Zion 4# cup, 25°C), and obtain the stress Luminous anti-counterfeiting ink2.

[0063] On the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com