Automatic welding structure for plastic products

An automatic welding and product technology, applied in the field of welding, can solve the problems of low welding efficiency, different heating conditions, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

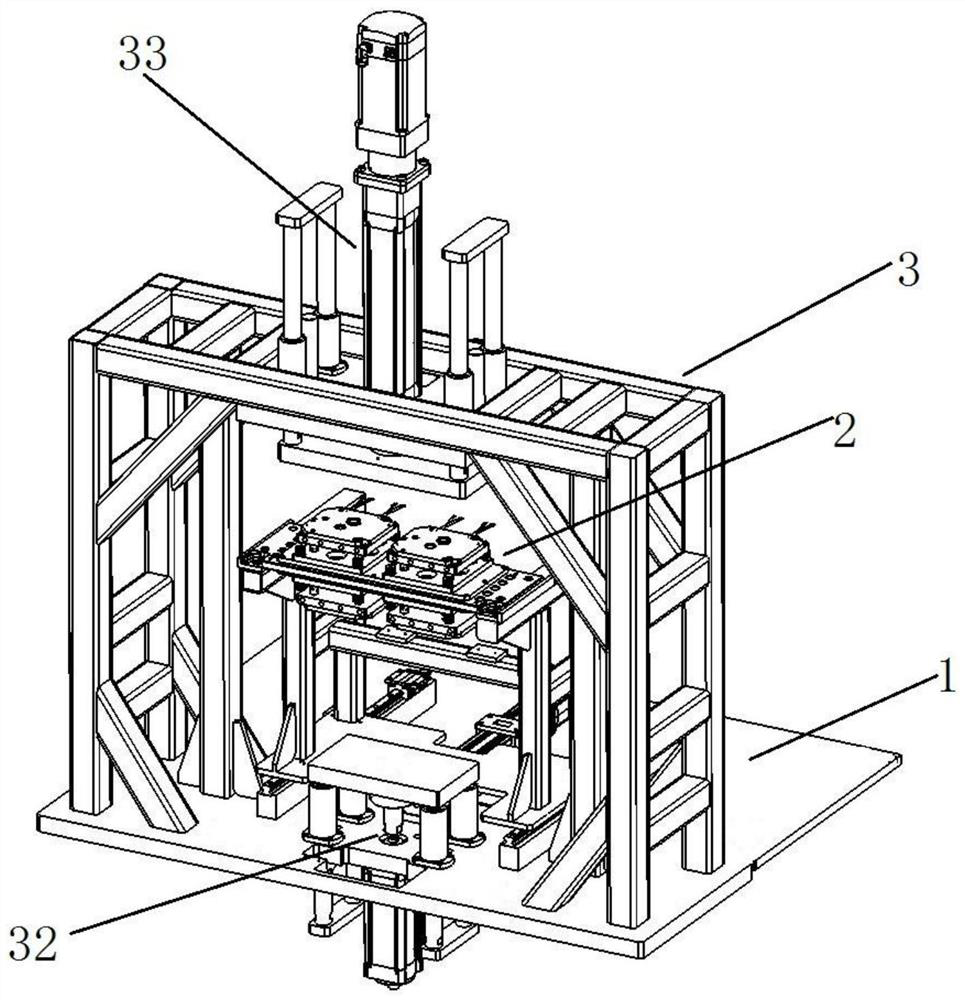

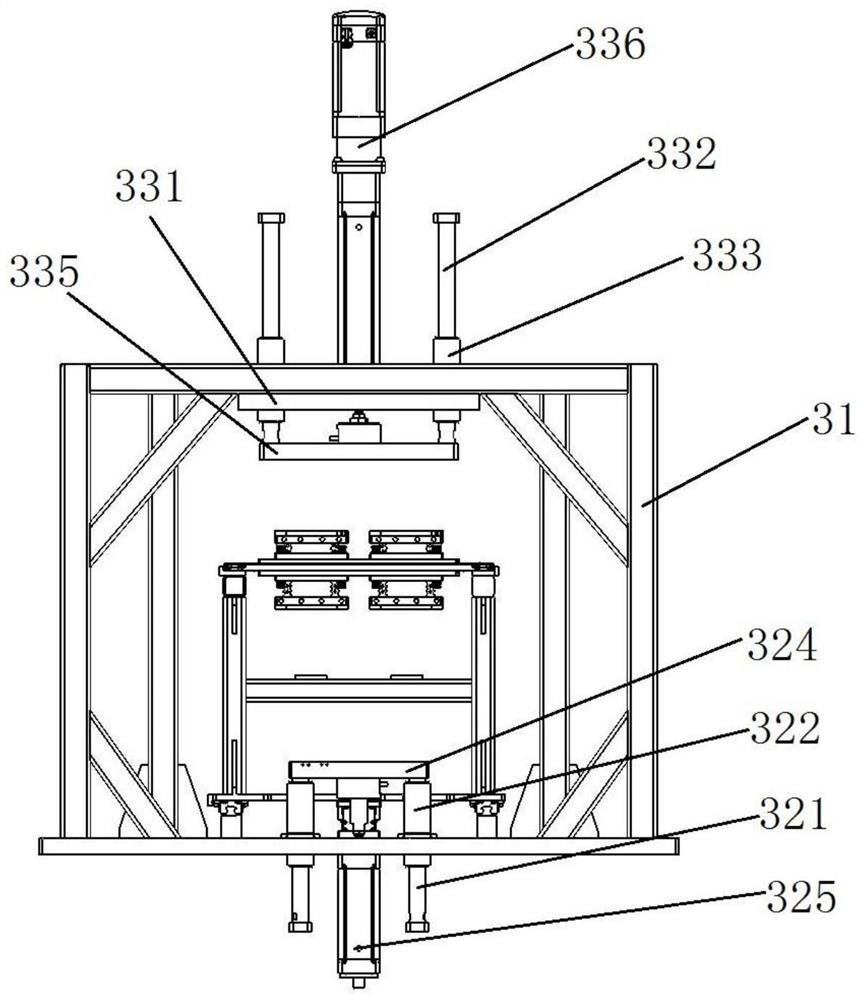

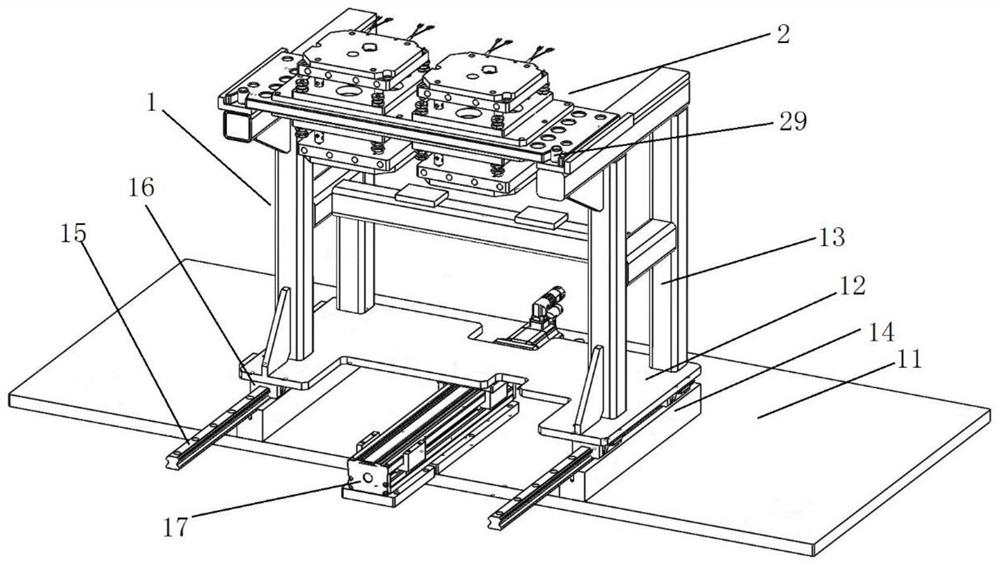

[0035] Such as Figure 1 to Figure 6 As shown, the plastic product automatic welding structure of the present invention is usually used for automatic welding of plastic products, and it mainly includes a support assembly 1, a thermal mold assembly 2, and a feeding assembly 3, etc.

[0036] The support assembly 1 mainly includes a base plate 11, a moving plate 12, a first frame body 13, a backing plate 14, a slide rail 15, a slide block 16 and a slide table cylinder 17, etc., and the base plate 11 is usually fixed on the machine table (the base plate 11 is rectangular The metal plate is made of stainless steel and can be fixed by screw fastening). Backing plate 14 has two, and they are fixed on the base plate 11 at intervals. The slide rail 15 is fixed on the backing plate 14 by means of screw fastening, and the slide block 16 is slidably inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com