Sewage recycling treatment equipment for municipal construction

A kind of sewage treatment equipment and technology of treatment equipment, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of moving at any time, limited sewage, unfavorable work efficiency, etc. problems, to achieve the effect of convenient cleaning or replacement, avoiding trouble, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

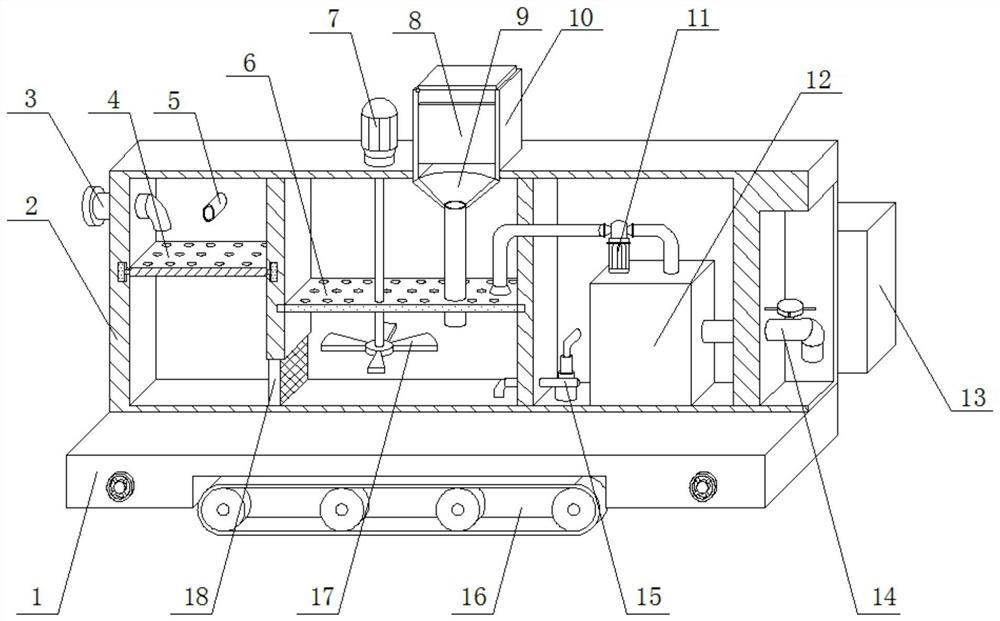

[0032] see Figure 1-Figure 8 , the present invention provides a sewage recycling treatment equipment for municipal construction, comprising a base 1, a sewage treatment equipment body 2 is fixedly installed above the base 1, a water inlet pipe 3 is fixedly installed on the upper end of the sewage treatment equipment body 2, and the water inlet pipe 3 The circulation pipe 5 is fixedly installed at the rear, the first filter plate 4 is installed movable inside the sewage treatment equipment body 2, the third filter plate 18 is fixedly installed under the first filter plate 4, and the right side of the first filter plate 4 is fixedly installed The second filter plate 6, a reagent box 10 is fixedly installed above the second filter plate 6, a funnel 9 is fixedly installed below the reagent box 10, and a hollow tube is fixedly installed below the funnel 9, and the hollow tube runs through the second filter plate 6 , the left side of the reagent box 10 is fixedly installed with the...

