Quick assembling and wiring device for cable box

A technology of wiring device and cable box, which is applied to the parts, coupling device, connection and other directions of the connection device, can solve the problems of error-prone, troublesome wiring of the cable box, and disorderly distribution of lines, and achieves fast installation and fixation, guarantees stability, Easy to remove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

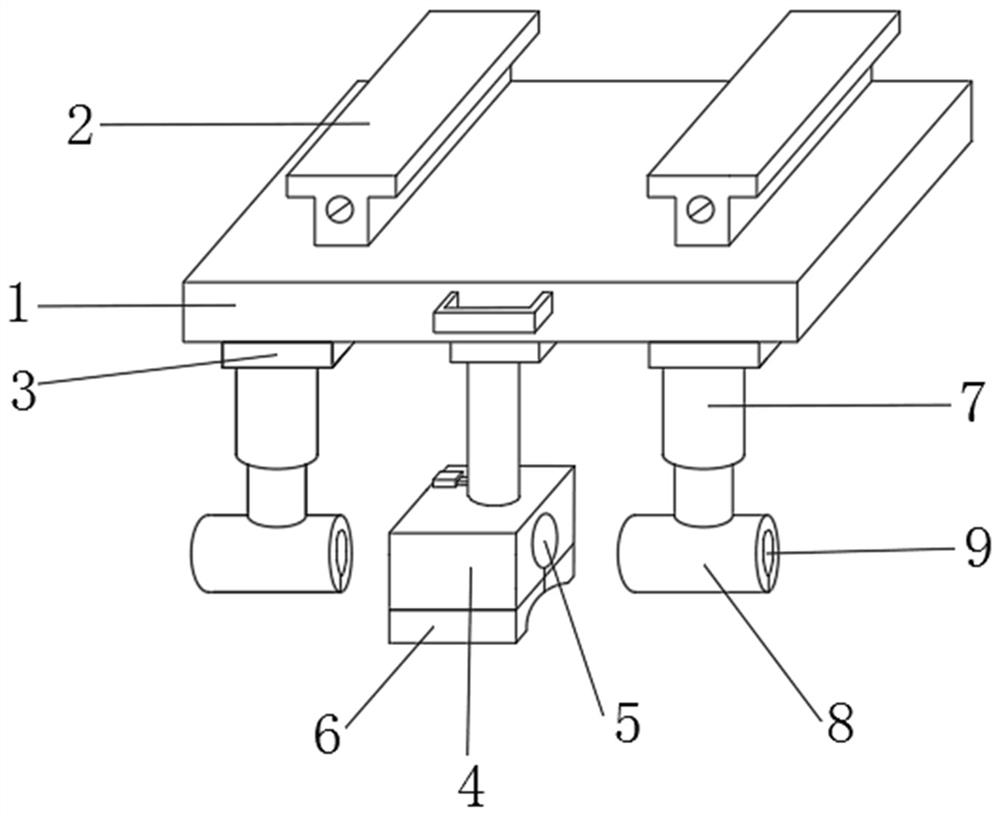

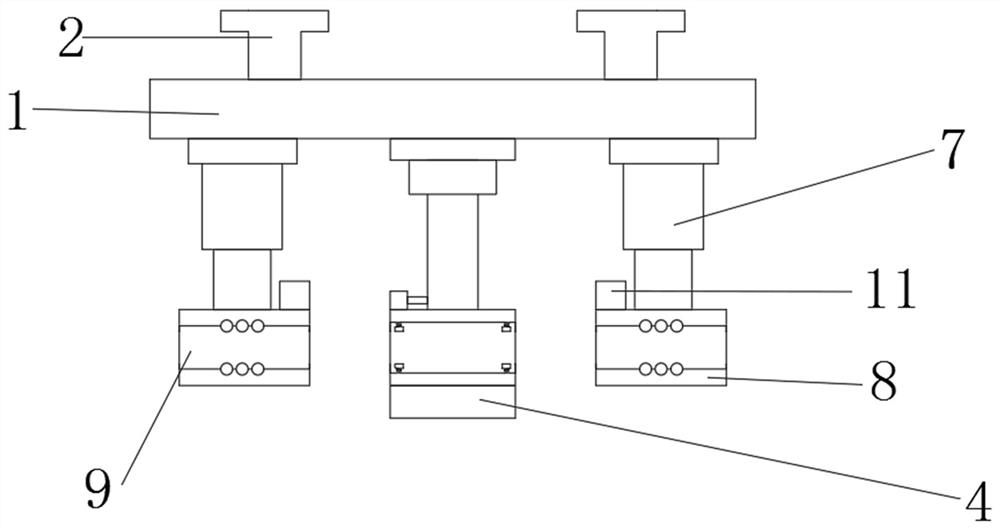

[0029] In this implementation, it is mainly used to introduce the use process of the cable box quick assembly wiring device during wiring.

