Fast forward device with hydraulic fertilizer pushing mechanism

A hydraulic and hydraulic valve technology, applied in the field of fast-forward devices, can solve problems such as affecting the effect of soil fertilization, large gaps in the fertilizer box, uneven soil fertilization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

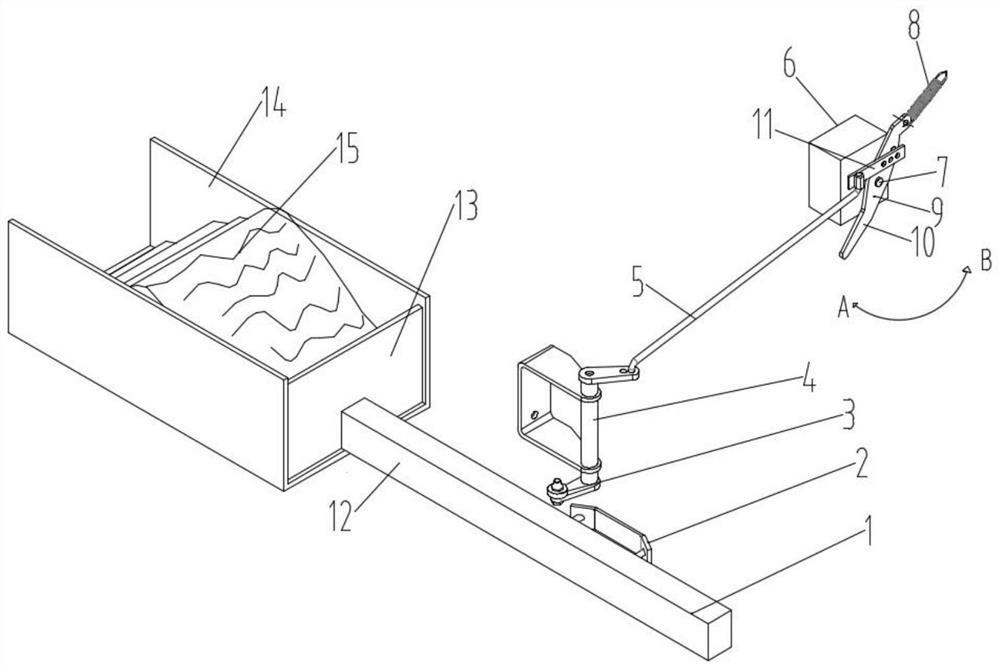

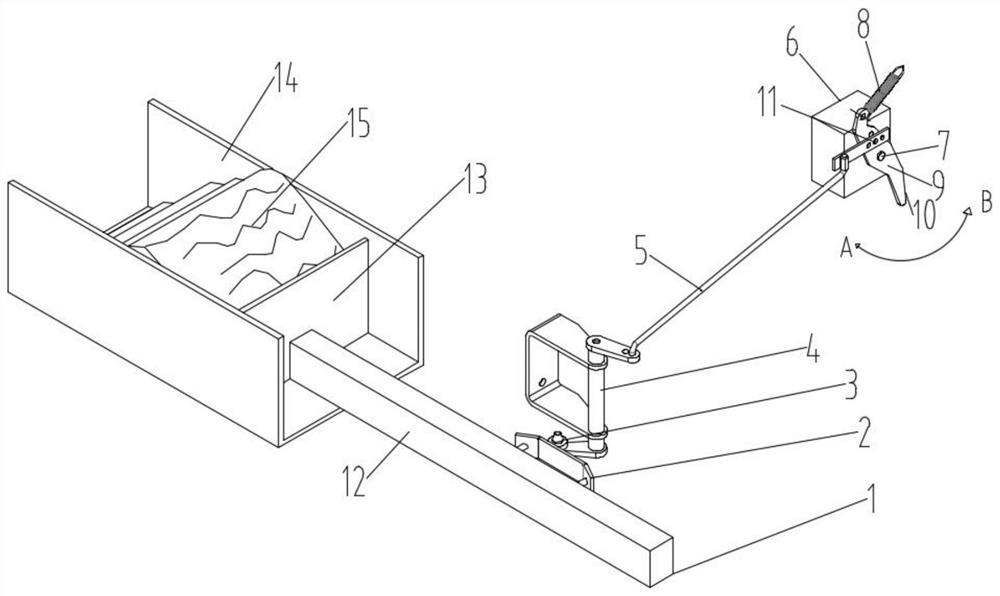

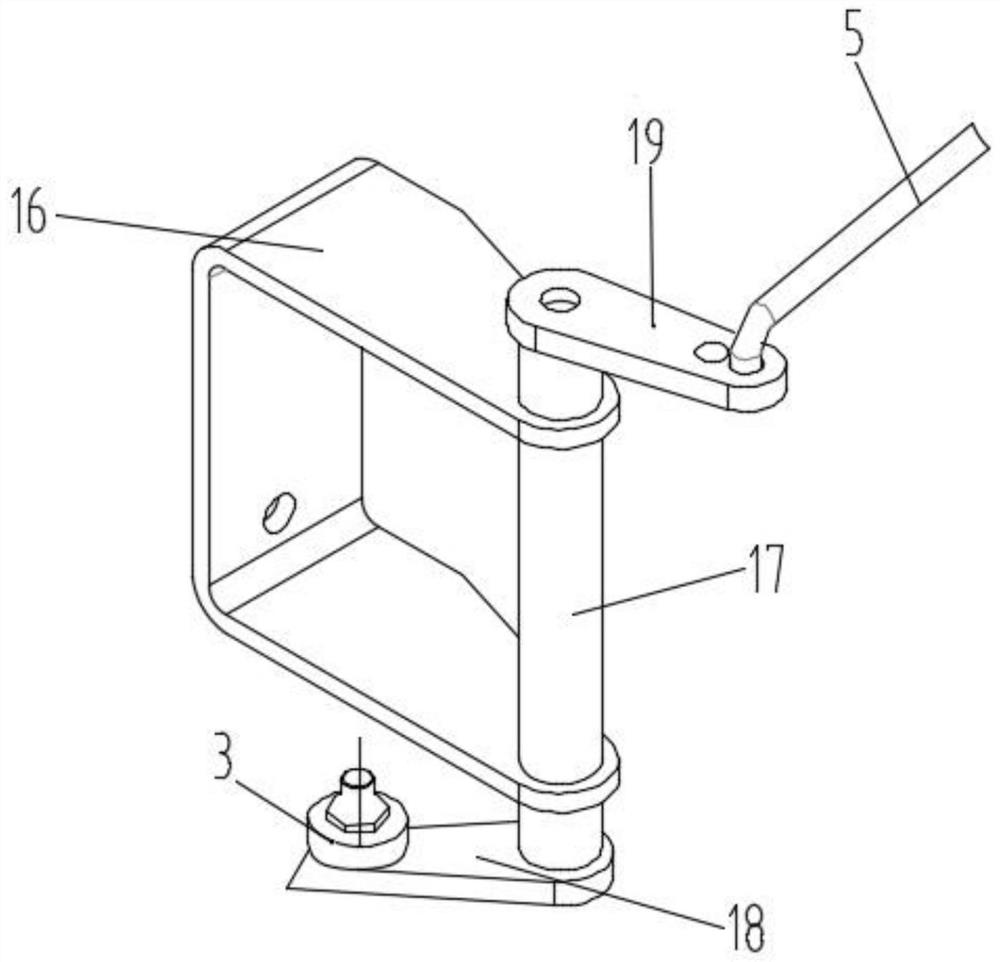

[0022] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, a fast-forward device of a hydraulic fertilizer pushing mechanism in this embodiment, including a fertilizer pushing mechanism 1, a guide rail 2, a pulley 3, a guiding actuator 4, a pull rod 5, a hydraulic valve body 6, and a hydraulic valve rotor 7 And the executive rod 9, the guide rail 2 is fixedly installed on the fat pushing mechanism 1, the pulley 3 is rotatably installed on the guide actuator 4, the other end of the guide actuator 4 is equipped with a pull rod 5, and the other end of the pull rod 5 is fixedly connected with the actuator rod 9 , the hydraulic valve body 6 is equipped with a hydraulic valve rotating core 7, the executive rod 9 is fixedly installed on the hydraulic valve rotating core 7, the fertilizer pushing mechanism 1 is fixedly connected with the hydraulic mechanism, the hydraulic mechanism is an existing hydraulic push rod, and the hydraulic valve body 6. Co...