Embodiment 2

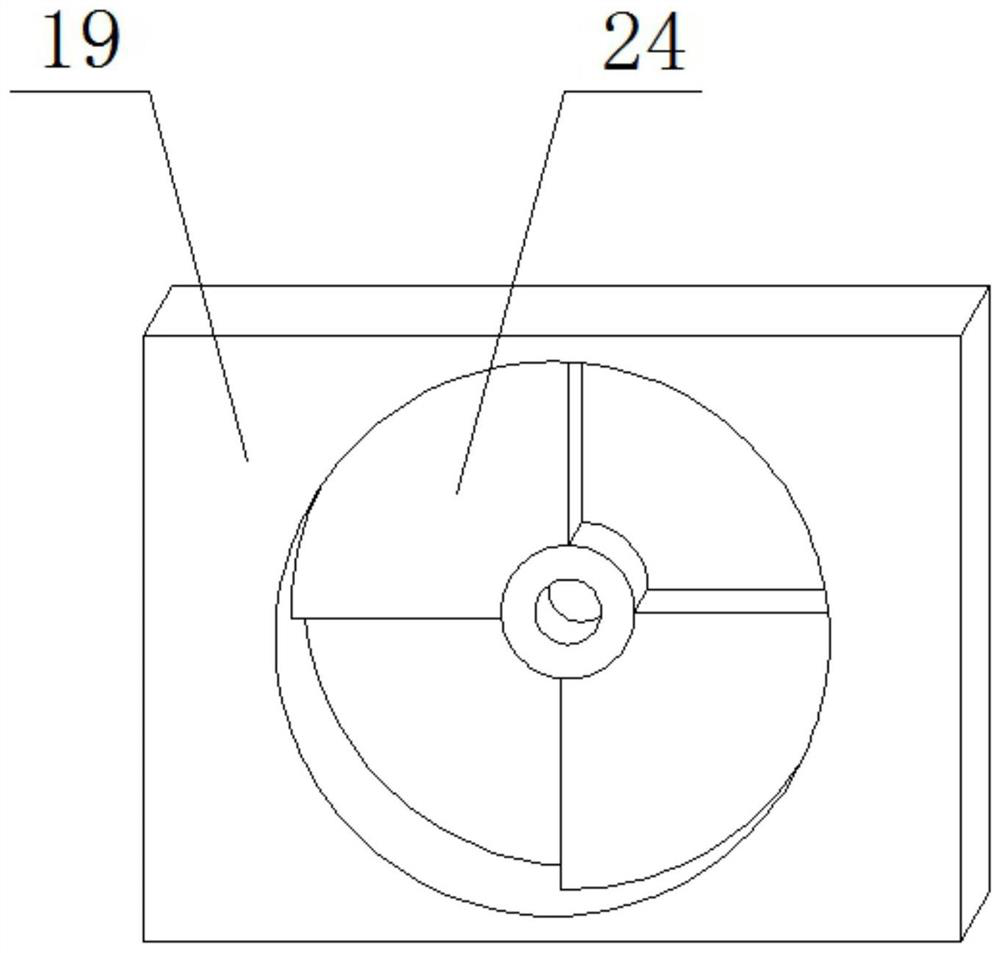

[0035] like Figure 1-6 As shown, the difference between this embodiment and Embodiment 1 is that a partition 8 is fixedly installed in the middle of the reagent box 10, and one end of the pressure sensor 22 is fixedly installed on the left and right sides below the bottom plate 19. The other end of 22 is fixedly installed on the top of fixed block 23; The inside of bottom plate 19 is fixedly installed with second baffle plate 24, and first baffle plate 21 and second baffle plate 24 are fan-shaped structures, and second motor 20 and first baffle plate The plates 21 are movably connected by a rotating shaft, and the rotating shaft runs through the second baffle plate 24; the left and right ends of the first filter plate 4 are fixedly equipped with sliders 30, the slider 30 is a T-shaped structure, and the rear of the first filter plate 4 is fixed The first spring 25 is installed, and the first filter plate 4 and the sewage treatment equipment body 2 are flexibly connected by th...

Embodiment 3

[0038] like Figure 1-8 As shown, the difference between this embodiment and Embodiments 1 and 2 is that wheels 32 are movably installed at the left and right ends of the bottom of the base 1, and the bottom surface of the wheels 32 is higher than the bottom surface of the crawler tire 16; the front of the base 1 The surface is movable with a turntable 31, and the turntable 31 and the wheel 32 are connected through a gear 34, a rack 35 and a connector 33; a circulation pipe 5 is fixedly installed at the rear upper end of the sewage treatment equipment body 2, and the circulation pipe 5 is connected to the desilting pump. 15 are connected; the rear of the sewage treatment equipment body 2 is fixedly installed with a control box 13, the control box 13 and the pressure sensor 22 are connected by signals, and the control box 13 controls the first motor 7, the water pump 11, the desilting pump 15 and the second Motor 20.

[0039] In this embodiment, because the environment of muni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com