Steel structure anti-buckling support reinforcement device and building

A technology of anti-buckling support and reinforcement device, which is applied in the direction of building construction, protective buildings/shelters, buildings, etc. It can solve problems such as collapse, large anti-lateral stiffness, and damage to original structure openings, and achieves easy installation and disassembly , Reduce space occupation, simple and convenient operation

Active Publication Date: 2022-01-28

NORTHEAST DIANLI UNIVERSITY

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, steel structures such as large factory buildings have high requirements for space. In order to meet the space requirements, the overall span of the steel structure is relatively large and the lateral stiffness is small. Local damage or even overall collapse caused by low lateral stiffness

For some large industrial plants, it is necessary to meet certain clearance requirements under the beams, so it has caused certain difficulties in the reinforcement of the structure. It is difficult to strengthen the structure without affecting the spatial layout of the structure and satisfying the requirements of the beams. lower headroom requirements

[0004] At present, the steel structure reinforcement support structure in the prior art is very simple, basically a pure steel structure support, the inventors found that the existing simple steel structure support is difficult to meet the reinforcement requirements, and at the same time, ordinary reinforcement devices can only Fixed in a specific position, it cannot be adjusted or replaced after installation until it is damaged, and it cannot be reused. It will cause permanent damage to the original structure, such as opening holes, and there is no way to replace it and adjust it to deal with different conditions. Reinforcement requirements, the reinforcement position is completely fixed, and cannot adapt to the change of load. After the structure is reinforced, it is easy to self-destroy in severe natural disasters, which is not conducive to structural safety.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0064] This embodiment discloses a building, in which the anti-buckling support reinforcement device for steel structures described in Embodiment 1 is installed between the set horizontally arranged first steel girders and vertically arranged second steel girders, the building Other structures adopt the existing structure, which will not be described in detail here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

