Building construction material mixing device

A material mixing and building construction technology, which is applied in the direction of mixers, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems affecting the mixing efficiency of materials, and achieve the goal of improving mixing efficiency, preventing fluidity and avoiding clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

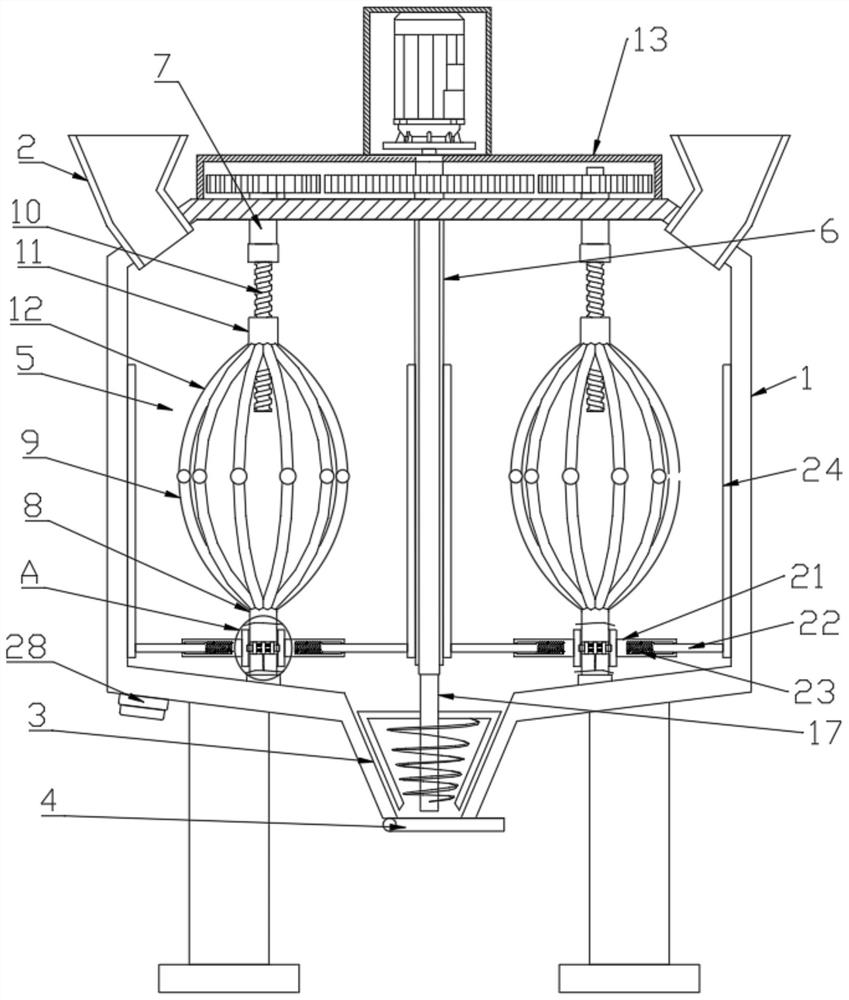

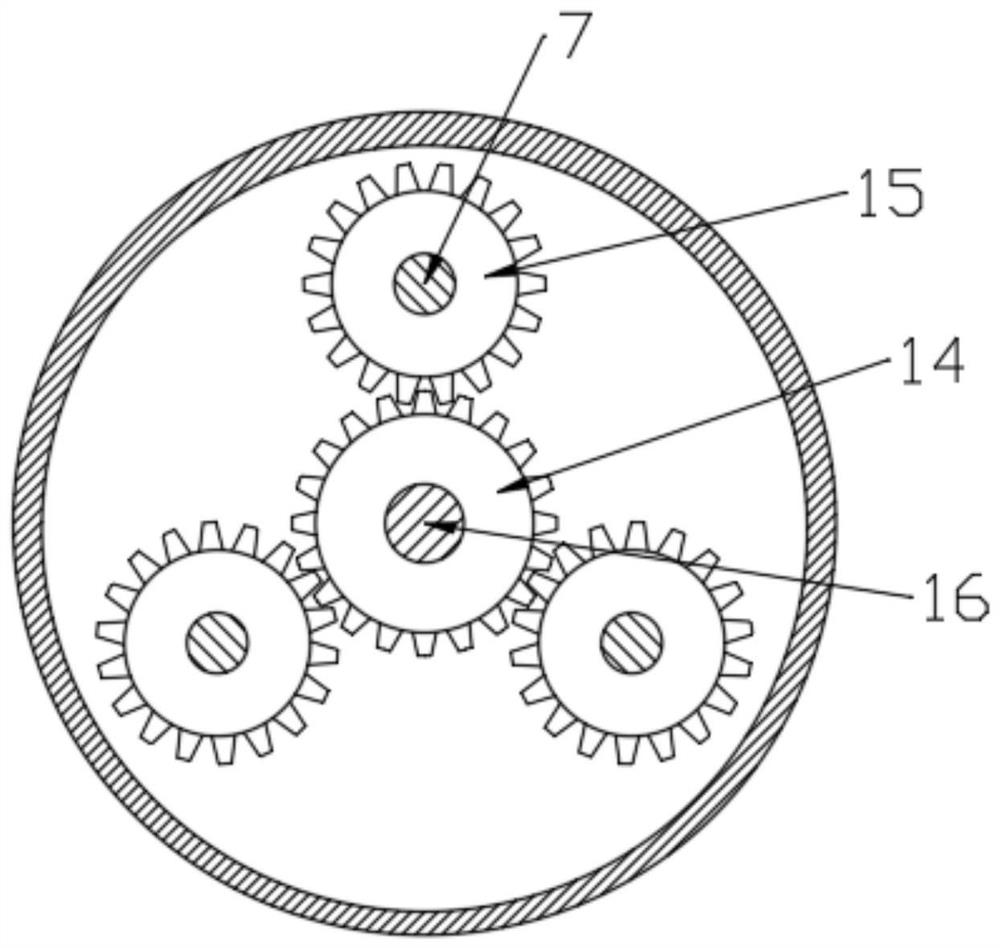

[0023] see Figure 1-4 , a material mixing device for building construction, comprising a housing 1, the top surface of the housing 1 is symmetrically provided with a feed channel 2, and the bottom of the housing 1 is provided with a discharge channel 3, and the discharge channel 3 It is in the shape of a cone, and the bottom of the discharge channel 3 is hinged with an on-off valve 4. The inside of the housing 1 is divided into a plurality of stirring chambers 5 through a partition 6. The stirring chamber 5 is provided with a stirring mechanism. The top of the body 1 is provided with a driving mechanism that drives multiple stirring mechanisms to operate simultaneously. The stirring mechanism includes a first rotating shaft 7, a second rotating shaft 8, a stirring paddle 9, a threaded rod 10 and a threaded sleeve 11. The first rotating shaft 7 Rotately connected with the top surface of the housing 1, the threaded rod 10 is fixed on the bottom of the first rotating shaft 7, an...

