Emulsifying device for producing essence and using method

An emulsifying device and essence technology, applied in chemical instruments and methods, mixing methods, mixers with rotary stirring devices, etc., can solve the problems of shaking of emulsifying tank, increased heating cost, poor emulsifying heating effect, etc., and achieve convenient operation. , Improve the overall portability and ensure the effect of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

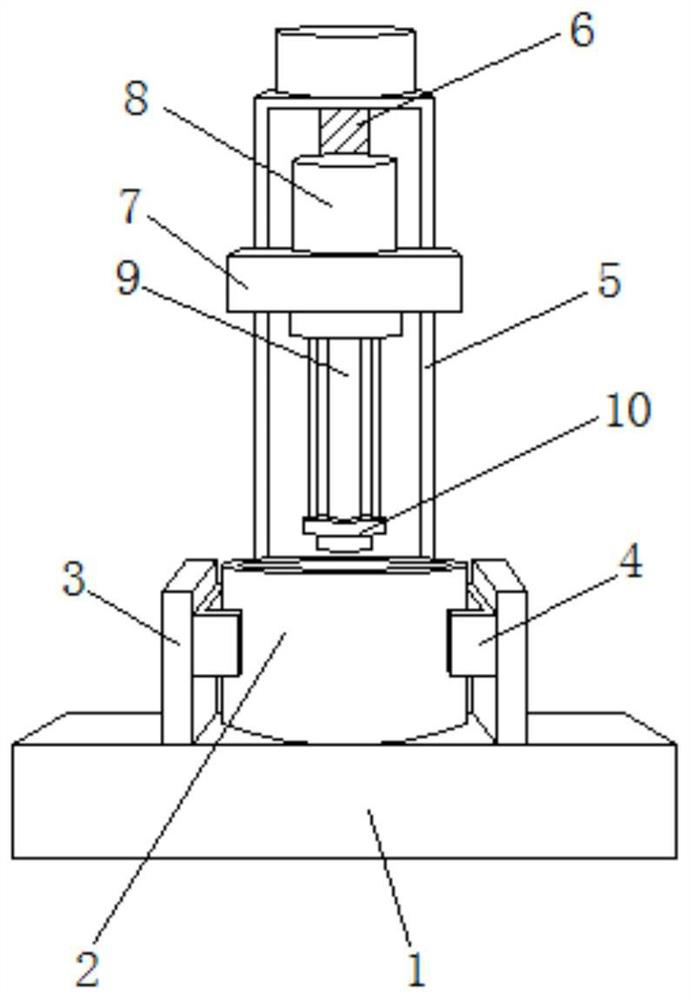

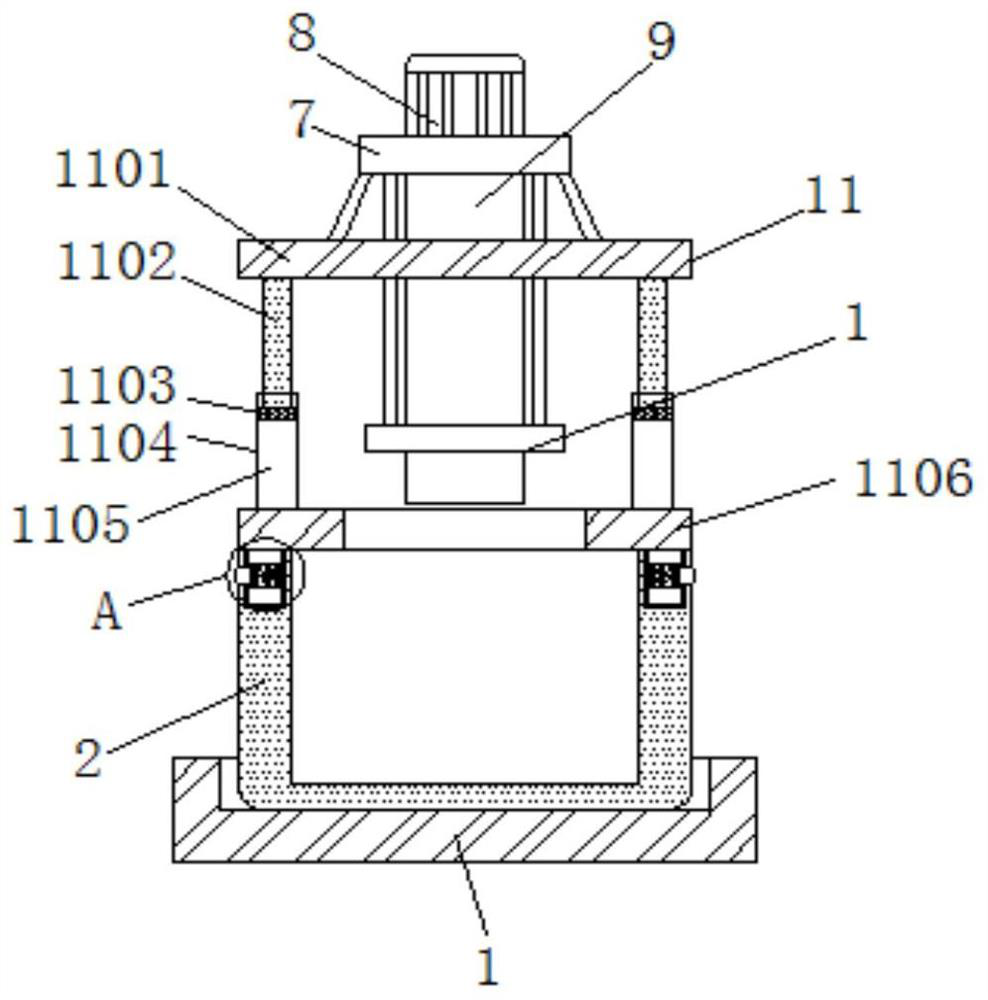

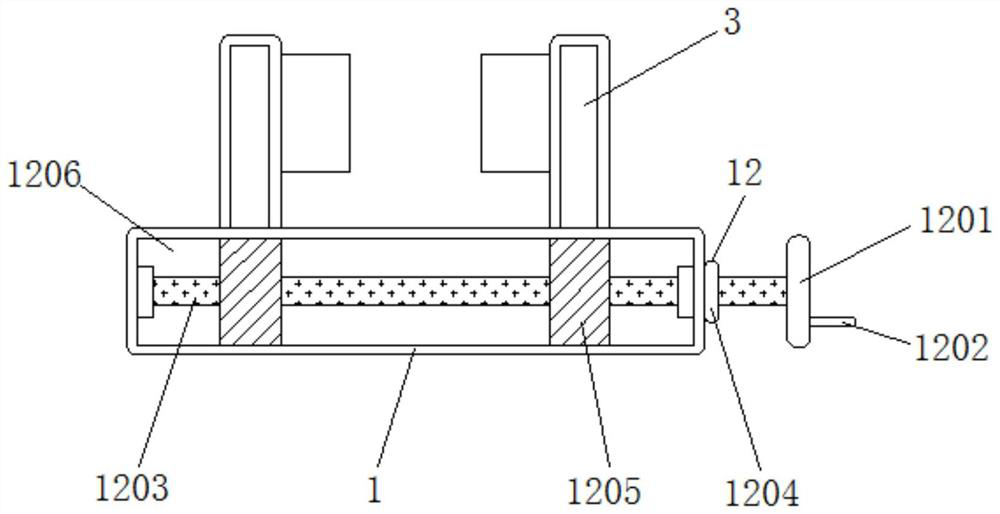

[0029] Such as Figure 1-Figure 6As shown, an emulsification device for producing essence includes a base 1, an emulsification tank 2, a retaining plate 3, a concave plate 4, a fixed frame 5, an electric push rod 6, a movable frame 7, a driving motor 8, a transmission shaft 9, Emulsification head 10, emulsification alignment mechanism 11, upper positioning plate 1101, positioning post 1102, first guide block 1103, fixed column 1104, first guide groove 1105, lower positioning plate 1106, alignment column 1107, alignment groove 1108 , the second guide groove 1109, the second guide block 1110, the first spring 1111, the block 1112, the emulsification retention mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com