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination Figure 1-Figure 3 Describe this embodiment, a fast-forward device of a hydraulic fat pushing mechanism in this embodiment, one end of the actuator rod 9 is fixedly connected to a spring 8, the other end of the spring 8 is fixedly placed, and is fixedly installed at the end of the actuator rod 9 There is a spring 8, and the other end of the spring 8 is fixed. When the fertilizer pushing mechanism 1 continues to push forward to the middle part, there is no longer a large gap in the fertilizer box 14, the guide rail 2 and the pulley 3 are no longer in contact, and the spring 8 shrinks and pulls to execute Rod 9 restores the actuator rod 9 to its original position, and the actuator rod 9 drives the hydraulic valve core 7 to return to the original position. The hydraulic valve body 6 controls the hydraulic mechanism to restore the initial flow rate, so that the fertilizer pushing mechanism 1 advances at a constant speed according...

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 1-Figure 3 Describe this embodiment, a fast-forward device of a hydraulic fat pushing mechanism in this embodiment, the actuator rod 9 has a pointer 10, and the actuator rod 9 is processed with a pointer 10, and the hydraulic valve body can be understood according to the direction of the pointer 10. 6. Control the flow of the hydraulic mechanism. When the pointer 10 points to the A direction, the hydraulic mechanism drives the fat pushing mechanism 1 to advance at a constant speed. When the pointer 10 points to the B direction, the hydraulic valve body 6 controls the hydraulic mechanism to drive the fat pushing mechanism 1 to accelerate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com