Waste ABS plastic crushing and paint removing machine

An ABS plastic and paint stripping technology, which is applied in the direction of plastic recycling and recycling technology, can solve the problems of slow paint stripping efficiency, difficult paint removal, and affecting the paint stripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

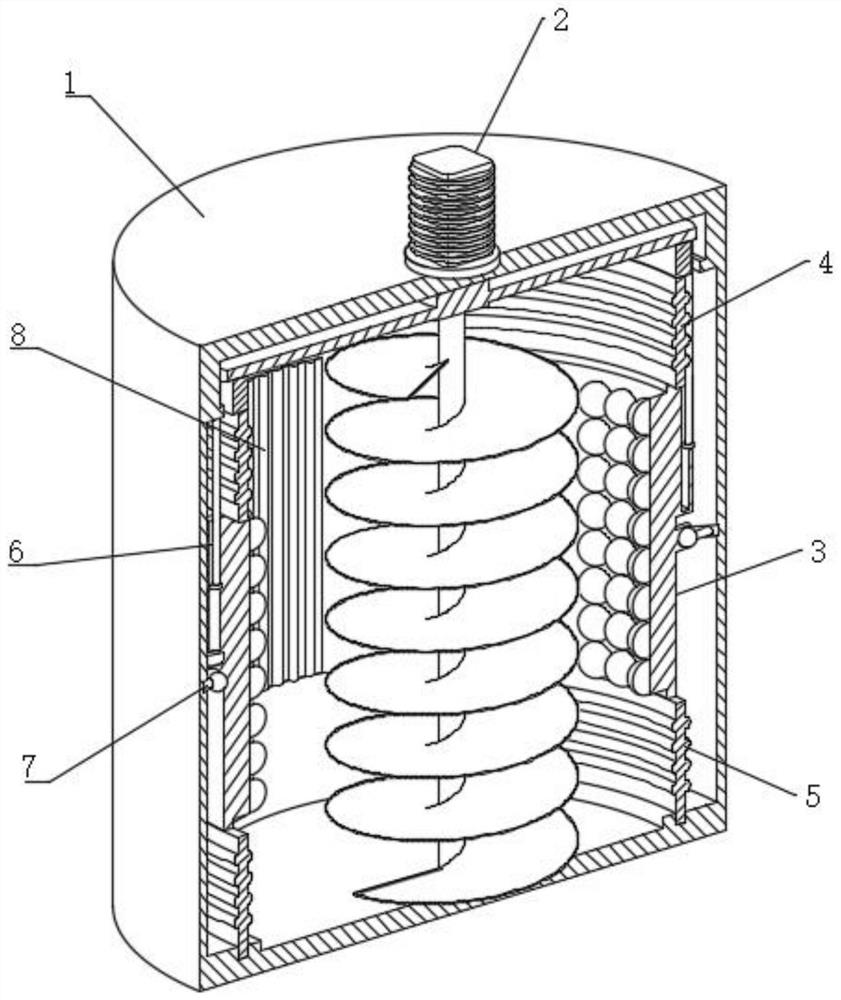

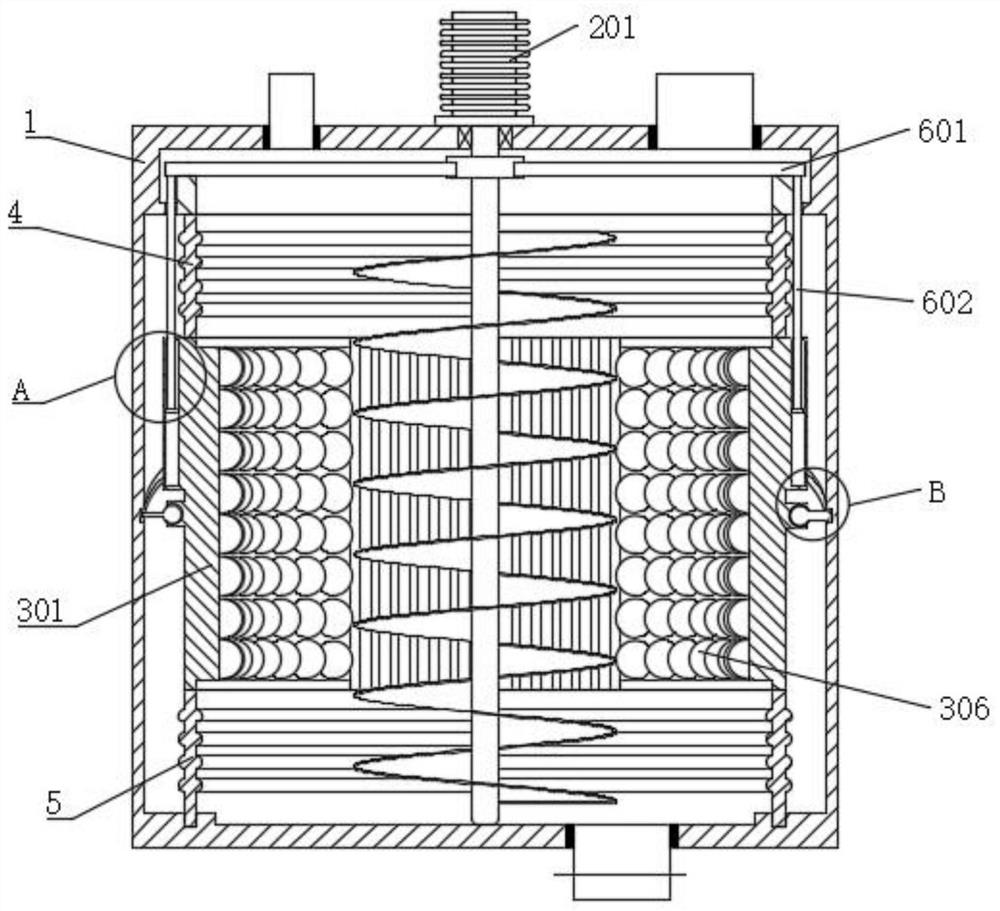

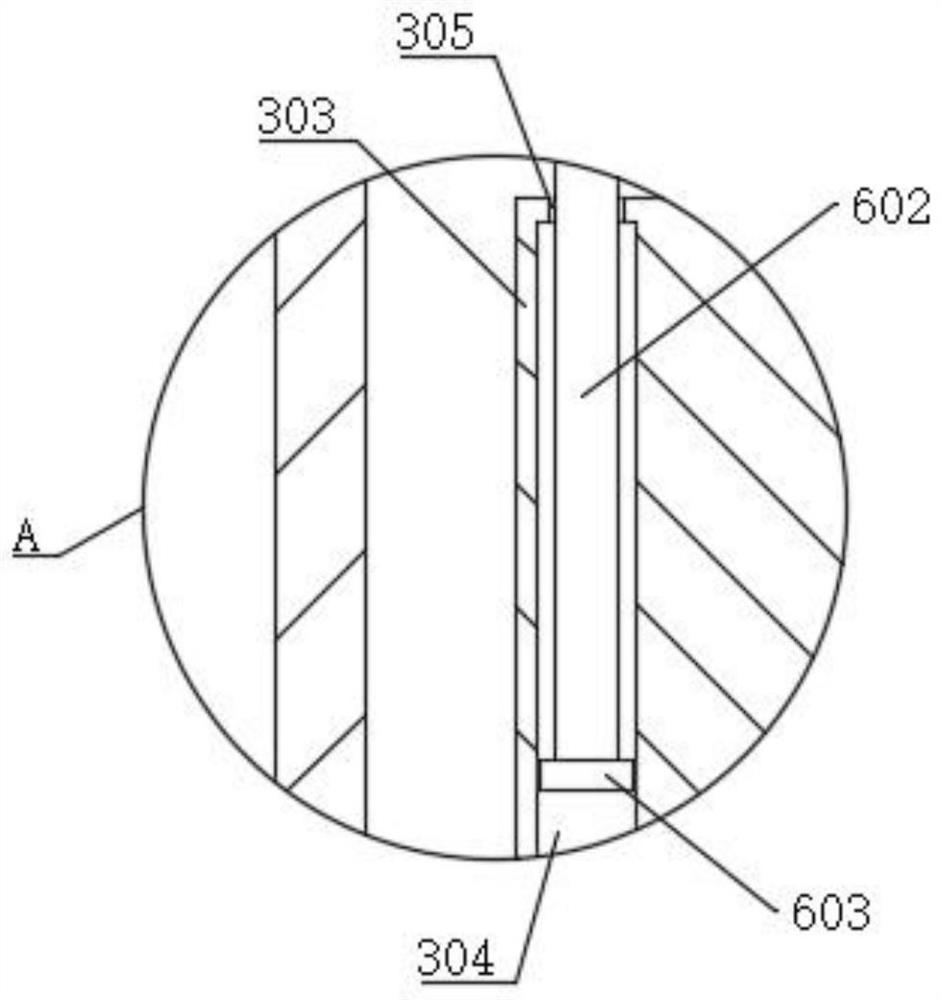

[0050] see Figure 1-9 , a waste ABS plastic crushing paint remover, comprising a body 1, a stirring assembly 2 is connected to the body 1, a linkage assembly 6 is connected to the upper end of the stirring assembly 2, a kneading assembly 3 is connected to the lower end of the linkage assembly 6, and the kneading assembly 3 is connected to the stirring assembly Components 2 are matched, and the inner wall of the body 1 is provided with an inclined annular groove 101, and a pair of sliding rods 7 matching the kneading component 3 are slidably connected in the annular groove 101; please refer to Figure 9 , the stirring assembly 2 includes a motor 201, the motor 201 is a prior art, those skilled in the art can select a suitable type of motor 201 according to actual needs, for example: the model is Y90S-2, the upper end of the body 1 is fixedly installed with a motor 201, the motor 201 The lower end is connected with a rotating rod 202 , the lower end of the rotating rod 202 exte...

Embodiment 2

[0058] see Figure 1-9 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to figure 1 The body 1 is provided with a heating layer and an insulating layer, the heating layer is made of resistance wire and ceramic material, the insulating layer is made of polyurethane material, and the insulating layer is located outside the heating layer. The efficiency of paint removal is further improved by means of heating, the insulation layer can effectively reduce the loss of heat, effectively improve the utilization rate of heat energy, reduce the waste of resources, and improve the environmental protection of paint removal work.

Embodiment 3

[0060] see Figure 1-9 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 3 and embodiment 1 is: a kind of paint stripping method of waste ABS plastic pulverizing paint stripper, concrete steps are as follows:

[0061] S1. Add a plastic paint remover to the body 1, and heat and keep it warm;

[0062] S2. Put the crushed waste ABS plastic into the body 1;

[0063] S3. Start the motor 201, so that the rotating rod 202 drives the screw block 203 and the linkage rod 601 to rotate at the same time, and removes the paint from the waste ABS plastic;

[0064] S4. The linkage rod 601 drives the kneading block 301 to rotate through the support rod 602, and the kneading block 301 moves up and down while rotating under the restriction of the slide bar 7 and the annular groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com