Thrower with large throwing area

A throwing machine, a technology with a large area, applied in fish farming, application, climate change adaptation and other directions, can solve the problems of insufficient dissolved oxygen and insufficient dissolved oxygen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

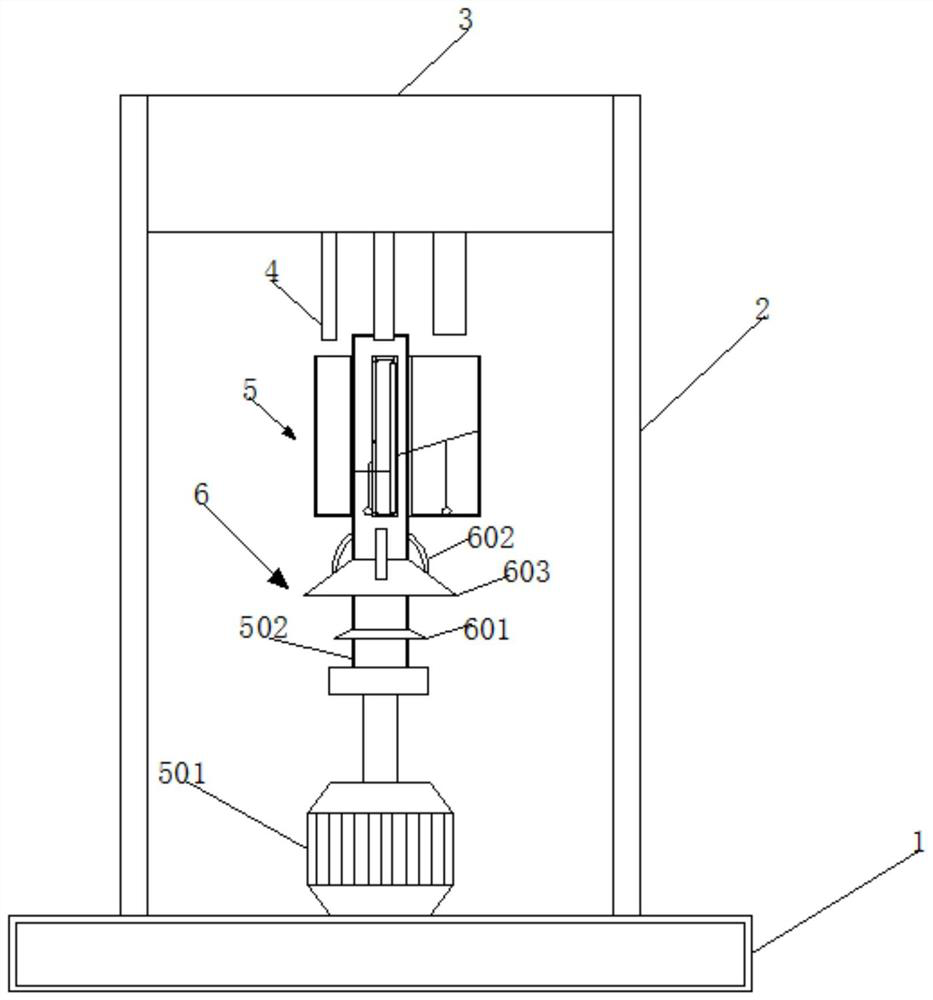

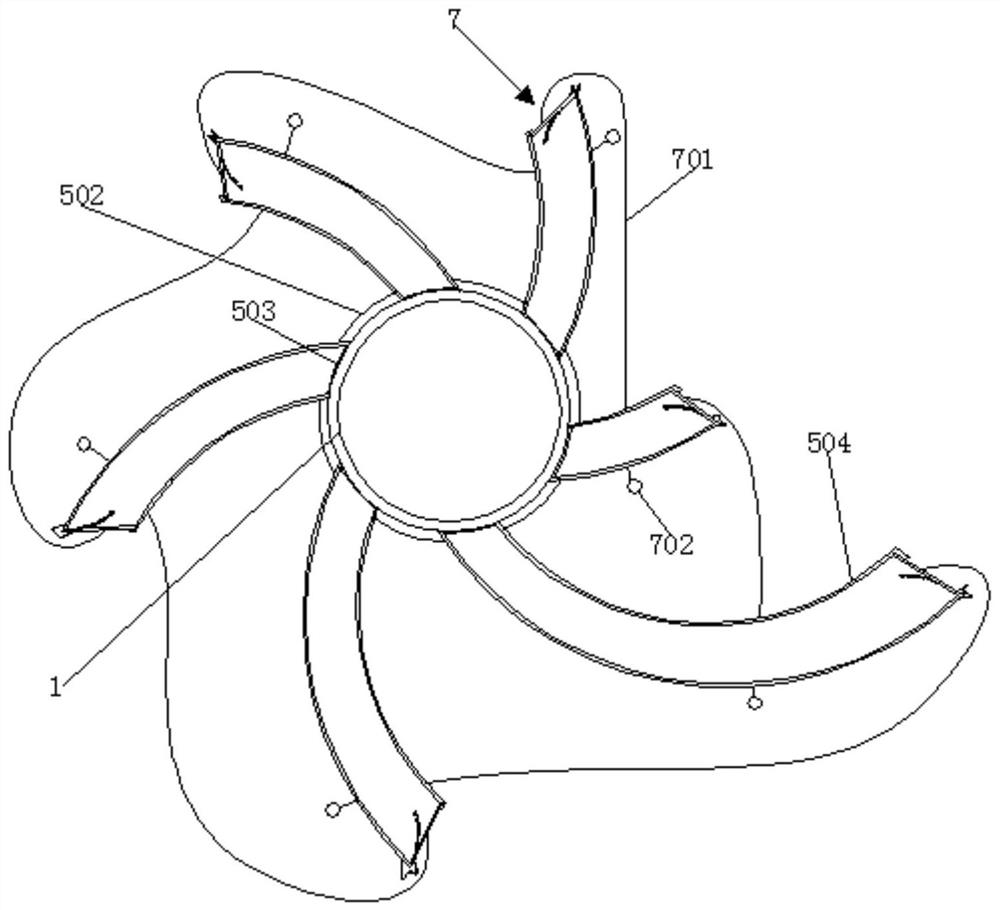

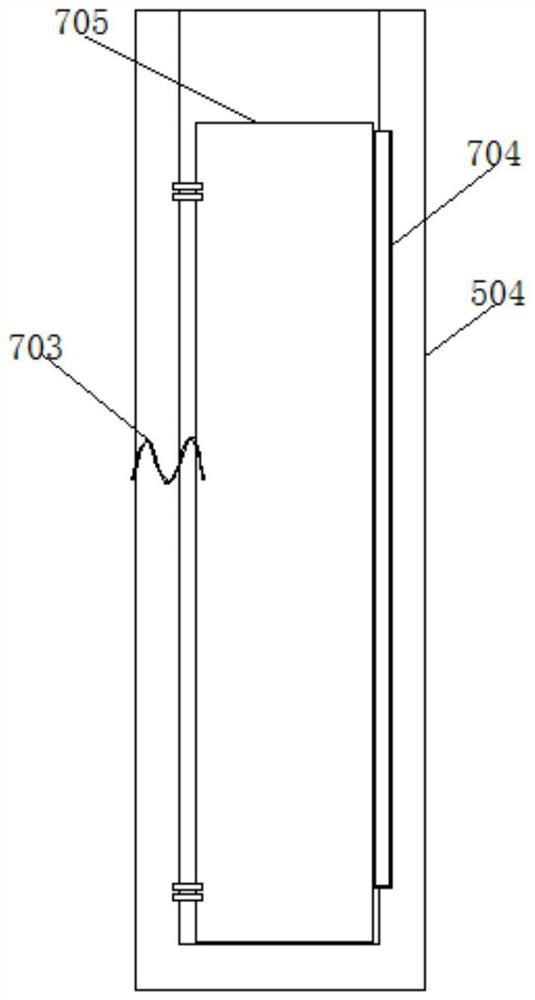

[0028]Such asFigure 1-8As shown, the present invention provides a technical solution: a polishing machine having a large arbitral area, including a floating block 1, and a floating block 1 is fixedly connected to a bracket 2, and the bracket 2 side wall is fixedly mounted. 3, the hopper 3 in the bottom of the hopper 3 The amount of pump 4 is provided, the number of the pump 4 is six, and the six-type pipe 4 has an inconsistency, and the six-position position of the six-pitched tube corresponds to the inner diameter from the large to small. 504 Above, the inner portion of the head 3 is provided with a raised portion, and the floating block 1 is provided on the floating block 1, and the polishing mechanism 5 is provided on the polishing mechanism 5 and the automatic discharge mechanism 7.

[0029]The polishing mechanism 5 includes a rotary electric machine 501, a rotary rod 502, a placed bin 504 that is different from six sizes, and the rotary electric machine 501 is fixedly mounted at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com