Automatic calibration control system and method for seeding quantity and fertilizing quantity of precision seeder

An automatic calibration and control system technology, applied in the direction of control system, general control system, control/adjustment system, etc., can solve problems such as low efficiency, cumbersome work, complicated operation, etc., to increase equipment cost, simple and convenient operation, and equipment modification small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

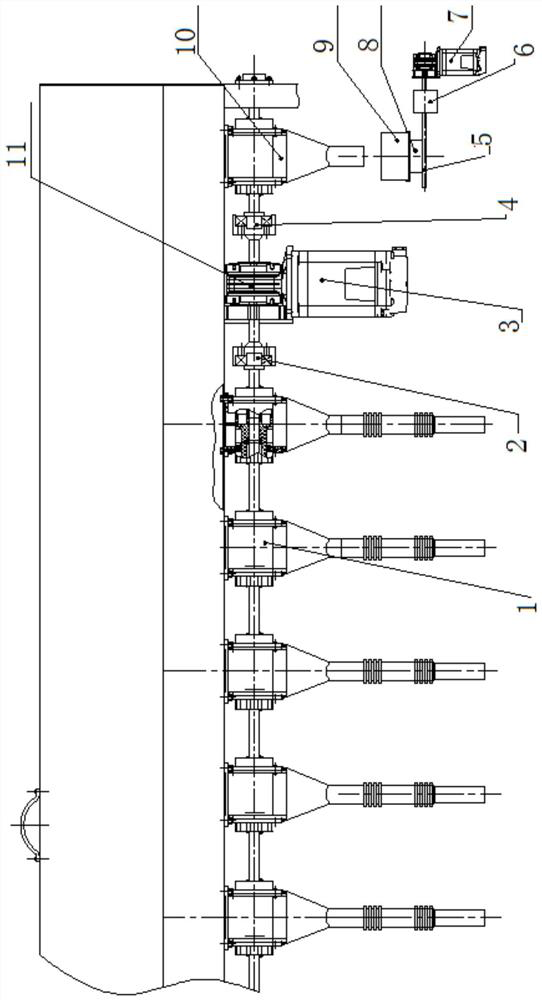

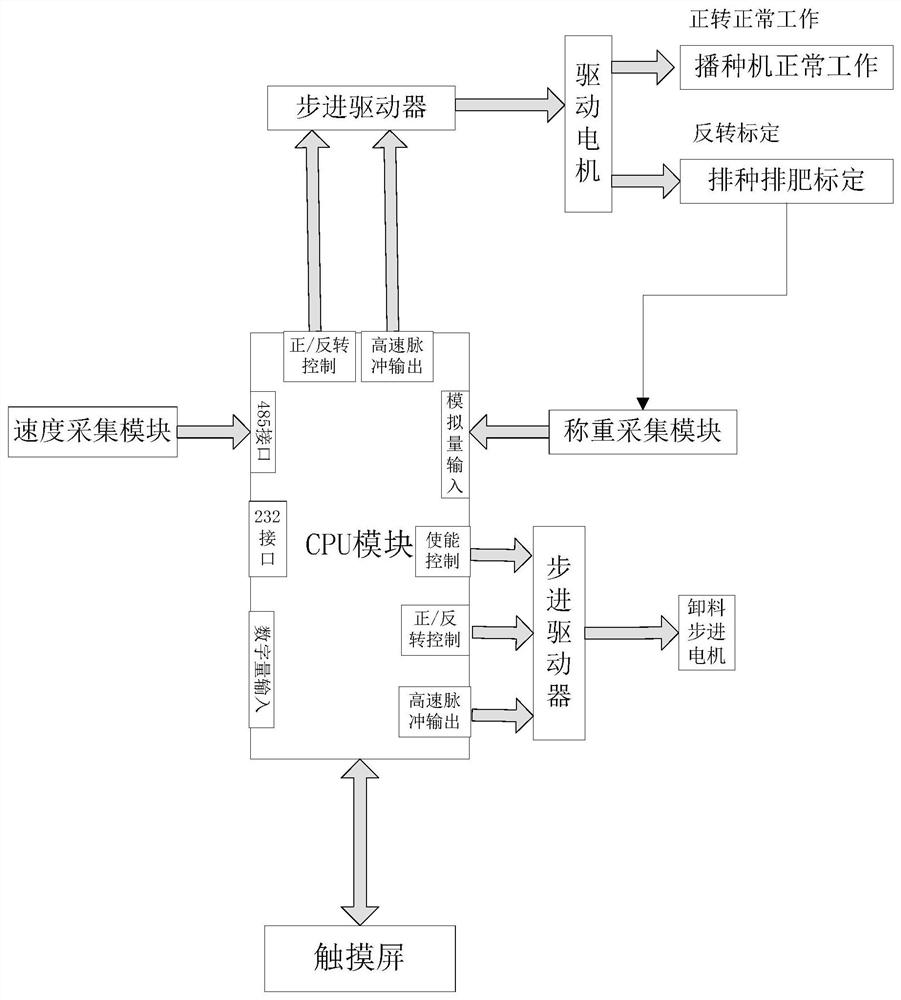

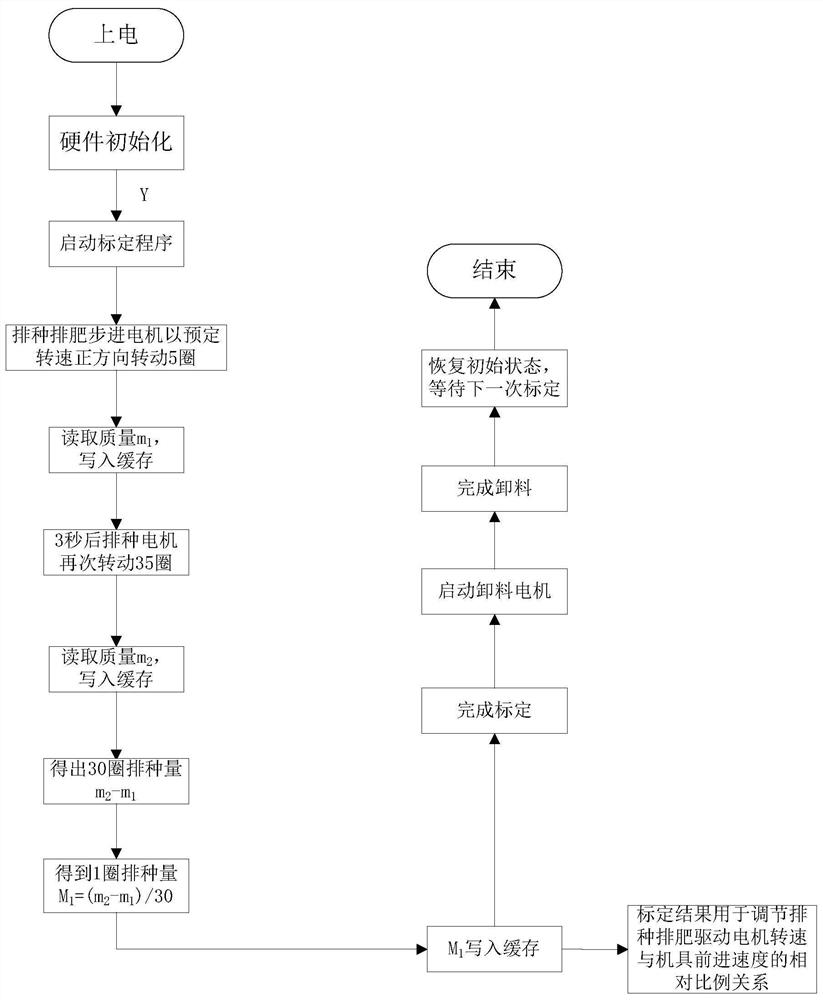

[0038] see Figure 1-3 , an automatic calibration control system for seeding rate and fertilization rate of a precision seeder, comprising: a power part that can rotate forward and reverse has a double-sided power output end; 1 connection, and the other side is connected with the seeding and fertilization component 10 for calibration through the second transmission one-way bearing 4; the locking direction of the first transmission one-way bearing 2 and the second transmission one-way bearing 4 are opposite, and they can rotate freely Direction is opposite; Described sorting and fertilizing parts 10 belows are provided with weighing acquisition module; Described power unit has speed acquisition module, sowing stepper driver; CPU module is as the control center of whole control system, respectively with speed acquisition module, Seeding stepper driver, weighing acquisition module signal connection.

[0039] see figure 1 , the power component is the drive motor 3 .

[0040] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com