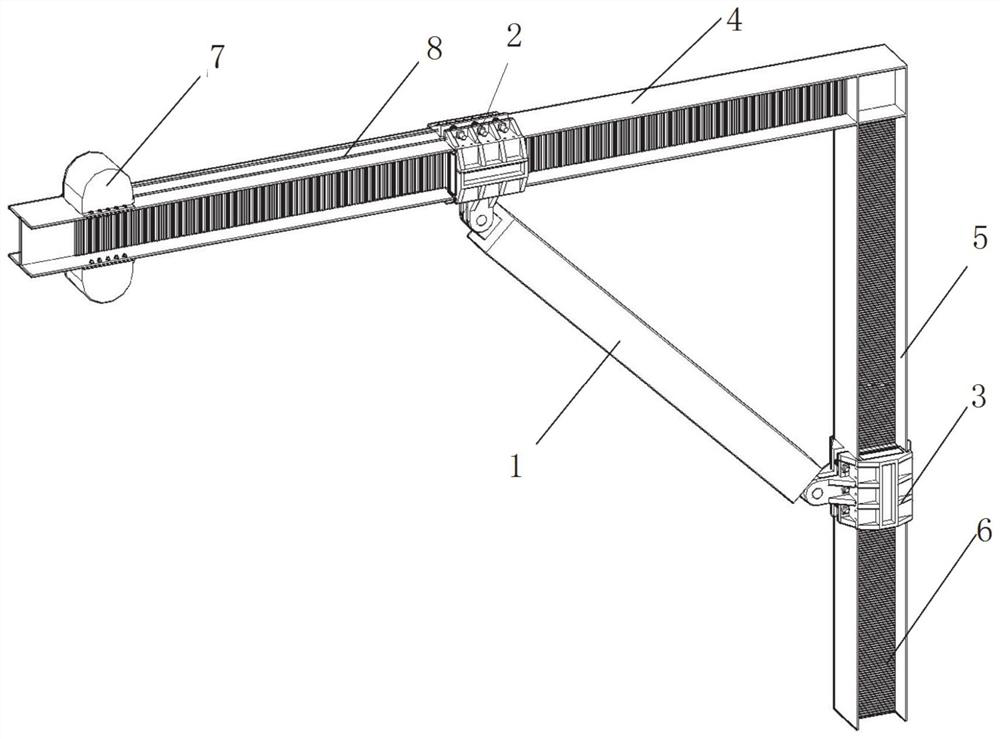

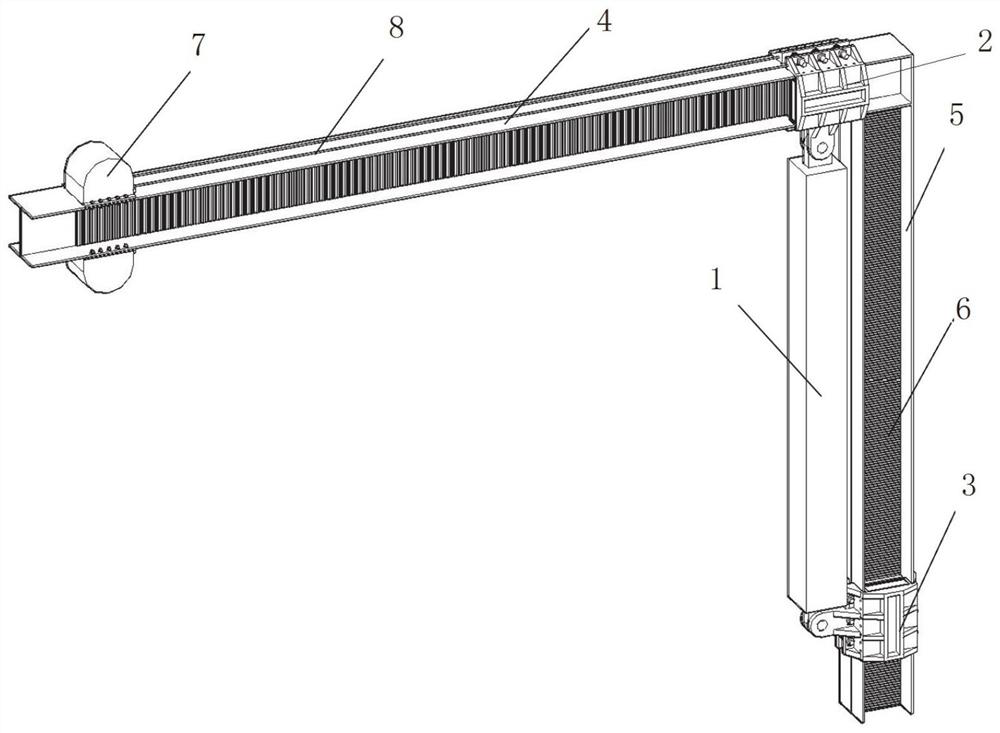

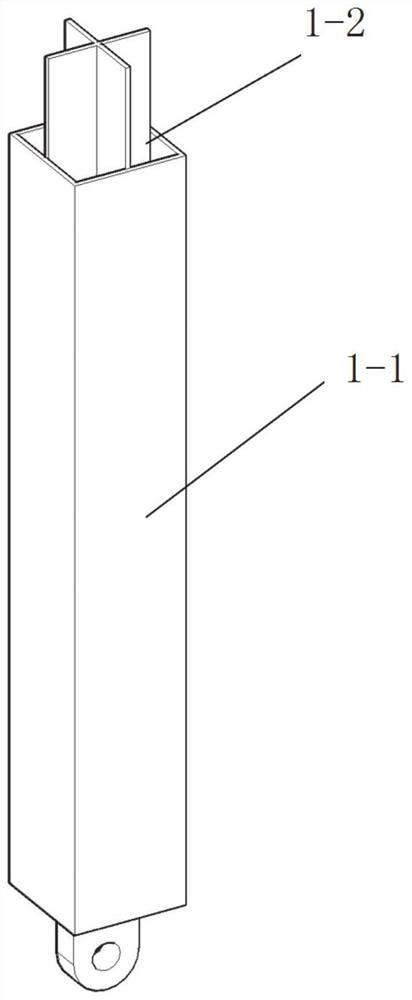

The invention relates to a steel structure anti-buckling bracing reinforcement device and a building, including the buckling-resistant bracing, the two ends of the anti-buckling bracing are hinged with fixers, and one of the fixers can be connected to one of two steel beams perpendicular to each other. The steel beam is slidably connected, and the other fixer can be slidably connected with another steel girder. The fixer includes a shell, and the shell is equipped with a locking mechanism. The fixer can be locked and fixed with the steel beam through the locking mechanism. The reinforcing device of the present invention It can be adjusted according to the reinforcement requirements, and there will be no abandonment of the original reinforcement device due to changes in the reinforcement requirements and no secondary damage to the original structure due to re-reinforcement.

Description

technical field [0001] The invention relates to the technical field of steel structure buildings, in particular to a steel structure anti-buckling support reinforcement device and a building. Background technique [0002] The statements herein merely provide background information related to the present invention and do not necessarily constitute prior art. [0003] Steel structure is a structure composed of steel materials. It is one of the main types of building structures. Its structure mainly includes steel beams, steel columns, steel trusses and other components made of steel and steel plates. Connected by welds, bolts or rivets. Because of its light weight and easy construction, it is widely used in large factories, stadiums, super high-rises and other fields. However, because steel structures such as large factory buildings have high requirements for space, in order to meet the space requirements, the overall span of the steel structure is large and the lateral stif...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E04B1/98E04H9/02E04B1/343

Inventor 刘春城杨爱全

Owner NORTHEAST DIANLI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com