Non-coaxial type double-layer linear sorting machine

A kind of sorting machine and double-layer technology, applied in the field of logistics, can solve the problems of easy falling of goods, shaking of trolleys, difficulty in adapting, etc., and achieve the effect of improving stability, preventing goods from falling, and improving loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention will be described in detail below in conjunction with examples. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make some adjustments and improvements without departing from the concept of the present invention; these all belong to the protection scope of the present invention.

[0031] The invention provides a non-axial double-layer linear circulation lifting cross-belt sorter.

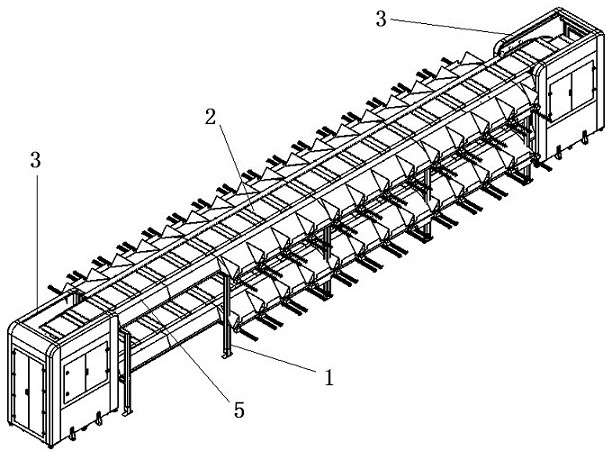

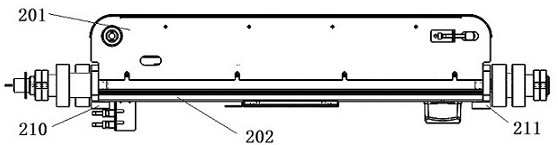

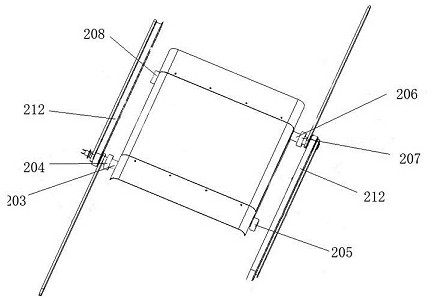

[0032] like figure 1 As shown, the non-axial double-layer linear circulation lifting cross-belt sorter includes a support frame 1, a sorting trolley 2, and a support box 3. The support box 3 is arranged at both ends of the support frame, and the support frame 1. A pair of horizontal slide rails 4 with the same direction and parallel to the plane are provided above and below. A number of sorting trolleys 2 are seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com