Circuit integrity detection system for detecting the integrity of a sensing wire in electrically heated textiles

A technology for sensing wires, textiles, applied in the field of electrically heated textile hot zone detectors, which can solve problems such as downtime and blocking products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

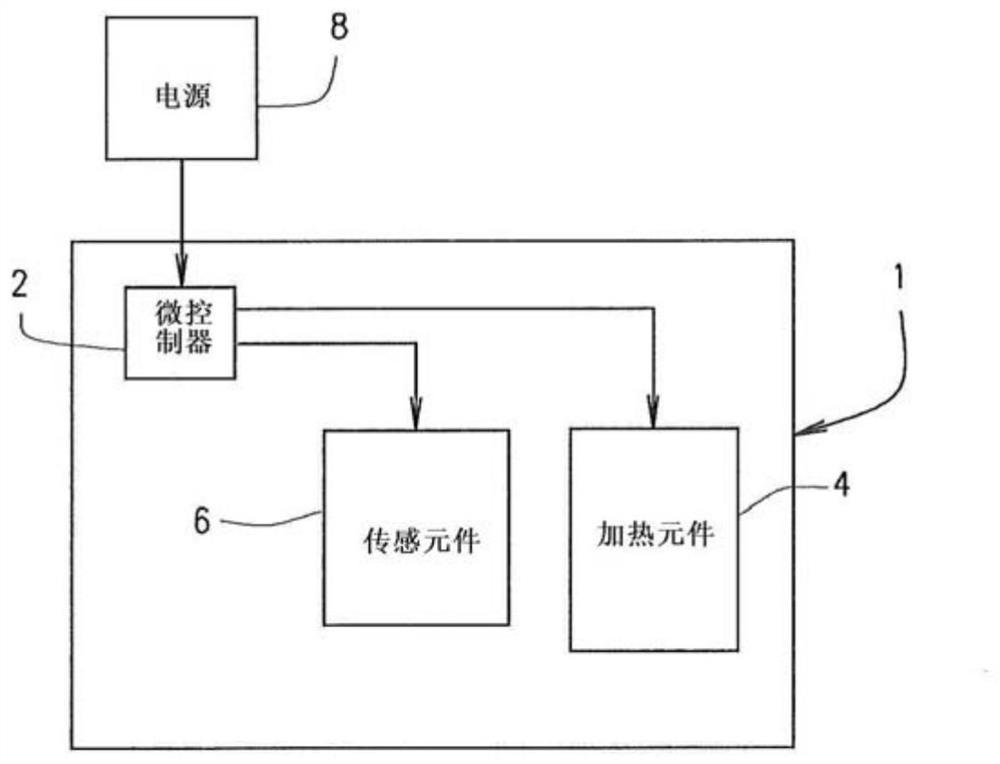

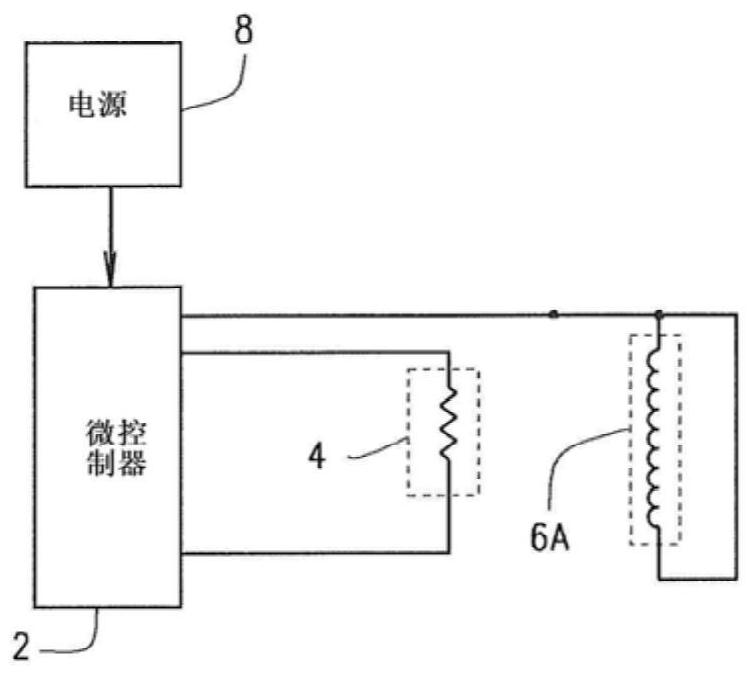

[0027] Referring now to the drawings, and in particular to figure 1 , showing a block diagram of a prior art electrically heated textile, such as a heating pad 1 . The heating mat 1 includes a heating mat controller 2 , which may include a microprocessor or microcontroller, for controlling the operation of the heating mat 1 . The microcontroller 2 is in electrical communication with the heating element 4 and supplies the heating element 4 with electrical energy to heat the heating mat 1 . Alternatively, the microcontroller 2 may be located outside the heating mat. Microcontroller 2 is also in electrical communication with sensing element 6 . The sensing element 6 is a safety feature designed for detecting hot spots in the heating mat 1 . Upon detection of a hot spot, the microcontroller 2 generally interrupts or reduces the electrical power supplied to the heating element 4 until the hot spot no longer occurs. The power supply 8 is generally electrically connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com