Double-row grenade longitudinal magazine

A grenade-discharging, longitudinal technology, applied in the direction of ammunition supply, weapon accessories, offensive equipment, etc., can solve the problems of undiscovered technical solutions, inconvenient operation and carrying, etc., to achieve convenient operation and portability, reduce volume and weight, increase ammo The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

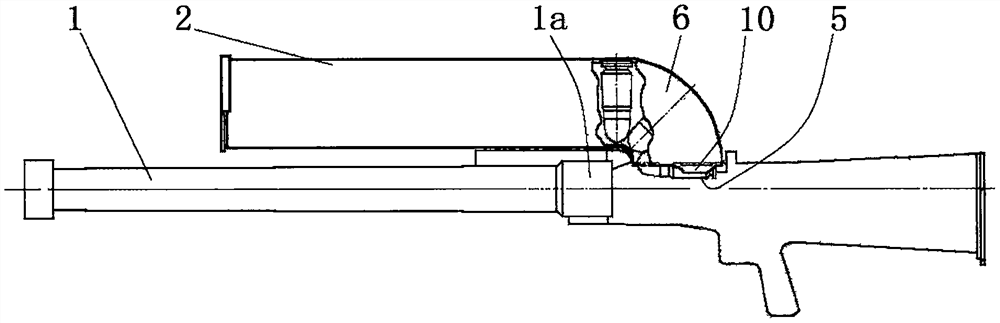

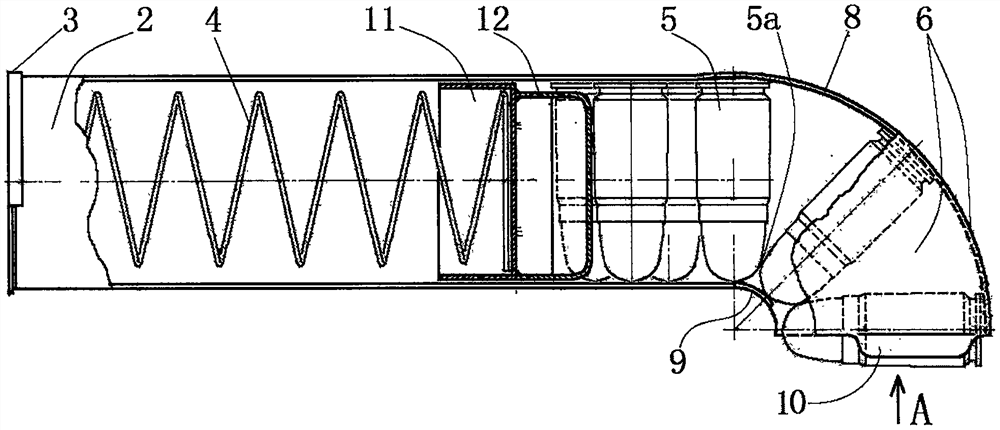

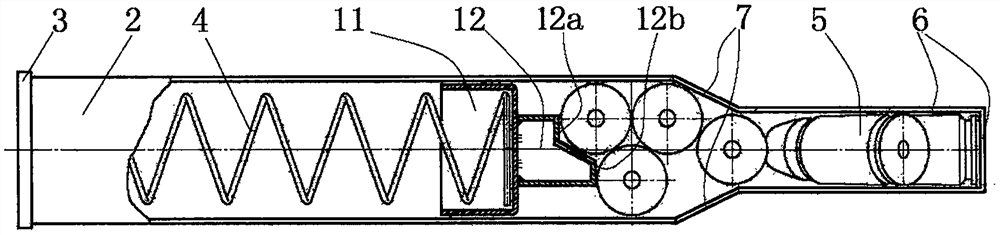

[0031] Embodiment 1: as figure 1 , 2 , shown in 3, a kind of double-row grenade longitudinal magazine is vertically arranged on the top of the gun barrel 1, the bottom of the magazine is towards the muzzle direction, and its main body double-row magazine body 2 is composed of upper, lower, left and right The straight cavity surrounded by four side plates has a magazine cover 3 inserted in its bottom, and the tail end of the push spring 4 is against the inboard of the magazine cover. The above-mentioned structures are all the same as the existing magazines. A group of grenades 5 housed in the double-row magazine body are arranged in double rows staggered, and the grenades are perpendicular to the gun barrel and the top of the bullet is downward.

[0032] The key problem that this magazine needs to solve is how to guide and transfer the grenades perpendicular to the barrel in the double-row magazine to the ready position, that is, to be placed flat on the back and upper side of...

Embodiment 2

[0037] Embodiment 2: According to the longitudinal magazine of the double-row grenade described in Embodiment 1, because the bullet outlet holds the middle section of the grenade 10, the front part of the grenade to be fired in the bullet outlet is suspended in the air. When the firearm vibrates violently , in order to avoid the warhead belly of the grenade from being inclined downward due to the pressure of the inner grenade, an elastic spring support rod 13 is respectively arranged at the front and bottom of the holding teeth on both sides, and their roots are affixed to the same On the outer wall of the front and lower side of the side-hugging bullet teeth, the head end faces forward and is obliquely folded inward. When the bomb is not pushed, the support rods on both sides extend obliquely to the lower left and right sides of the abdomen of the grenade warhead to be fired, respectively. Support the warhead from below to prevent it from falling (such as Figure 11 shown); w...

Embodiment 3

[0038] Embodiment 3: According to the double-row grenade longitudinal magazine described in embodiment 1, in order to avoid the upward jump that may be generated by the grenade to be fired in the bullet outlet when the firearm vibrates violently, on the upper left side and upper right side of the grenade to be fired, each Establish an elastic anti-ballistic rod 14, their roots are respectively fixed on the outer wall of the left side plate and the right side plate at the front top of the bullet outlet, and the head end is backward and obliquely folded inwardly, and stretches obliquely to the side plate to be fired respectively. The upper left side and the upper right side of the middle part of the shell of the grenade shell are close to the shell shell to prevent it from jumping up. The left side plate and the right side plate are provided with rectangular holes (such as Figure 14 shown); after the grenade is pushed out, when the next grenade falls to the bullet outlet, the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com