Defect identifying and trimming mechanism for strip-column-shaped fruits and vegetables

A trimming mechanism and defect identification technology, applied in the fields of optical testing defect/defect, food science, measuring device, etc., can solve the problems of inability to trim fruits and vegetables, inability to separate fruits and vegetables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

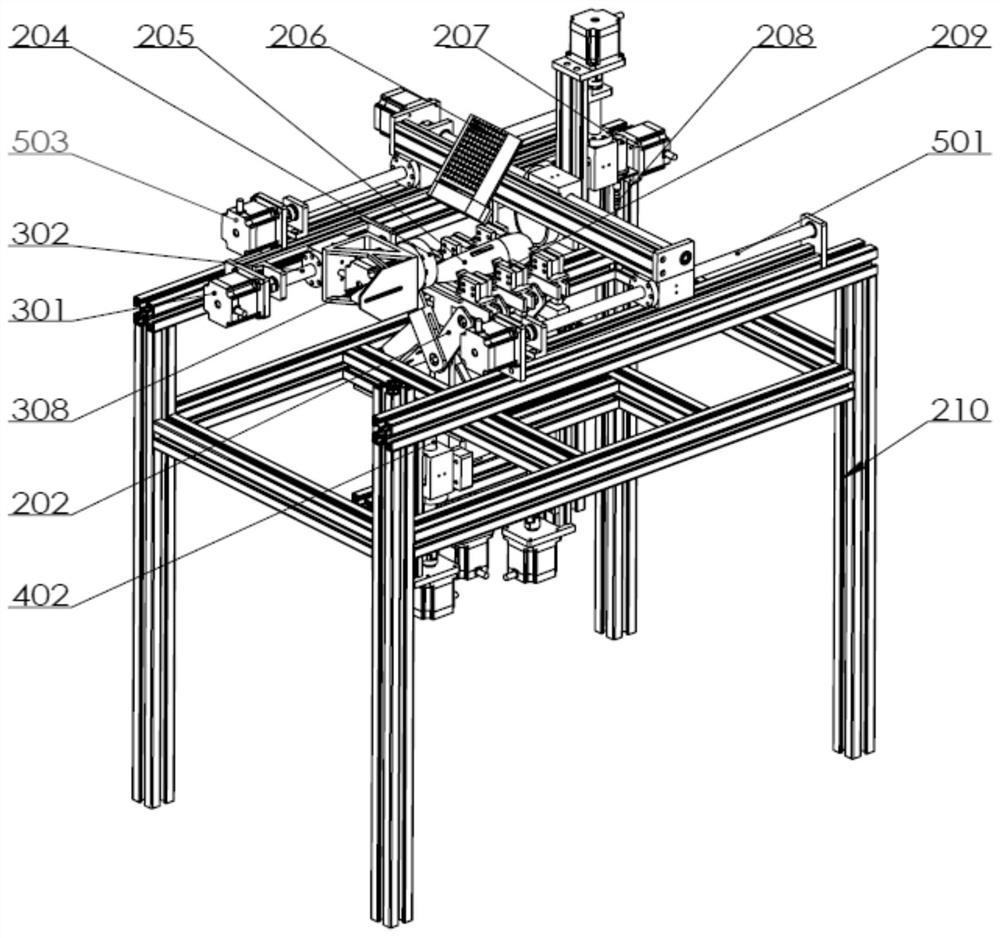

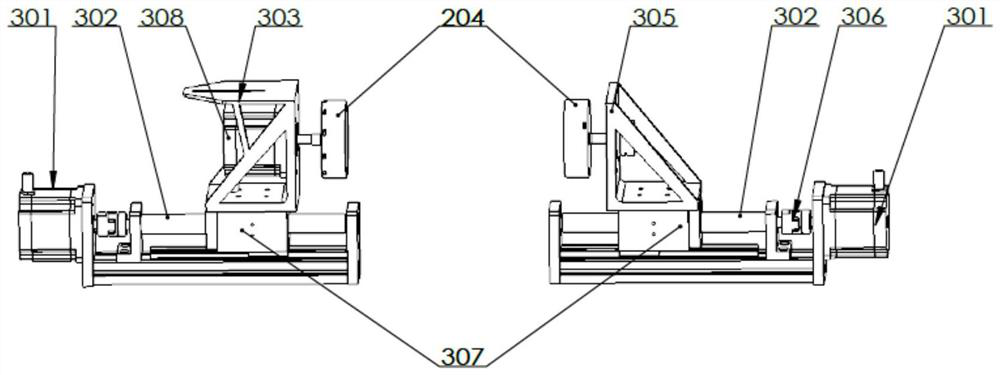

[0059] Example 1: Please refer to figure 1 , the columnar fruit and vegetable defect identification and trimming mechanism includes a frame 210, a positioning and rotating mechanism, a clamping mechanism, a trimming mechanism, a depth camera 206 and a controller;

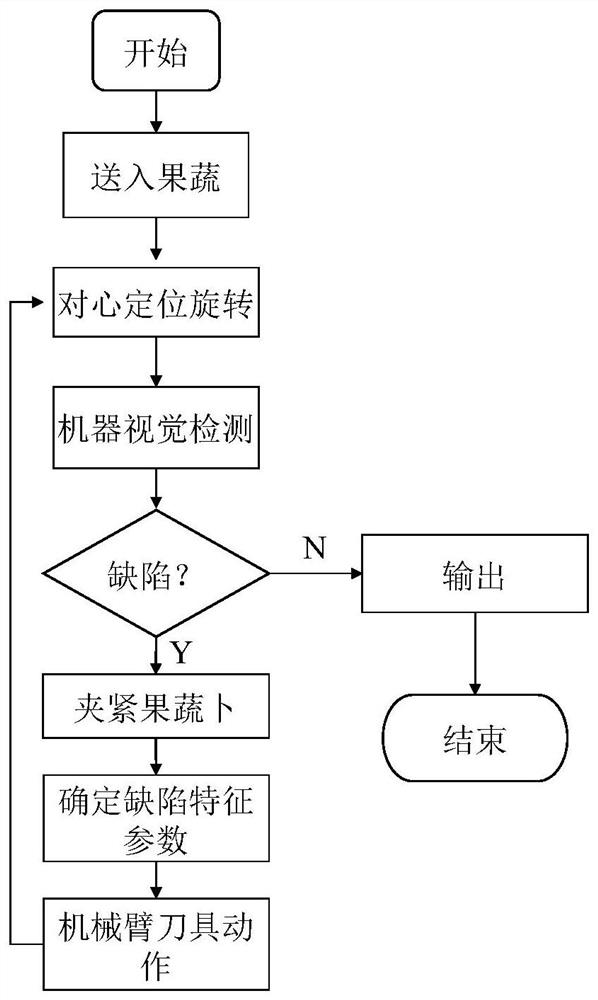

[0060] The columnar fruits and vegetables are put into the defect identification and trimming mechanism of the columnar fruits and vegetables. First, the columnar fruits and vegetables are centered and rotated. The depth camera 206 collects the 360-degree image of the columnar fruits and vegetables 205 and performs image processing and three-dimensional reconstruction to obtain the characteristic parameters of the defects. Then the clamping mechanism clamps the columnar fruits and vegetables 205, and finally guides the action of the mechanical arm to drive the rotary cutter 208 to remove defects according to the planned path. After a week of defect removal is completed, the depth camera 206 rotates again with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com