Novel rice milling chamber

A new type of rice grain technology, which is applied in the field of rice milling machines, can solve the problems of changing screens and uneven rice grain grinding, and achieves the effects of easy disassembly, reduced insufficient grinding, and uniform collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

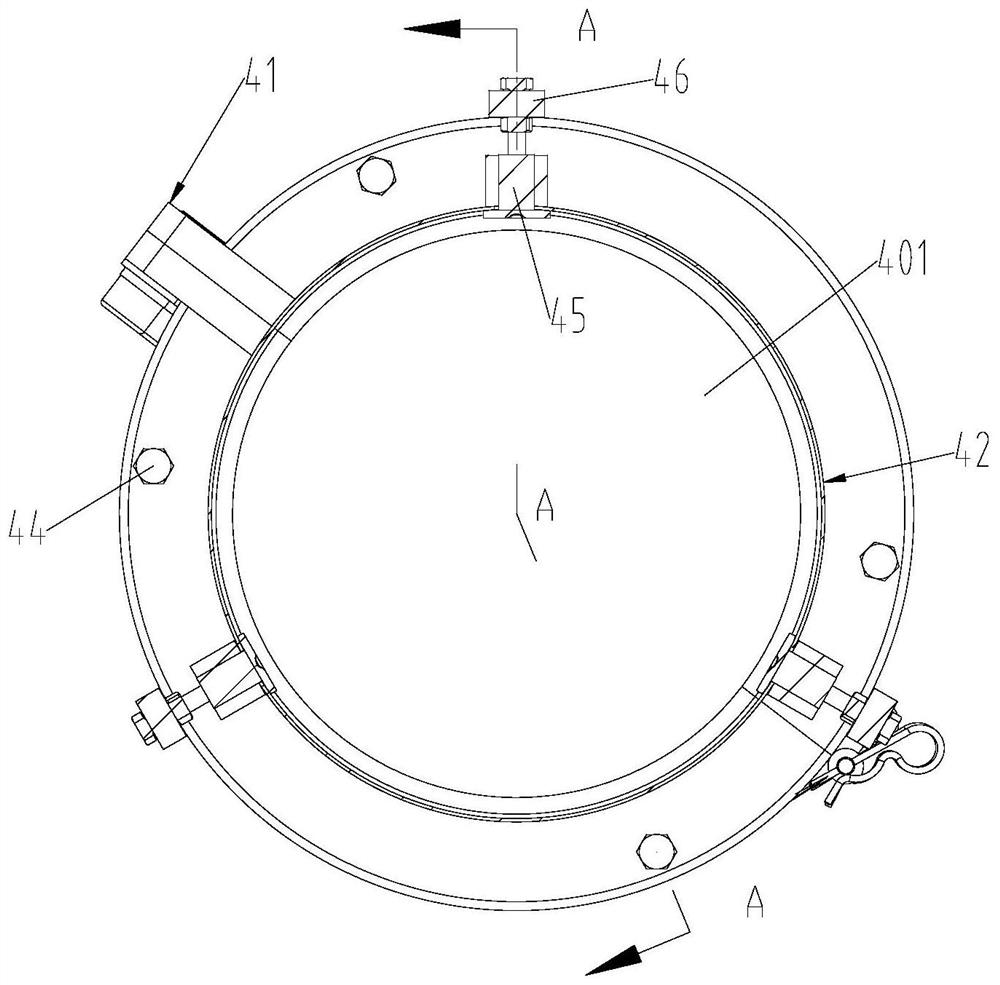

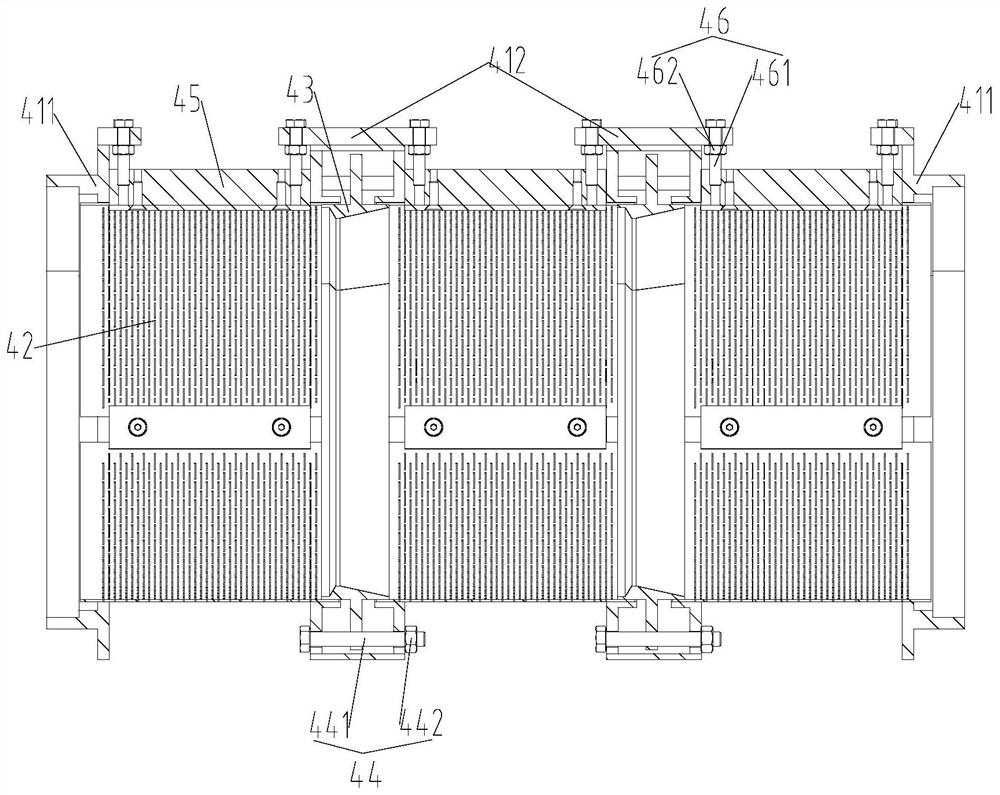

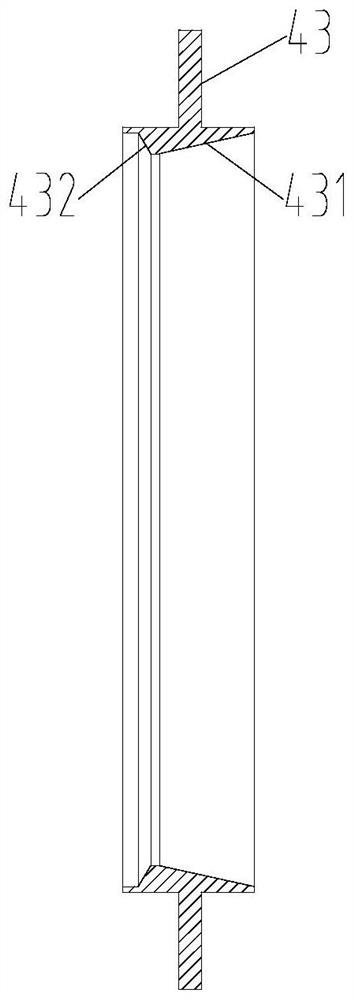

[0027] refer to figure 1 and figure 2 , the preferred embodiment of the present invention provides a novel rice milling chamber, comprising: a mounting frame assembly 41 connected to the rice mill frame, the mounting frame assembly 41 is provided with a plurality of hollow cylindrical sieve tubes 42 , and a plurality of ring-shaped adjustment rings 43, a plurality of sieve cylinders 42 are arranged at intervals along the flow direction of rice grains, and each adjustment ring 43 is arranged between every adjacent two sieve cylinders 42, so that the plurality of sieve cylinders 42 The inner passage and the inner passages of the plurality of adjustment rings 43 are connected to form a rice milling passage 401 extending along the flow direction of rice grains. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com