Incinerator fire grate segment arching on-line detection device

A detection device and grate piece technology, applied in the field of incinerators, can solve problems such as the inability to avoid environmental protection risks and losses, the inability to predict the shutdown of incinerator failures, and the inability to realize online detection of grate piece arching, and achieve the effect of avoiding environmental protection losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

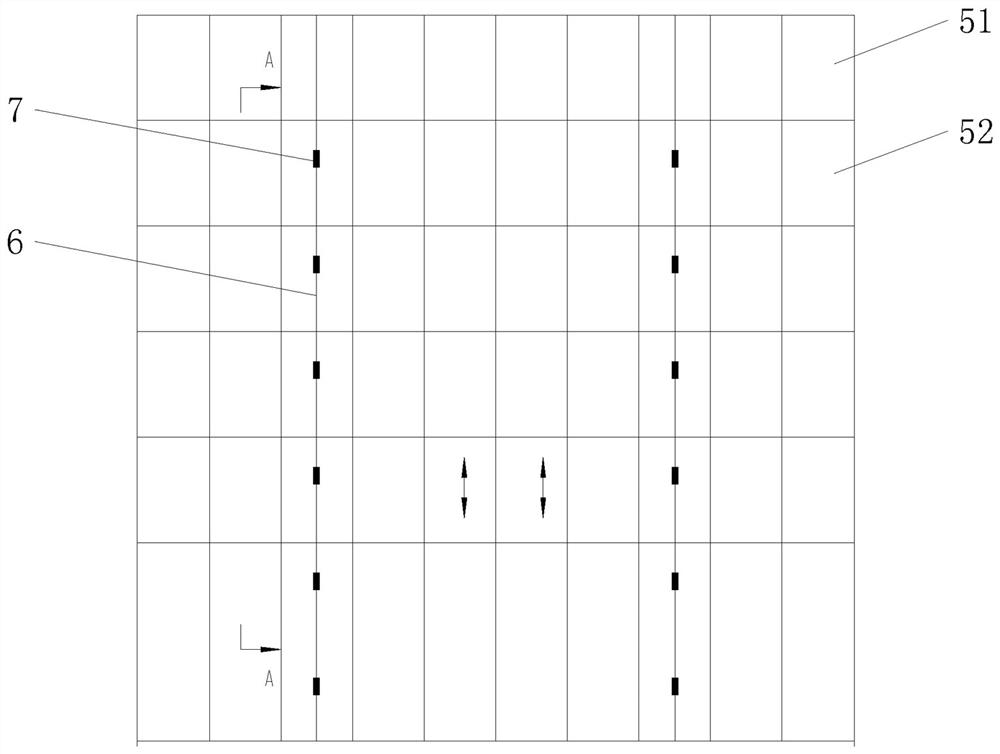

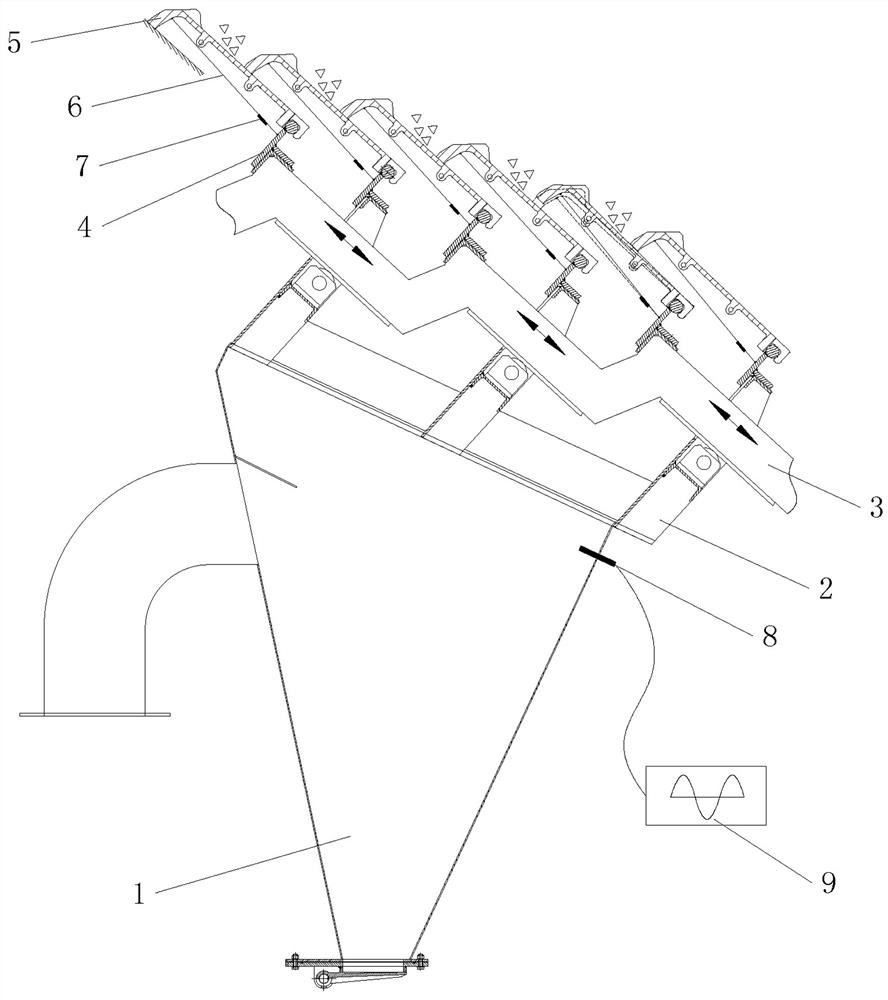

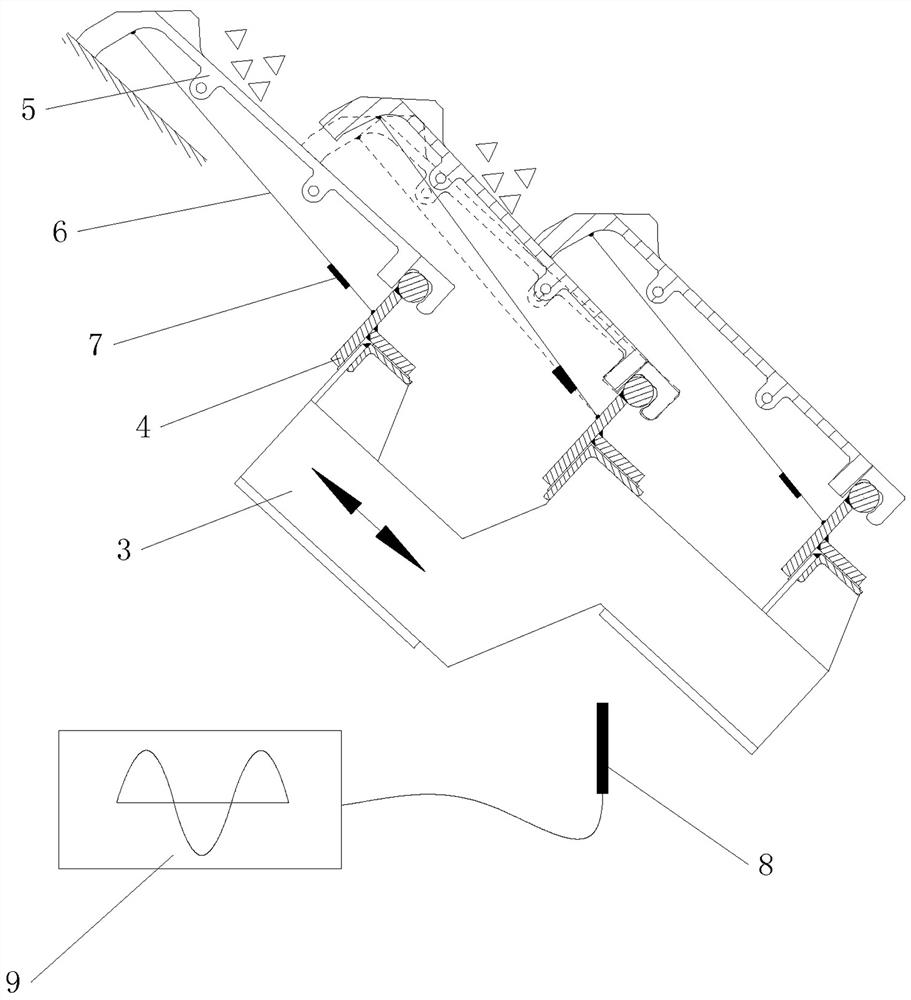

[0018] refer to Figure 1 to Figure 3 , an incinerator fire grate arching online detection device, comprising a wind chamber 1 and a partition 2 fixedly installed on the upper end of the wind chamber 1, the partition 2 is slidably connected with a connecting rod 3, and the partition 2 and the top of the connecting rod 3 are respectively equipped with a support frame 4, and the support frame 4 is rotatably connected with a fire grate 5, and the fire grate 5 includes a moving fire grate 51 and a static fire grate 52, and the moving fire grate 51 is installed on On the connecting rod 3, the static grate 52 is installed on the partition 2, the moving grate 51 and the static grate 52 are arranged at intervals, and the function of the connecting rod 3 is to drive and install on the support frame 4 The moving grate 51 and the static grate 52 reciprocate with a fixed stroke. A transmitter 6 is installed between the support frame 4 and the grate 5. The function of the transmitter 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com