Accurate alignment and segmented lowering device for large-diameter super-long reinforcement cage and using method

An ultra-long steel cage and large-diameter technology is applied in construction, sheet pile walls, and foundation structure engineering. It can solve problems such as the difficulty in meeting the requirements for the length of the crane arm and the difficulty in hoisting and lowering the ultra-long steel cage, so as to achieve easy transportation and portability. Easy and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

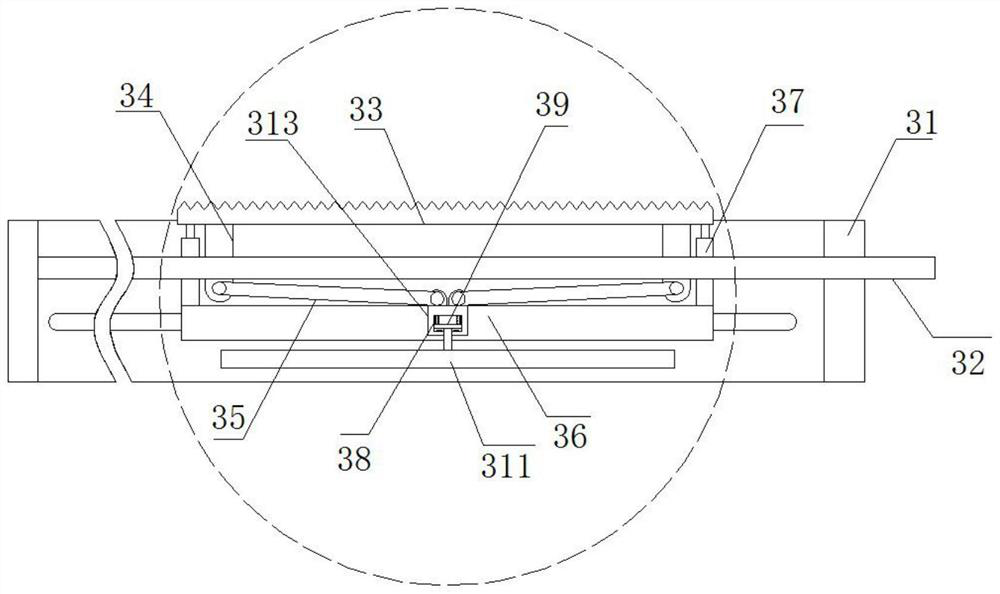

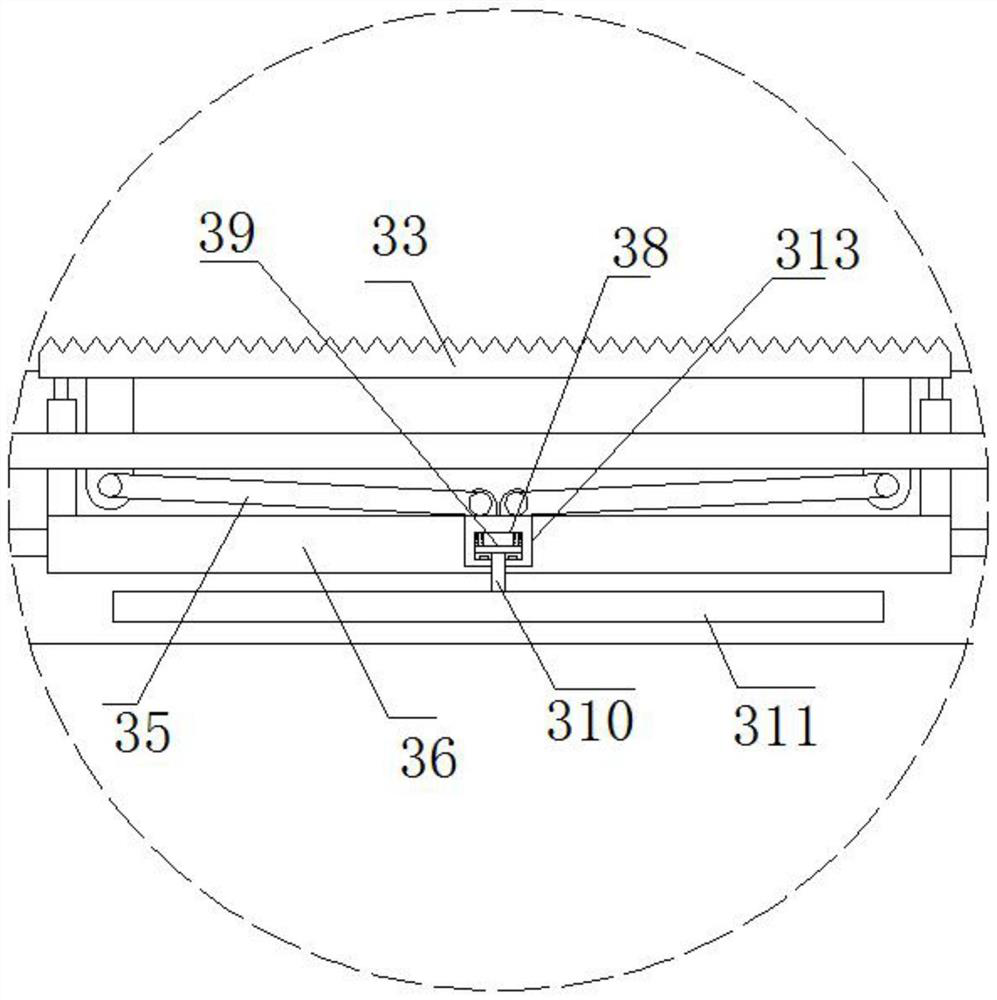

[0041] refer to Figure 1-7 , the device for precise alignment and segmental lowering of large-diameter and super-long steel cages, including a bottom support mechanism 1 arranged in a square shape, characterized in that the top of the bottom support mechanism 1 is slidably connected to a square-shaped moving mechanism 2, and the moving mechanism 2 The alignment mechanism 3 is slidingly socketed on the four sides, and the alignment mechanism 3 extends into the position of the inner ring of the moving mechanism 2 and is detachably connected with a docking mechanism 4;

[0042] The alignment mechanism 3 includes a frame 31 of a rectangular structure that is slidingly s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com