[0030] like Figure 1-5 As shown, a cable box quick assembly wiring device includes a cable box connecting plate 1, a cable delivery mechanism 3, a cable wiring manipulator 4, and a wiring board 14, and the cable delivery mechanism 3 and the cable wiring manipulator 4 are all arranged on the cable box connection At the bottom of the plate 1, the cable delivery mechanism 3 is symmetrically arranged on the left and right sides of the cable connection manipulator 4, the wiring board 14 is arranged below the cable connection manipulator 4, and the cable box connection plate 1, the cable delivery mechanism 3, and the cable connection manipulator 4. The wiring boards 14 are all arranged inside the cable box 17, the top of the cable box 17 is provided with a mounting plate 16, the top of the cable box connecting plate 1 is fixedly connected with...

Embodiment 2

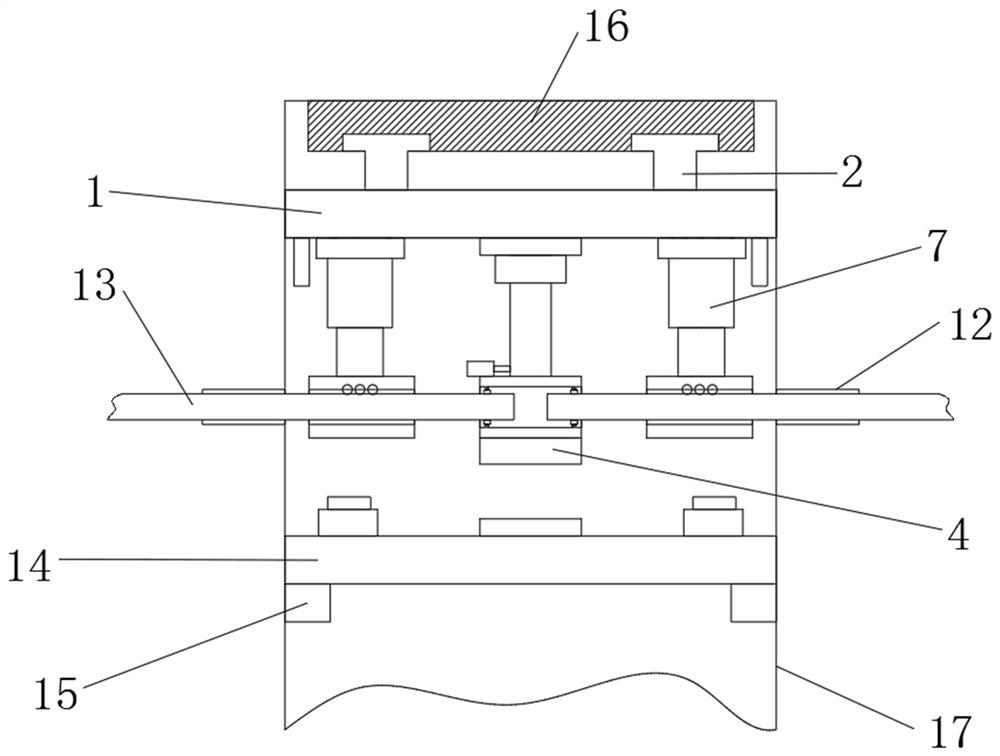

[0045] In this implementation, the use process of the quick assembly wiring device for the cable box is mainly introduced when the cable is crimped and fixed after the wiring is completed.

[0046] like Figure 1-4 as well as Image 6 As shown, a cable box quick assembly wiring device includes a cable box connecting plate 1, a cable delivery mechanism 3, a cable wiring manipulator 4, and a wiring board 14, and the cable delivery mechanism 3 and the cable wiring manipulator 4 are all arranged on the cable box connection At the bottom of the plate 1, the cable delivery mechanism 3 is symmetrically arranged on the left and right sides of the cable connection manipulator 4, the wiring board 14 is arranged below the cable connection manipulator 4, and the cable box connection plate 1, the cable delivery mechanism 3, and the cable connection manipulator 4. The wiring boards 14 are all arranged inside the cable box 17, the top of the cable box 17 is provided with a mounting plate 16...

Embodiment 3

[0059] In this embodiment, it is mainly used to introduce the disassembly and installation process of the cable box quick assembly wiring device on the cable box 17 .

[0060] Wherein, the wiring board 14 is arranged in conjunction with the quick assembly wiring device of the cable box, and the wiring board 14 is used in conjunction with the quick assembly wiring device of the cable box.

[0061] Inside the cable box 17 is provided with a wiring board support block 15, the wiring board 14 is slidably connected to the top of the wiring board support block 15, and the wiring board 14 and the wiring board support block 15 are arranged in groups, and can be viewed from above in a cable box. Set up multiple groups at the beginning, the cable box is quickly assembled and the wiring device is installed inside the cable box 17 through the slide rail 2 on the cable box connecting plate 1, and the wiring board 14 is installed on the uppermost wiring in turn. On the board support block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com