A kind of high-brightness prism bonding film and preparation method thereof

A high-brightness, laminated film technology, applied in the field of optical films, can solve the problems of large brightness loss and low light transmittance of optical modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

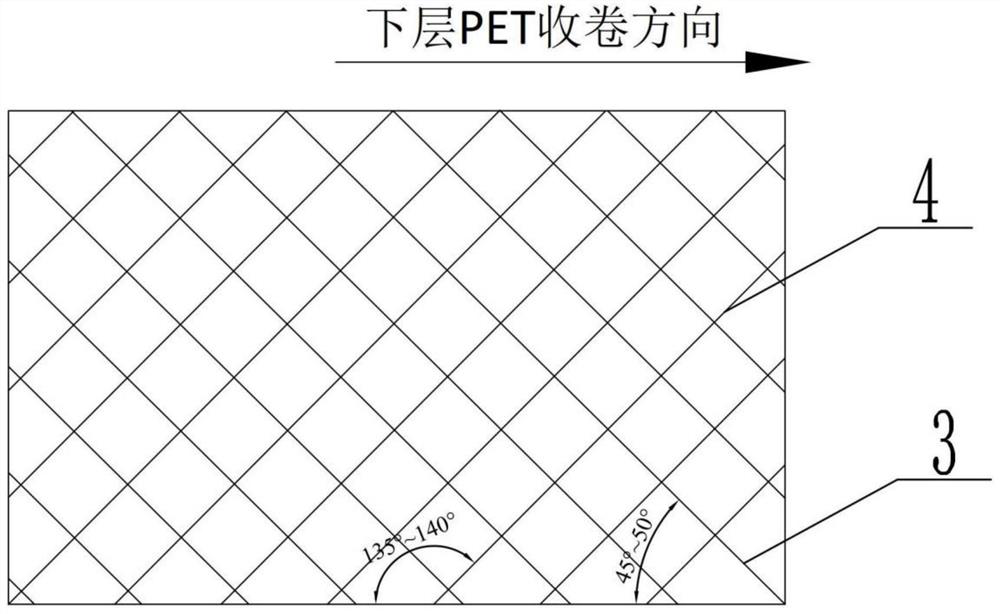

[0038] A high-brightness prism lamination film, from bottom to top, comprises a back coating layer 1, a PET layer 2, a first prism layer 3, a second prism layer 4, the first prism layer 3 and the second prism layer 4, the first prism layer 3 and the second prism layer Prisms are arranged on each layer 4 in an array, the apex angles of the prisms of the first prism layer 3 are inserted into the lower surface of the second prism layer 4, and the longitudinal extension direction of the prisms of the first prism layer 3 is the same as that of the second prism layer 3. The longitudinal extension direction of the prisms of the prism layer 4 is an included angle of 90°, the prism height of the first prism layer 3 is 20 μm, the height difference of each prism vertex of the first prism layer 3 is 0.5 μm, and the second prism The prism height of the layer 4 is 20 μm, the prisms of the second prism layer 4 are set at the same height, and the haze of the back coating layer 1 is 2%.

[003...

Embodiment 2

[0052] A high-brightness prism lamination film, from bottom to top, comprises a back coating layer 1, a PET layer 2, a first prism layer 3, a second prism layer 4, the first prism layer 3 and the second prism layer 4, the first prism layer 3 and the second prism layer Prisms are arranged on each layer 4 in an array, the apex angles of the prisms of the first prism layer 3 are inserted into the lower surface of the second prism layer 4, and the longitudinal extension direction of the prisms of the first prism layer 3 is the same as that of the second prism layer 3. The longitudinal extension direction of the prisms of the prism layer 4 is at an included angle of 90°, the prism height of the first prism layer 3 is 44 μm, the height difference of each prism vertex of the first prism layer 3 is 2 μm, and the second prism layer The prism height of 4 is 44 μm, the prisms of the second prism layer 4 are set at the same height, and the haze of the back coating layer 1 is 10%.

[0053]...

Embodiment 3

[0066] A high-brightness prism lamination film, from bottom to top, comprises a back coating layer 1, a PET layer 2, a first prism layer 3, a second prism layer 4, the first prism layer 3 and the second prism layer 4, the first prism layer 3 and the second prism layer Prisms are arranged on each layer 4 in an array, the apex angles of the prisms of the first prism layer 3 are inserted into the lower surface of the second prism layer 4, and the longitudinal extension direction of the prisms of the first prism layer 3 is the same as that of the second prism layer 3. The longitudinal extension direction of the prisms of the prism layer 4 is at an included angle of 90°, the prism height of the first prism layer 3 is 32 μm, the height difference of each prism vertex of the first prism layer 3 is 1.3 μm, and the second prism The prism height of the layer 4 is 32 μm, the prisms of the second prism layer 4 are set at the same height, and the haze of the back coating layer 1 is 6%.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com