Natural resource monitoring device

A technology for monitoring devices and natural resources, applied in measuring devices, mechanical measuring devices, using mechanical devices, etc., can solve problems such as large errors, inaccurate adjustment, and different adjustment positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

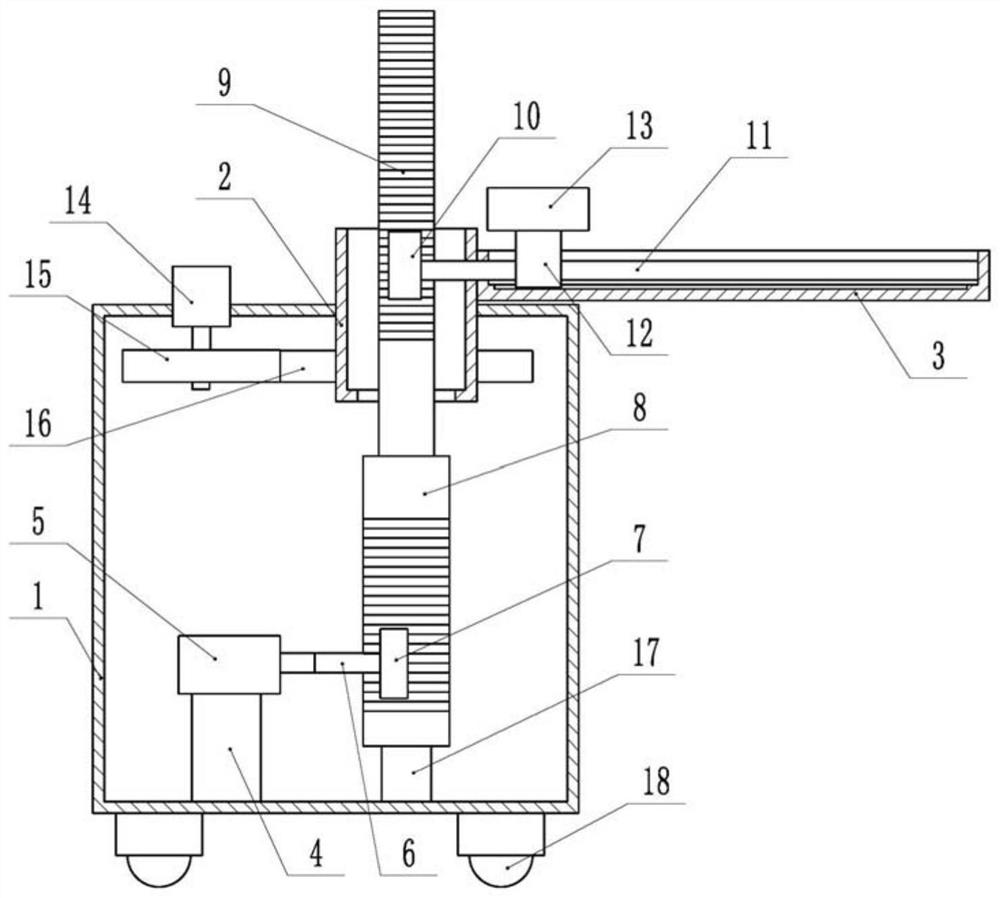

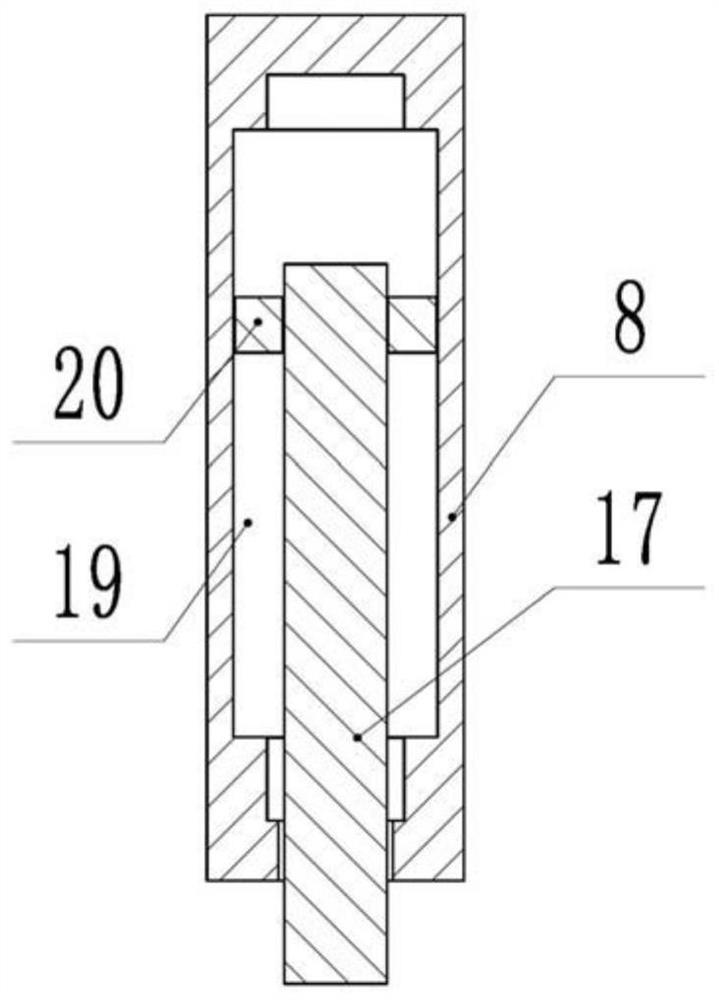

[0030]Embodiments are basicallyfigure 1 As shown: a natural resource monitoring device, including the mounting tank 1 and the monitor 13, the inside of the mount 1, the top end of the mounting tank 1 is connected, the support box 2 is hollow, and the top and bottom ends of the support box 2 Both are open ends, the support box 2 in the present embodiment passes through the top end of the mounting tank 1 and rotates through a bearing with the mounting tank 1.

