Lifting swing arm roller replacing device and roller coating unit

A technology of roller changing device and roller coating machine, which is applied in the direction of lifting device, lifting frame, etc., which can solve the problems of low operation accuracy, increased labor intensity and danger of workers, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

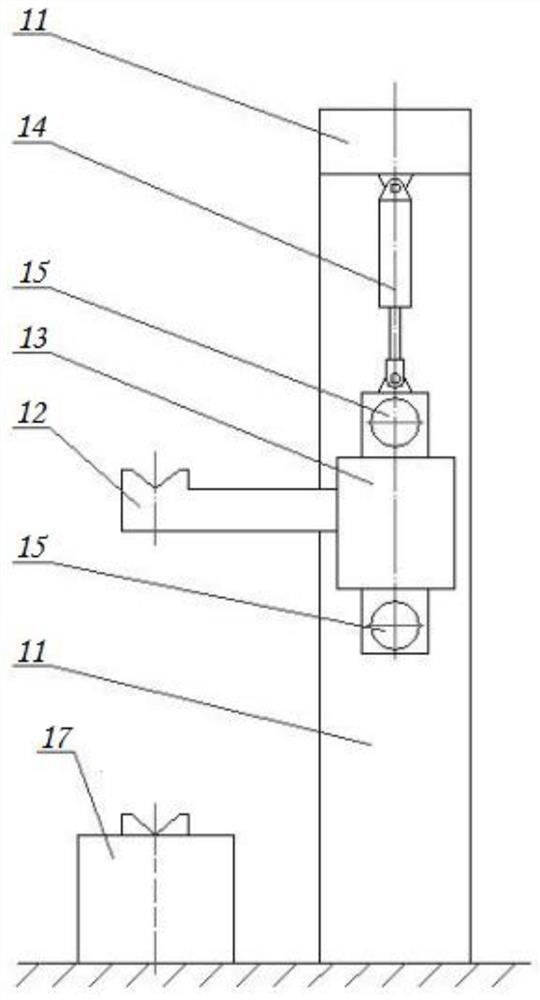

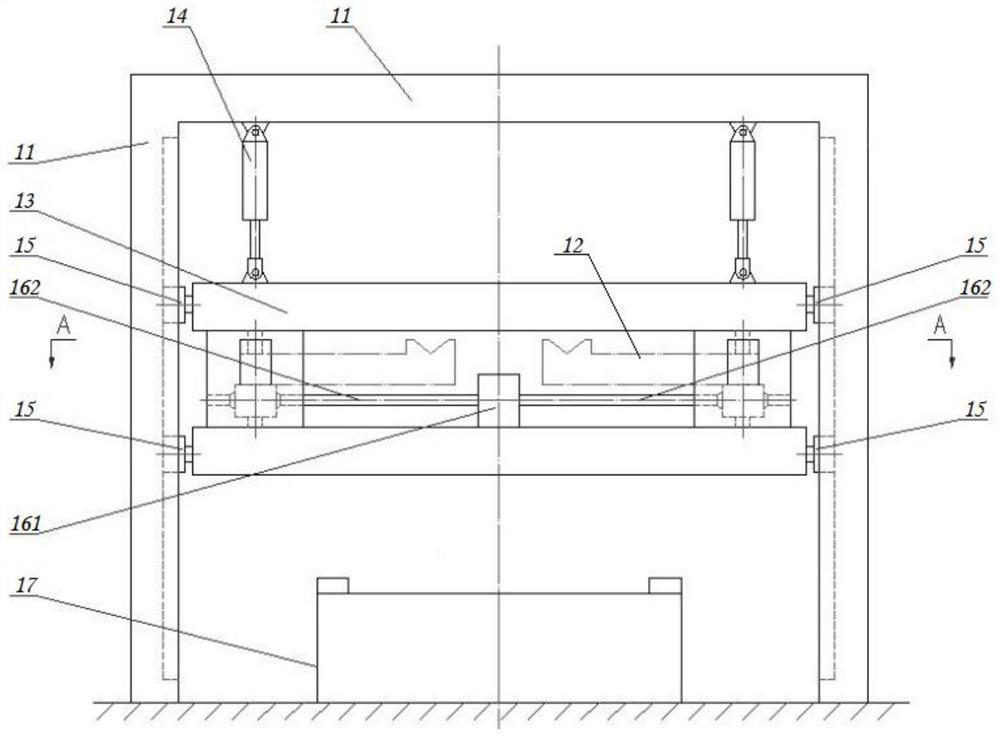

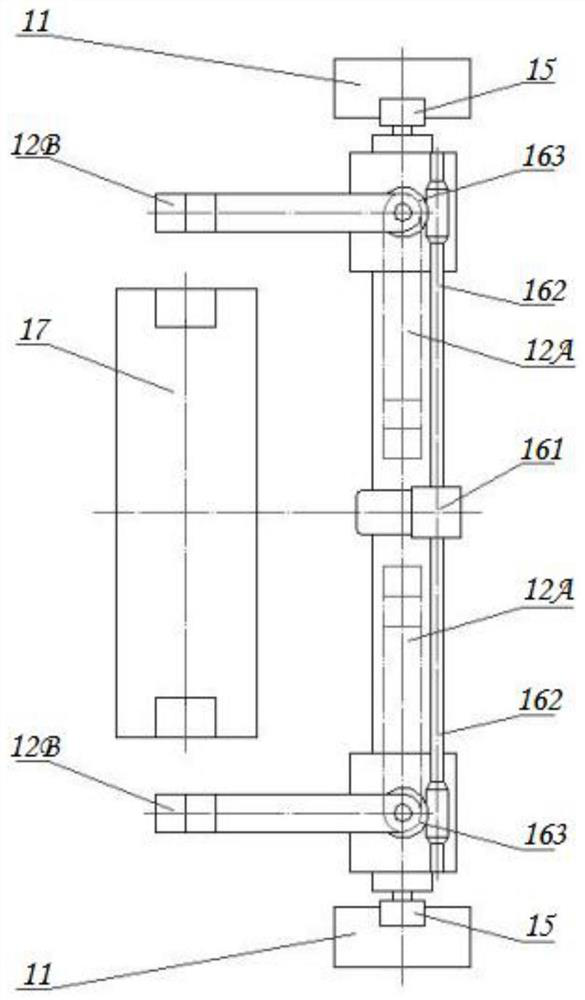

[0025] like Figure 1-Figure 3 , the embodiment of the present invention provides a lifting swing arm roll changing device, which includes a roll changing frame 11, two swing arms 12, a lifting drive mechanism 14 and a swing drive mechanism, and the swing arm 12 is equipped with a The bearing part of the roller shaft. The lifting drive mechanism 14 is used to adjust the vertical position of the swing arm 12 , and the swing drive mechanism is used to adjust the position of the swing arm 12 in the horizontal plane. Through the cooperation of the two, the spatial position of the swing arm 12 can be accurately positioned.

[0026] In one of the examples, as figure 1 and figure 2 , the two swing arms 12 and the swing driving mechanism are all arranged on the lifting platform 13, the lifting platform 13 is connected with the output end of the lifting driving mechanism 14, and the two swing arms 12 are connected with the swing driving mechanism respectively. The mechanism is conn...

Embodiment 2

[0039] An embodiment of the present invention provides a roll coating unit, including a roll coater, and the roll change area of the roll coater is arranged with the lifting swing arm roll change device provided in the first embodiment above.

Embodiment 3

[0041] An embodiment of the present invention provides a single-roller coating machine, which can be used as the roll coater in the second embodiment above.

[0042] like Figure 4-Figure 5 , the single-roll coating machine includes a coating machine frame 21, an upper coating roller 222 and a lower coating roller 232, and it further includes an upper roller frame 221, which is arranged on the top of the coating machine frame 21 and is used to drive the upper The upper lifting mechanism 223 of the roller frame 221 lifting, the lower roller frame 231 and the lower lifting mechanism 233 arranged at the bottom of the coating machine frame 21 and used to drive the lifting of the lower roller frame 231; the bearing seat of the upper coating roller 222 Slidingly arranged on the upper roller frame 221 and the sliding direction is parallel to the axial direction of the upper coating roller body 2221; the bearing seat of the lower coating roller 232 is slidingly arranged on the lower r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com