Feeding bin

A silo and material point technology, applied in the field of feeding machinery and equipment, can solve the problem that two kinds of workpieces cannot be stored on the same rack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

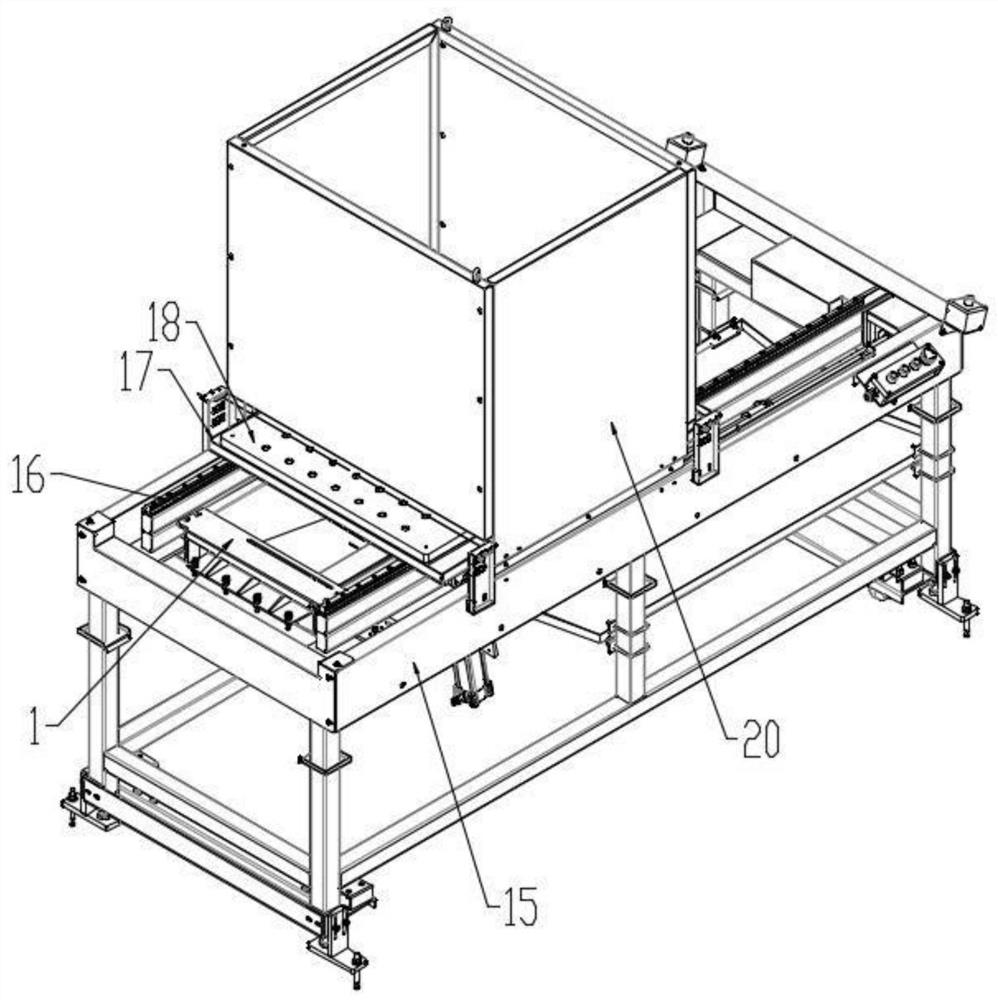

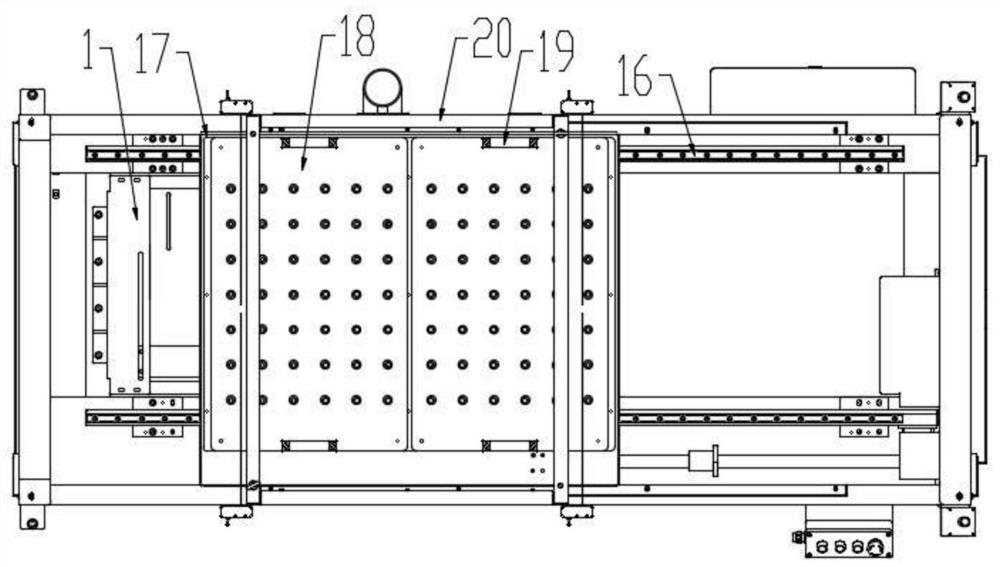

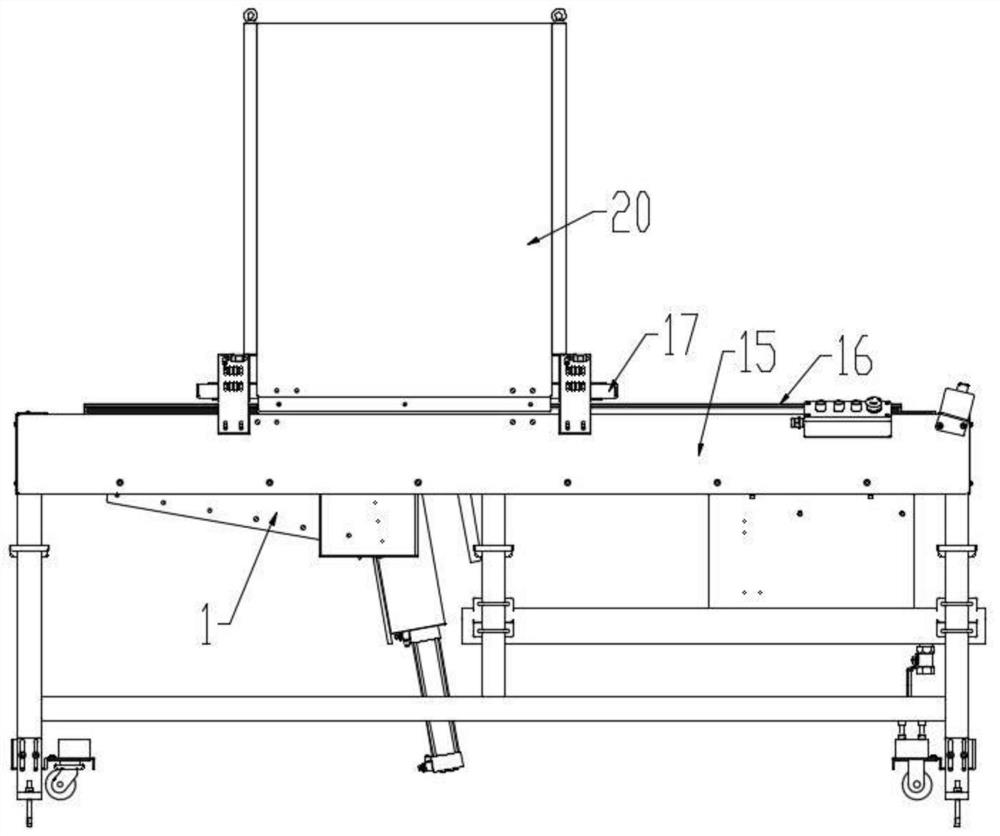

[0040] Such as Figure 1~3 Shown, a kind of feed bin, comprises frame 15, is provided with feed bin I1, feed bin II and protective cover 20 on frame 15. The silo I is used to store the shaft parts and realize the loading of the shaft parts. The silo II is used to store the disc-like parts and realize the loading of the disc-like parts. The silo II is arranged higher than the silo I1, so that the spatial positions of the silo II and the silo I are staggered up and down.

[0041] The bin I1 is located in the grabbing area on the left side of the frame 15, and the bin II slides between the grabbing area on the left side of the frame 15 and the loading area on the right side. When the bin II is located in the grabbing area, the manipulator can directly grab the discs in the bin II, but the bin I is blocked by the bin II, and the grabbing and loading cannot be realized. Slide the silo II to the loading area, the manipulator can directly grab the shafts in the silo I, and the sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com