Automatic car loading machine for railway box car

A technology of railway box car and car loading machine, which is applied in the direction of lifting device, etc., which can solve the problems of difficult loading, limited space, and different specifications, and achieve the effects of reducing labor intensity, convenient operation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

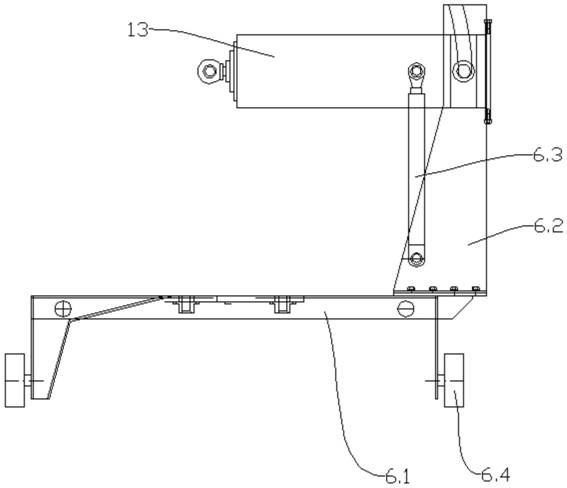

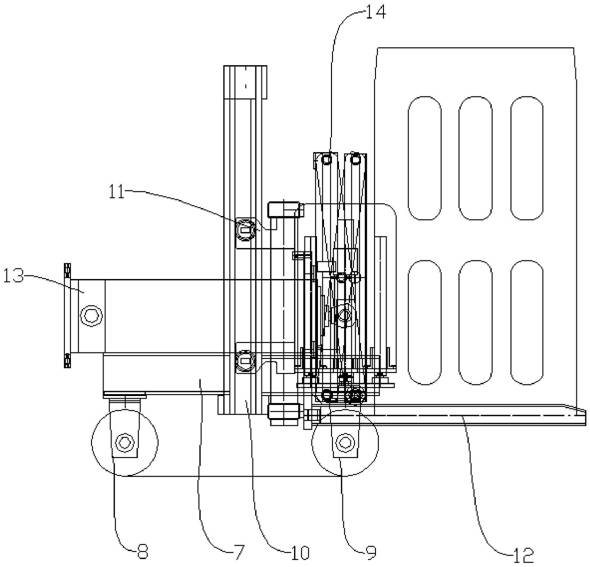

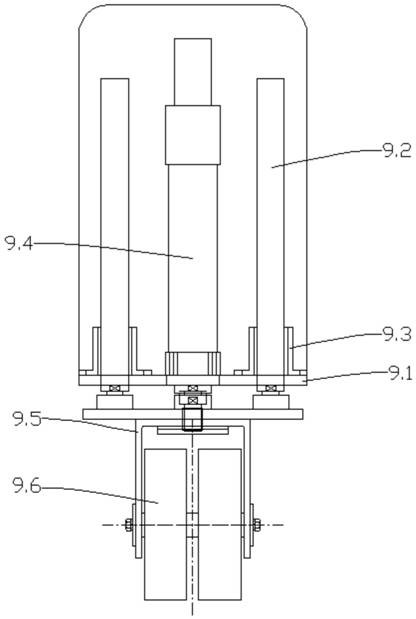

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0030] Such as figure 1 and figure 2 As shown, the present invention mainly includes a traversing vehicle plate 2 , which is rollingly connected to two parallel traversing ground rails 1 , and the traversing vehicle plate 2 can move laterally along the traversing ground rails 1 . When in use, two traversing ground rails 1 are arranged at the loading position on one side of the railway boxcar, and the traversing vehicle board 2 can move laterally relative to the railway boxcar through the two traversing ground rails 1 .

[0031] Such as image 3 As shown, the laterally moving vehicle plate 2 includes a vehicle plate body 2.1, the front and rear ends of the left side of the vehicle plate body 2.1 are respectively rotated and connected to the follower wheel 2.2, and the right and rear ends of the vehicle plate body 2.1 are respectively rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com