Whole-layer unstacker

A technology of unstacking machine and rack, which is applied in the direction of unstacking of objects, conveyor objects, stacking of objects, etc., which can solve the problems of different directions of goods, inability to process in large quantities, and difficulty in disassembling the stacks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

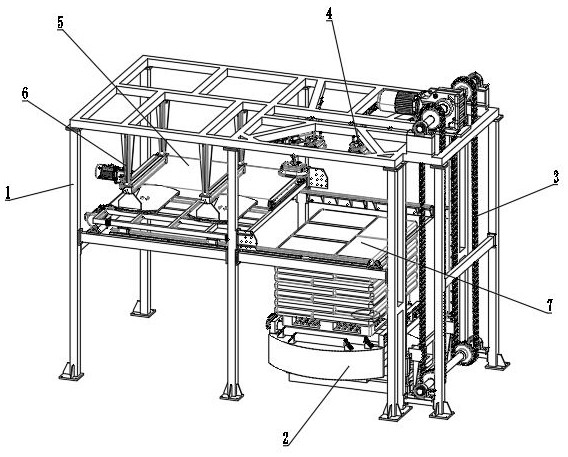

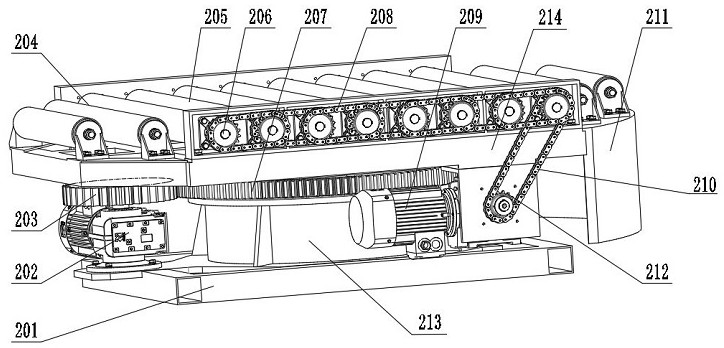

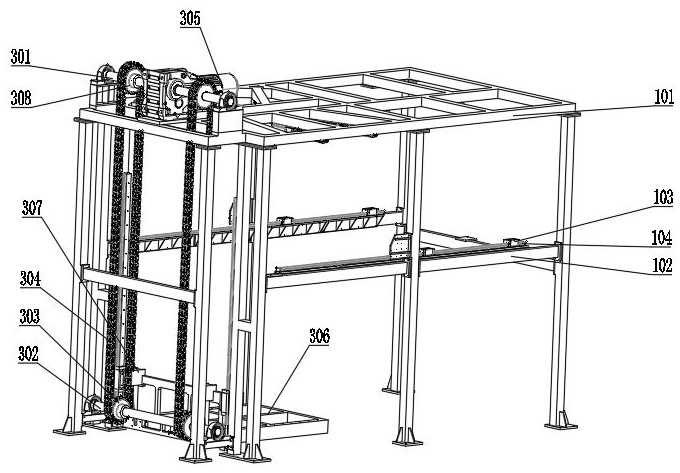

[0037] Such as figure 1 , 3 As shown, a full-layer destacker described in this embodiment includes a frame 1; the frame 1 is a double-layer structure, the upper layer is the first top plate 101, and the lower layer is a cross bar 102; the frame 1 A lifting mechanism 3 is vertically arranged at one end of the lifting mechanism 3, and a rotary conveying mechanism 2 for carrying the stack 7 is arranged on the lifting mechanism 3. The rotary conveying mechanism 2 has a steering function and a transportation function, and is used to transport the stack 7 to the rotary On the top of the conveying mechanism 2 and the adjustment of the overall direction of the cargo stack 7, above the rotary conveying mechanism 2 are provided with several suction cup mechanisms 4 fixed on the bottom of one side of the first top plate 101, and the suction cup mechanisms 4 are used for absorbing and rotating conveying For the goods on the mechanism 2, several push mechanisms 6 are provided at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com