Cylinder cover water feeding pipe positive and negative material recognition reversing device and method

A technology for reversing devices and water pipes, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve the problems of costing manpower and material resources, scratches on the surface of cylinder head processing, and hidden quality problems, so as to improve production efficiency and eliminate serious quality problems. Accidents, the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

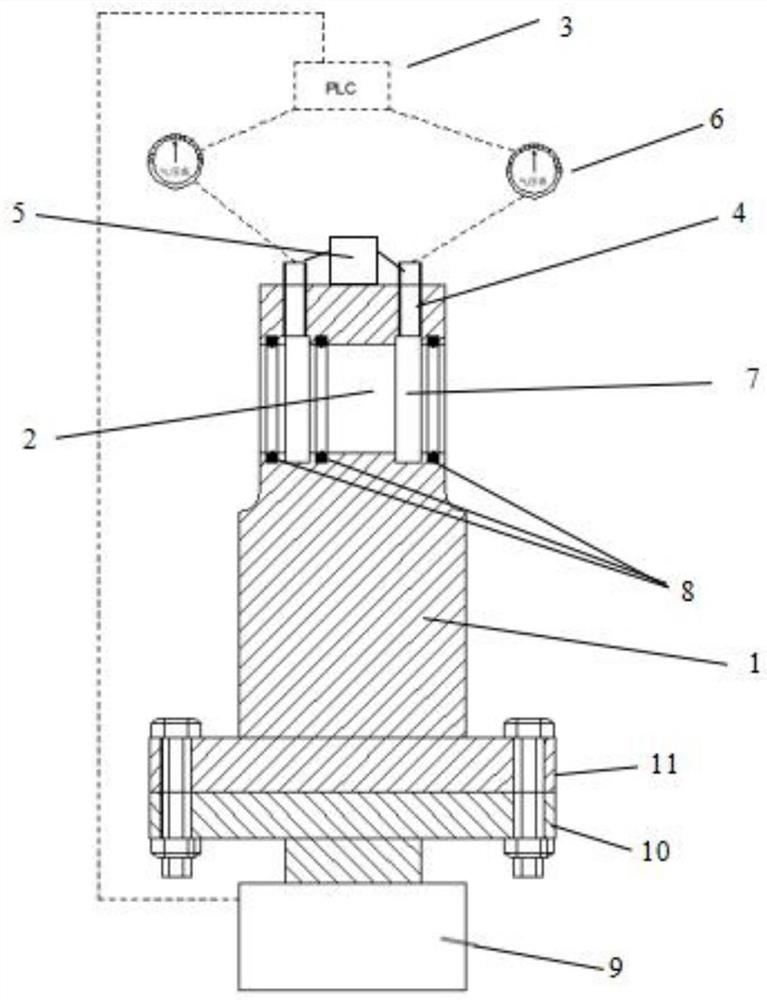

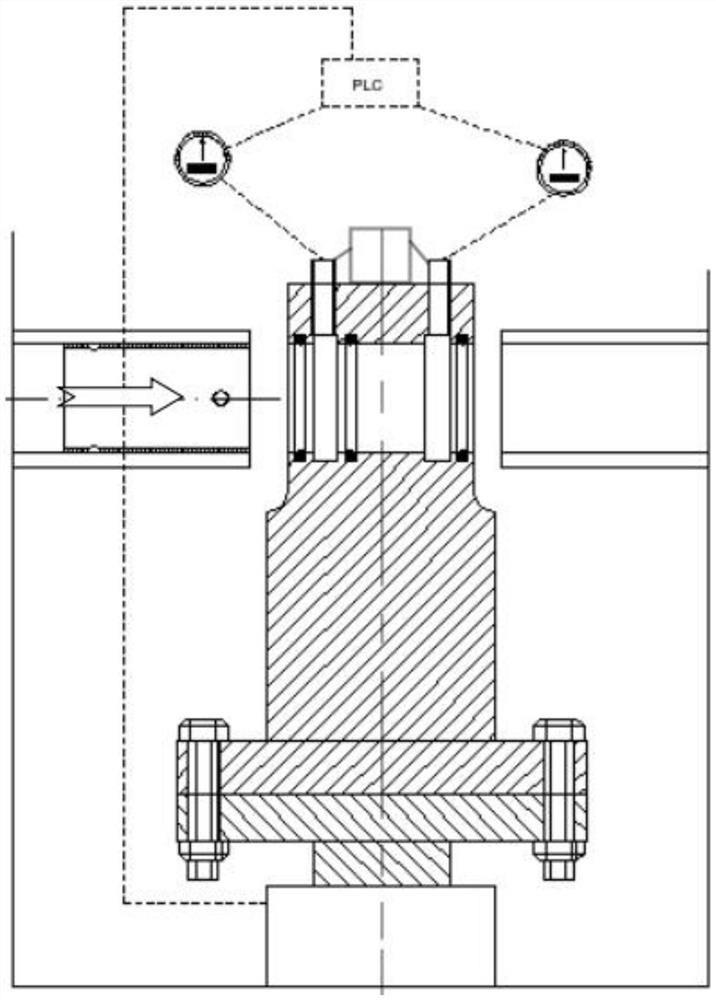

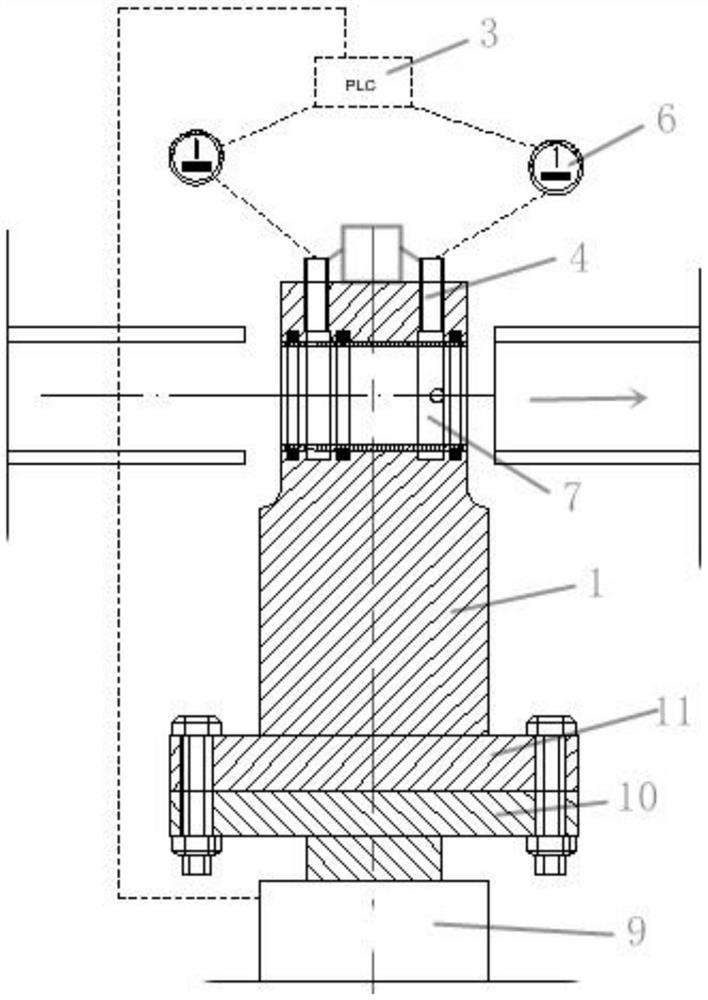

[0037] Such as Figure 1 to Figure 11 As shown, the positive and negative material recognition and reversing device of the water pipe on the cylinder head includes:

[0038] Main body 1, rotating unit and control module 3. The main body 1 is provided with a conveying channel 2 along the conveying direction of the upper water pipe. The conveying channel 2 is provided with fluid pressure to identify the forward direction or direction of the upper water pipe. The identification unit for reverse transportation, the rotation unit is installed on the body 1, the control module 3 is electrically connected to the identification unit and the rotation unit, and the control module 3 controls the rotation unit to drive the body 1 to reverse the upper water pipe to reverse.

[0039] In a further preferred solution in this embodiment, the identification unit includes a detection structure, a fluid channel 4, a fluid source 5 (air source) and a detection element 6 (pressure gauge), and the ...

Embodiment 2

[0060] The identification and reversing method of the positive and negative material of the water pipe on the cylinder head and the reversing device includes the following steps:

[0061] Step 1: The pushing device on the side of the main body 1 pushes the upper water pipe to the inside of the conveying channel 2. At this time, the sealing ring 8, the outer wall of the upper water pipe and the detection channel 7 form two detection areas;

[0062] Step 2: The fluid source 5 feeds fluid into the two fluid passages 4 through the pipeline, and then the fluid enters the detection area. With the passage of the fluid, the two detection elements 6 respectively detect the pressure inside the two detection areas, and the measured The two pressure values obtained are sent to the control module 3, and when the measured two pressure values meet the preset forward delivery conditions in the control module 3, the rotating cylinder 9 will not drive the body 1 to perform the reversing work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com