Double-spiral elliptic sealing engagement pair for conveying high-viscosity multi-impurity fluid medium

A fluid medium and multi-impurity technology, which is applied in the direction of rotary piston pumps, rotary piston machinery, liquid fuel engines, etc., can solve the problems of poor adaptability of media containing many impurities, reduced reliability and efficiency of screw pumps, and large volume. Achieve the effects of improving volume utilization, continuous and stable pumping, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

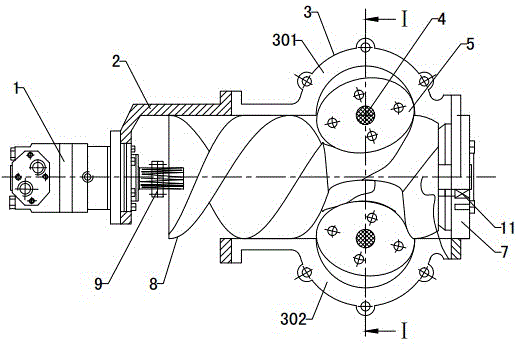

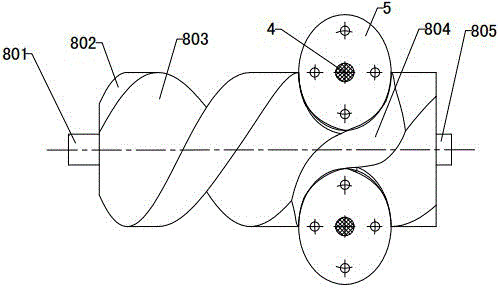

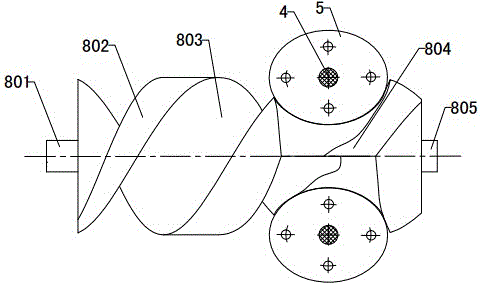

[0028] Figure 1~6 It is the best embodiment of the present invention, below in conjunction with the attached Figure 1~6 The present invention will be further described.

[0029] Refer to attached figure 1: A double-helix elliptical seal meshing pair for high-viscosity and multi-impurity fluid medium transportation, including a screw rotor 8 and a casing 3, the screw rotor 8 is installed in the casing 3, the screw rotor 8 includes an meshing end and a material inlet end, and the screw rotor There are two groups of oval sealing discs 5 symmetrically distributed between the two sides of the meshing end of 8 and the casing 3, and the two groups of oval sealing discs 5 are installed on both sides of the screw rotor 8 through the rotation of the rotating shaft 4, and on the screw rotor 8 The meshing grooves 804 are symmetrically provided with two groups of elliptical sealing discs 5 , the material inlet end of the screw rotor 8 is connected to the power mechanism, and the meshin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com