Optical fiber acoustic communication method and device

A technology of optical fiber and hot-melt device, which is applied in the field of optical fiber, can solve problems such as troublesome tool inventory, affect work efficiency, and difficulty in continuing processing, and achieve the effects of improving work efficiency, stable signal transmission, and improving the success rate of fusion splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

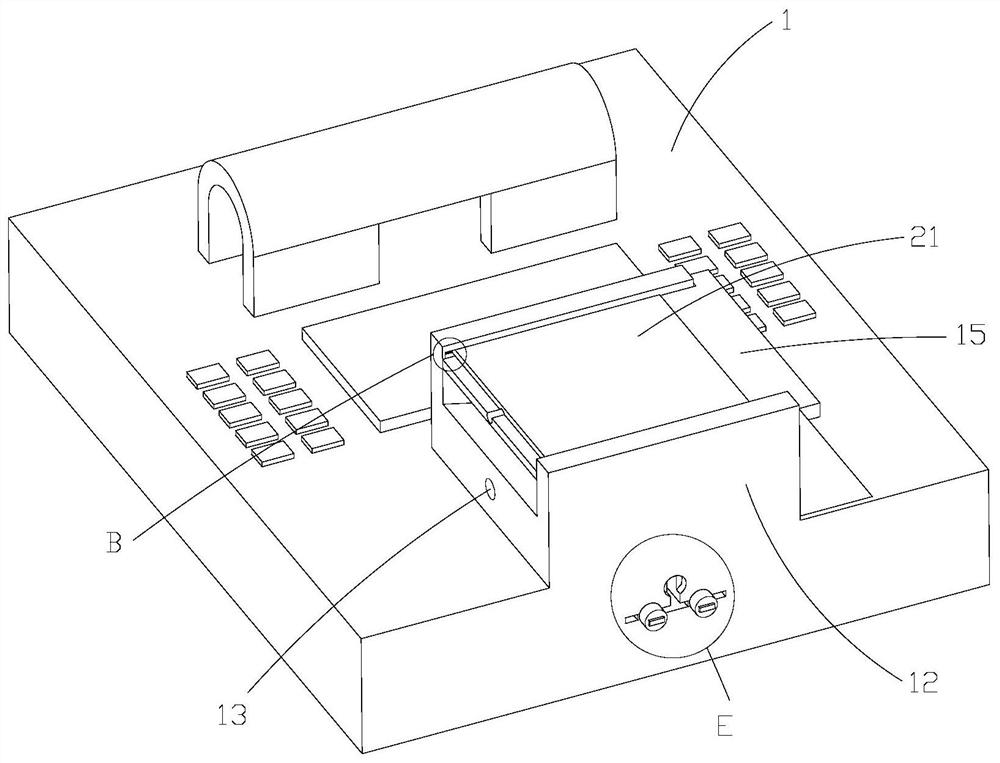

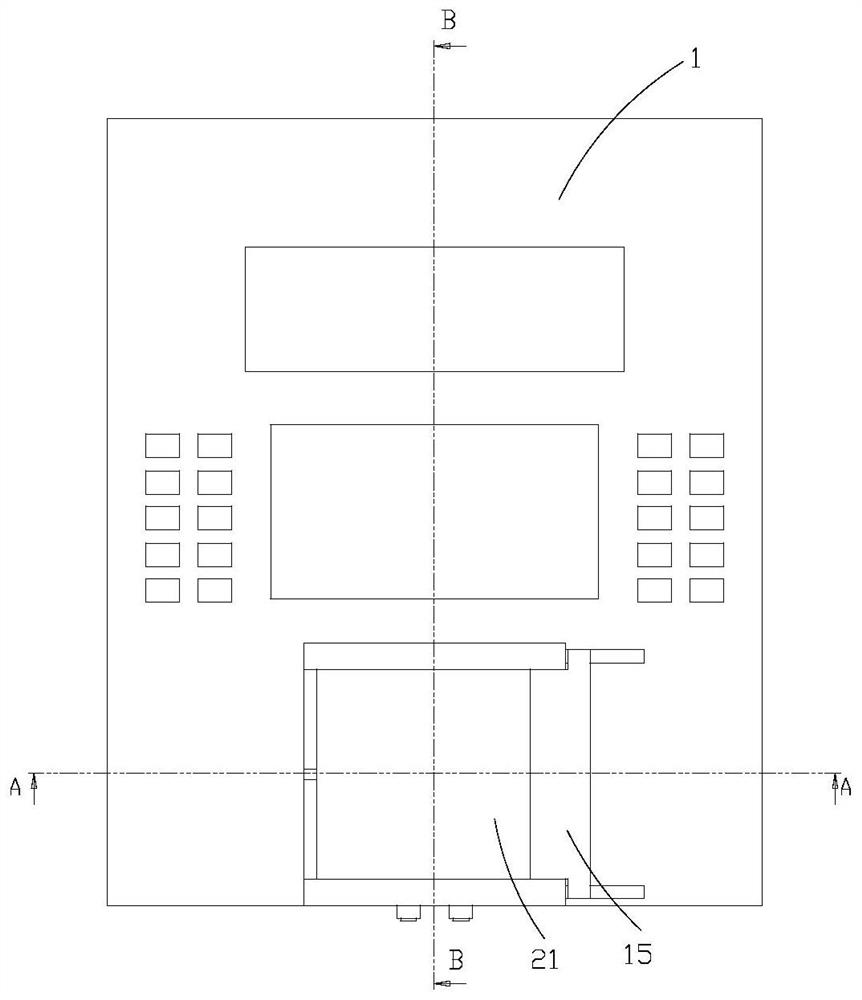

[0026] Such as Figure 1-12 As shown, a hot-melt device includes a hot-melt machine 1, a support frame 12, a first shear hole 13, a fixed rod 14, a rotating plate 15, a shear knife 2, a cutting part 3, a first empty slot 16, a drive Part 4, the second empty slot 17, a plurality of replacement parts 5; the support frame 12 is arranged on the hot-melt machine 1, the first shear hole 13 is arranged on the first support frame 12, and the fixing rod 14 is arranged on the On the support frame 12, the rotating plate 15 is rotatably arranged on the fixed rod 14, the shearing knife 2 is arranged on the support frame 12 so as to move up and down, and the cutting part 3 is arranged on the rotating plate 15. , the first empty slot 16 is arranged on the support frame 12, the driving part 4 is arranged on the first empty slot 16, the second empty slot 17 is arranged on the support frame 12, and a plurality of replacement parts 5 are arranged on the described On the second empty groove 17. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com