Automatic press-in device for flat wire hairpin coil and stator iron core

A press-in device and stator core technology, applied in the direction of electromechanical devices, electric components, manufacturing motor generators, etc., can solve the problem of low efficiency, failure to realize automatic press-in of stator cores with different thicknesses and flat wire hairpin coils, Manpower and other issues are required to achieve the effect of relative position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

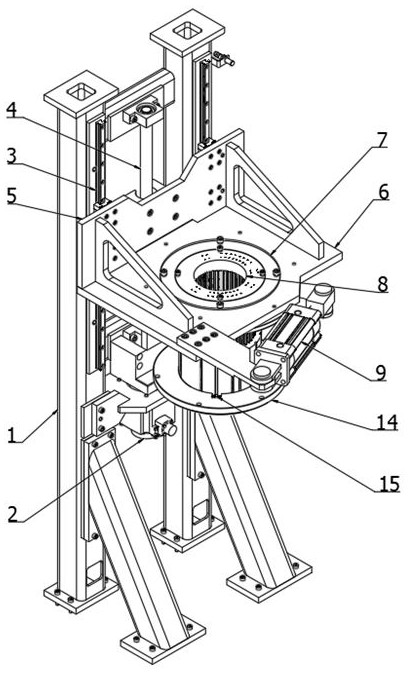

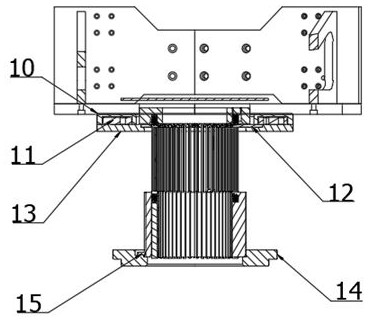

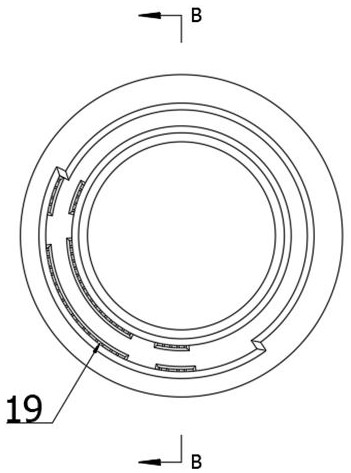

[0015] refer to Figure 1-Figure 7 . An automatic press-in device for a flat wire issuing coil and a stator core. A servo motor 2 and a linear guide rail 4 are installed on a frame body 1; the servo motor 2 is connected to a lead screw 3; the nut on the lead screw 3 is fixedly connected to a connecting plate 5; On the linear guide rail 4, the slider is fixedly connected with the connecting plate 5; the connecting plate 5 is fixedly connected with the floating plate 6; Slot locating plate 8 and pin-slotting locating plate at the end of the hairpin coil are fixedly connected; the locating plate 8 of the special-shaped flat wire hairpin slot is provided with guide chamfer 16 as a whole of the flat wire coil, leading chamfer 17 of the hairpin wire, and positioning of the end face of the flat wire coil Surface 18, leading out the clip line positioning groove 19; the hairpin positioning plate at the end of the clipping coil includes the upper positioning plate 10, the rotating disk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com