Preparation and molding process of multi-strand wire harness cable

A molding process and multi-strand wire technology, which is applied in the direction of cable/conductor manufacturing, conductor/cable supply device, electrical components, etc., can solve the problems of misaligned ends, affecting the quality of wires, loose ends of wires, etc., and achieve the effect of preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

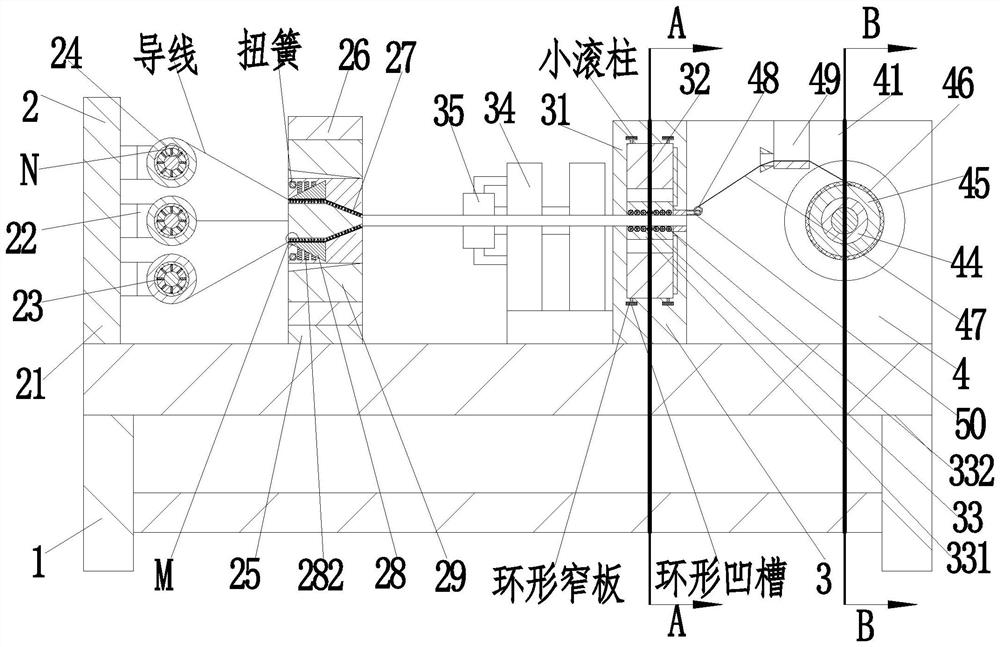

[0041] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

[0042] A multi-strand cable preparation and molding process, which uses a multi-strand cable preparation and molding equipment, the multi-strand cable preparation and molding equipment includes a workbench 1, a transport device 2, a positioning device 3 and a winding device 4. The specific method for preparing and molding multi-strand cables by using the above-mentioned multi-strand cable preparation and molding equipment is as follows:

[0043] S1. Fixing the wire reel: fixing the wire barrel to be twisted on the transportation device 2;

[0044] S2. Positioning the wire: Pull the wire to the right until the end of the wire is located on the right side of the positioning device 3. At this time, the right side of the wire is pressed and fixed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com