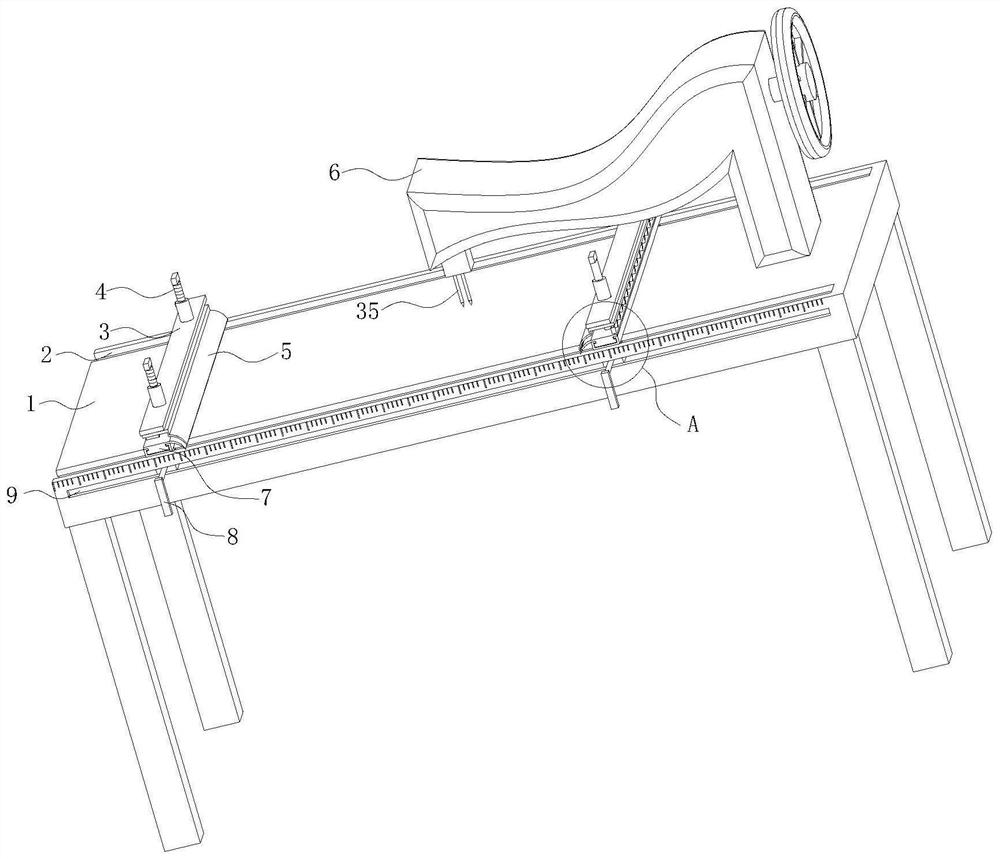

Double-chain stitch sewing machine

A technology of sewing machine and chain thread, which is applied in the direction of sewing machine components, sewing machine needle holder, sewing equipment, etc., can solve the problems that the sewing thread spacing cannot be equal, and the sewing thread is not in a straight line, etc., so as to improve the neatness of the stitches and improve the quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0032] As an embodiment of the present invention, the upper surface of the movable plate 3 is provided with a circular through groove 18; the top of the movable plate 3 corresponding to the circular through groove 18 is fixedly provided with an internal thread pipe 17; The internal screw thread of described internally threaded pipe 17 is connected with threaded rod 4; The top of the spring that is connected with described elastic pressure plate 15 is connected with the bottom end of threaded rod 4, and the bottom end of spring is connected with the top edge of rotating ball 40, The rotating ball 40 is movably arranged in the spherical chute 41 at the top of the elastic pressing plate 15; the outer diameter of the spring is less than the inner diameter of the circular through groove 18; during work, the elastic pressing plate 15 and the guide slide plate 7 can be changed by rotating the threaded rod 4. The distance between them, and then change the distance between the flexible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com