Manual steamed bun frying machine

A fried bun machine and handle technology, which is applied in the field of fried bun tools and fried bun, can solve the problems of frying buns, such as troublesome, increased income, slow floor space, etc., to achieve the effect of improving profits, high efficiency and good customer service

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

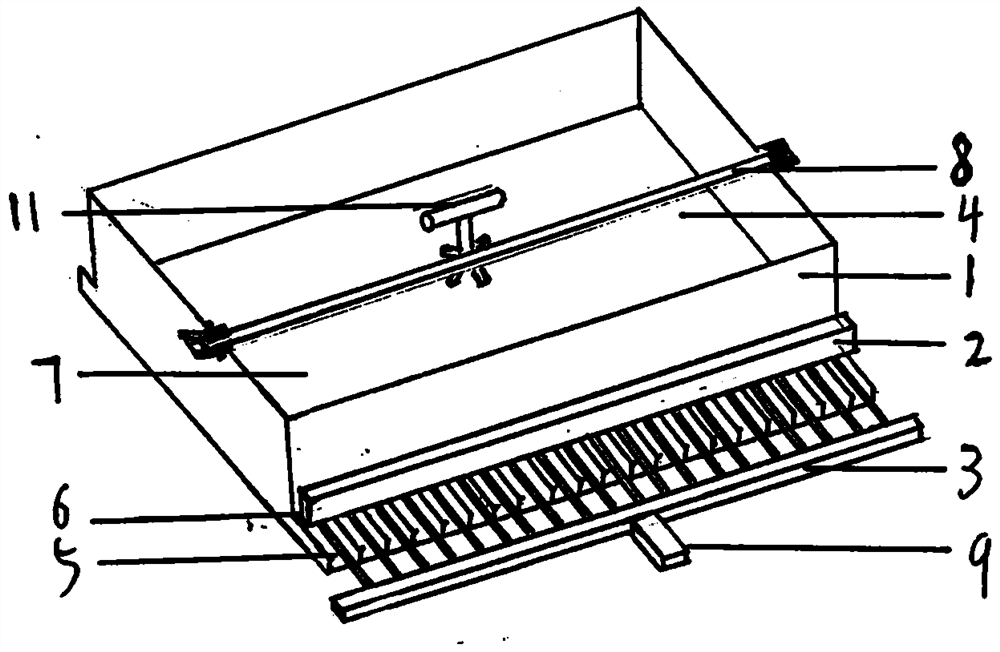

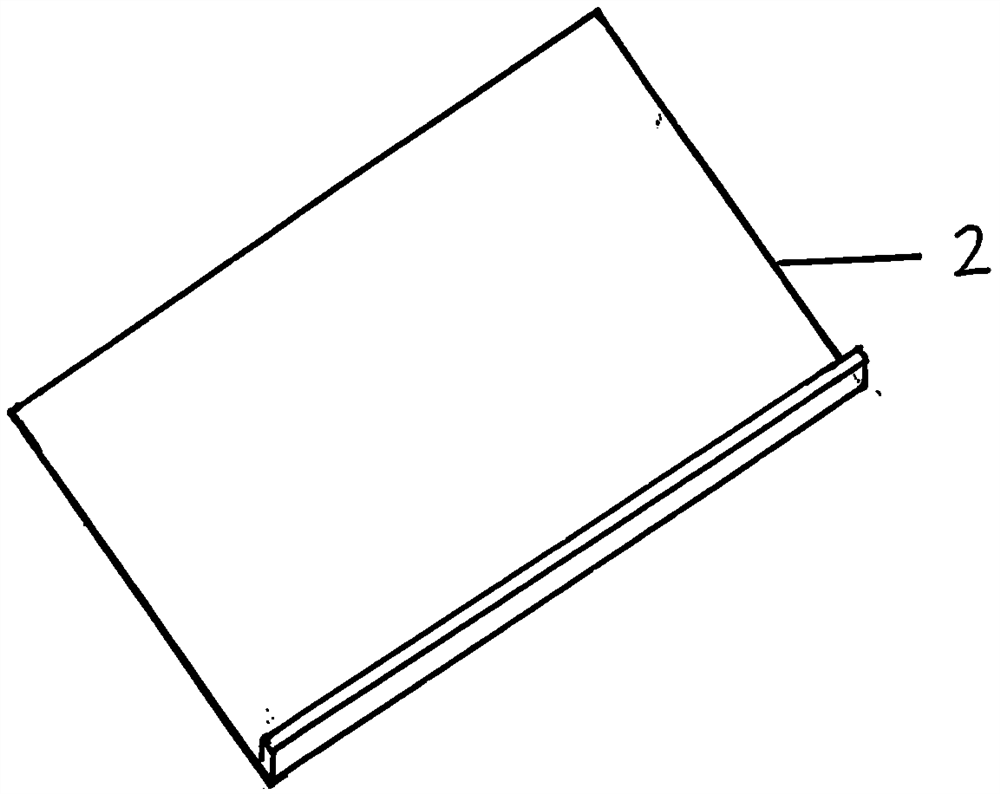

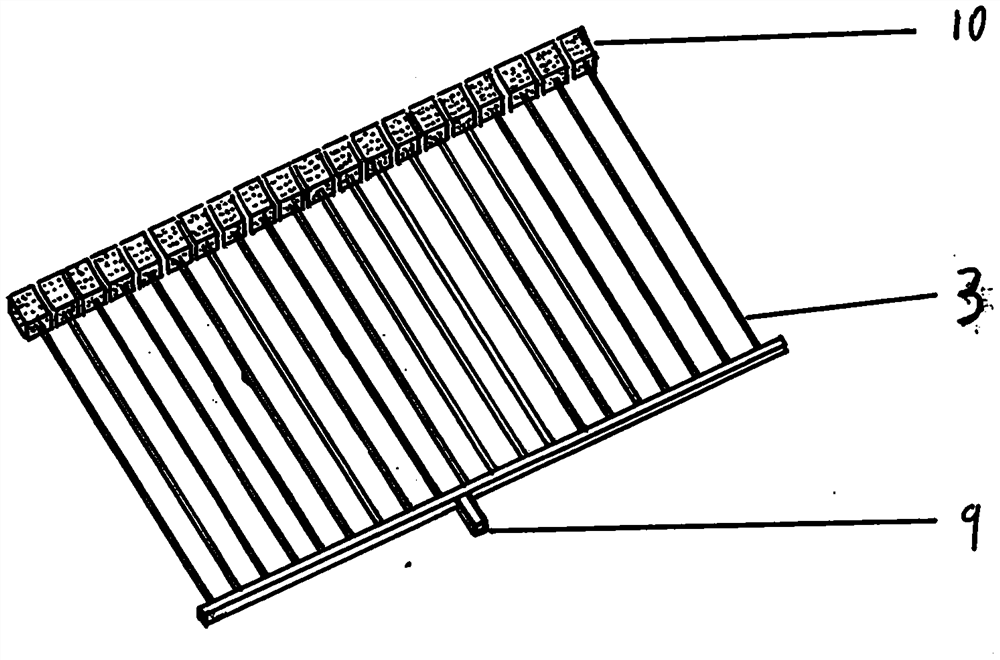

[0012] as attached figure 1 , the product of this embodiment is a kind of manual steamed bun machine used in snacks and other dining places. In order to ensure safety and sanitation and better operation, a manual fried steamed bun machine is made of stainless steel. Toweling strips. The manual steamed bun machine is easier to operate and more efficient than pure manual fried steamed buns. as attached figure 1 Shown, present embodiment product is long 30cm, wide 20cm, high 15cm or bigger size. A kind of manual deep-fried steamed bun machine of the product of the present embodiment is provided with a stereotyped main body (1), a noodle cutter (2), a noodle brushing fork (3) and a pressure plate (4) on the top. The shaping body (1) is provided with a plurality of shaping grooves (5), holes (6) for inserting and pulling out the noodle cutter (2), noodle filling grooves (7) and handles (8). Oil brushing and noodle pushing fork (3) is provided with handle (9) and a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com