Embodiment 2

[0028] This embodiment describes the scraping mechanism in detail on the basis of Embodiment 1, specifically:

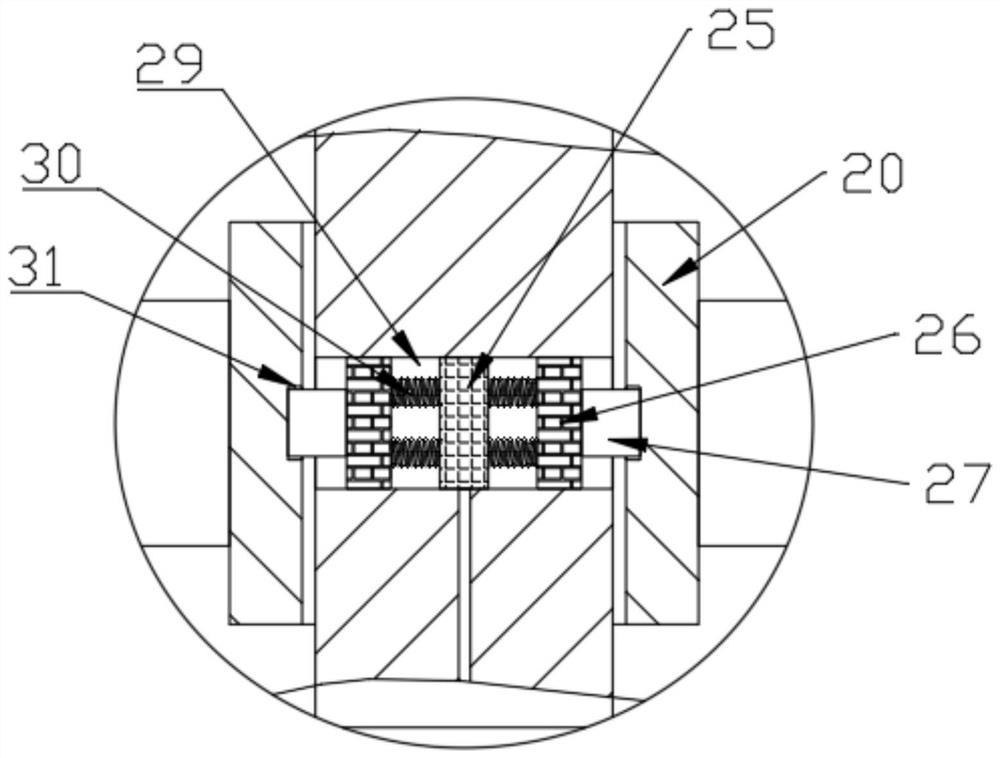

[0029]The scraping mechanism includes a sleeve block 20, a telescopic sleeve 21 and a telescopic rod 22, the sleeve block 20 is installed on the second rotating shaft 8 through a connecting assembly, and the outer surface of the sleeve block 20 is fixed with a telescopic sleeve 21 One end of the telescopic rod 22 is slidably connected in the telescopic sleeve 21, and the telescopic rod 22 is provided with a first spring 23 between the telescopic sleeves 21, and the other end of the telescopic rod 22 is fixedly provided with a scraper 24. The scraper 24 is rotatably connected with the inner wall of the housing 1 and the partition plate 6; the connecting assembly includes an electromagnet 25, a permanent magnet 26, a limit block 27 and a switch button 28, and the switch button 28 is arranged on the bottom surface of the stirring tank. The second rotating shaft 8 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com