[0031]One side of the support box 2 is fixedly connected to the connecting plate 3, and the connecting plate 3 is located above the mounting tank 1, and the connecting plate 3 is welded to the support box 2. A groove is opened on the connecting plate 3, and a screw 11 is provided in the connecting plate 3, and the screw 11 is located in the recess, and one end of the screw 11 extends into the support box 2 and has a first gear 10 by a flat key. The other end of the screw 11 and the right side wall of the connecting plate 3 rotates...

Embodiment 2

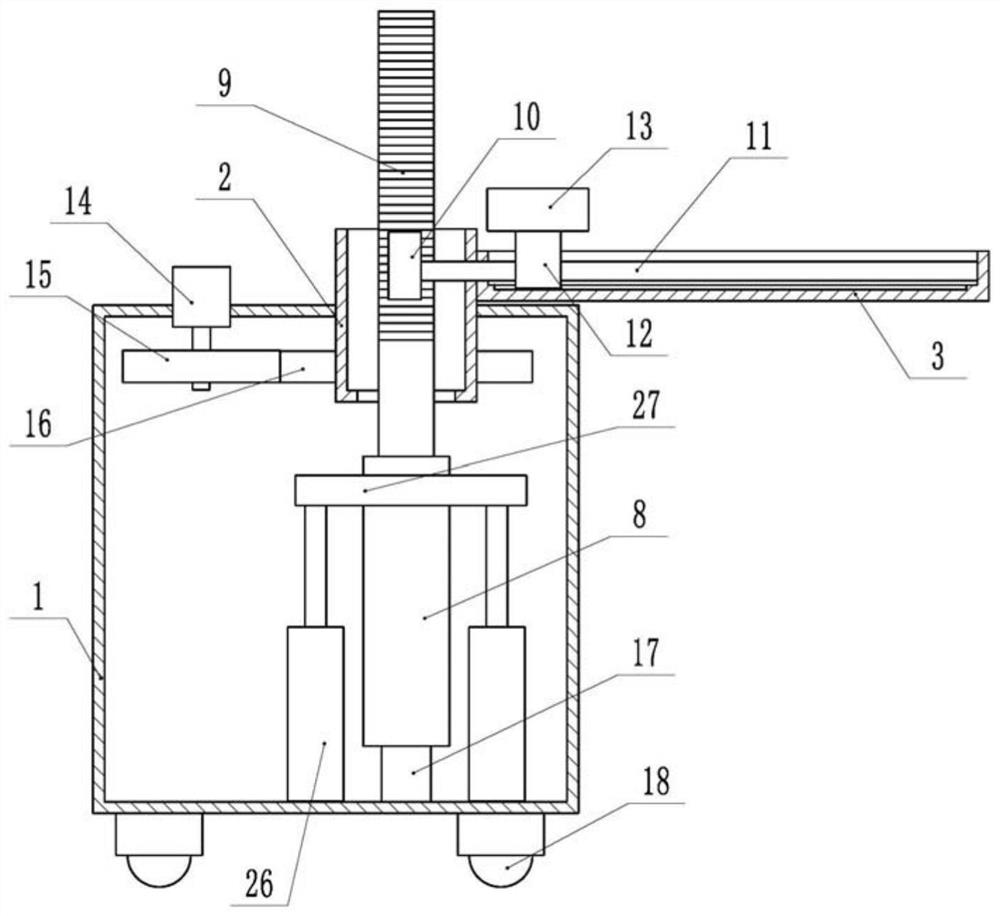

[0041]Such asimage 3 As shown, a natural resource monitoring device, the difference from the embodiment is that the surface of the drive column 8 is smooth, and the surface is not set, and the drive unit includes a cylinder 26 and a branch plate 27, a sheet plate 27 and a drive. The column 8 is rotatably connected by a bearing coaxial, and the output shaft of the cylinder 26 is fixed to the bolt 27, and the cylinder 26 is fixed by the bottom of the cylinder 1 through the bolt.

[0042]When used, the drive column 8 is vertically adjusted by the telescopic movement of the output shaft of the cylinder 26, thereby achieving adjustment of the linear position of the monitor 13, and when the angle of the monitor 13 is required, through the first motor 14 When driving the active gear 15 and the driven gear 16 rotate while driving the support box 2, the drive column 8 can be rotated between the brackets 27, thereby adapting to the support box 2. Turn, in turn, the angular position adjustment of...

Embodiment 3

[0044]Such asFigure 4 As shown, a natural resource monitoring device, the difference from the embodiment is also provided with adjustment block 22 in the connecting plate 3, and the monitor 13 is located on the adjustment block 22 and is fixed to the adjustment block 22 through a bolt. The adjustment block 22 is slidably fitted with the side wall of the connecting plate 3, and in the present embodiment, the slip groove 21 is opened on both sides of the groove of the connecting plate 3, and the front and rear ends of the adjustment block 22 are welded. Block, two bumps are inserted into two slip grooves 21 and slide together with the slip groove 21, so that the adjustment block 22 is a sliding cooperation relationship between the connecting plate 3. In this embodiment, the tip end of the adjustment block 22 is parallel to the top end of the connecting plate 3.

[0045]The natural resource monitoring apparatus in this embodiment further includes an adjustment lever 23, and the adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com