Lifting structure and lifting method used for tank transportation

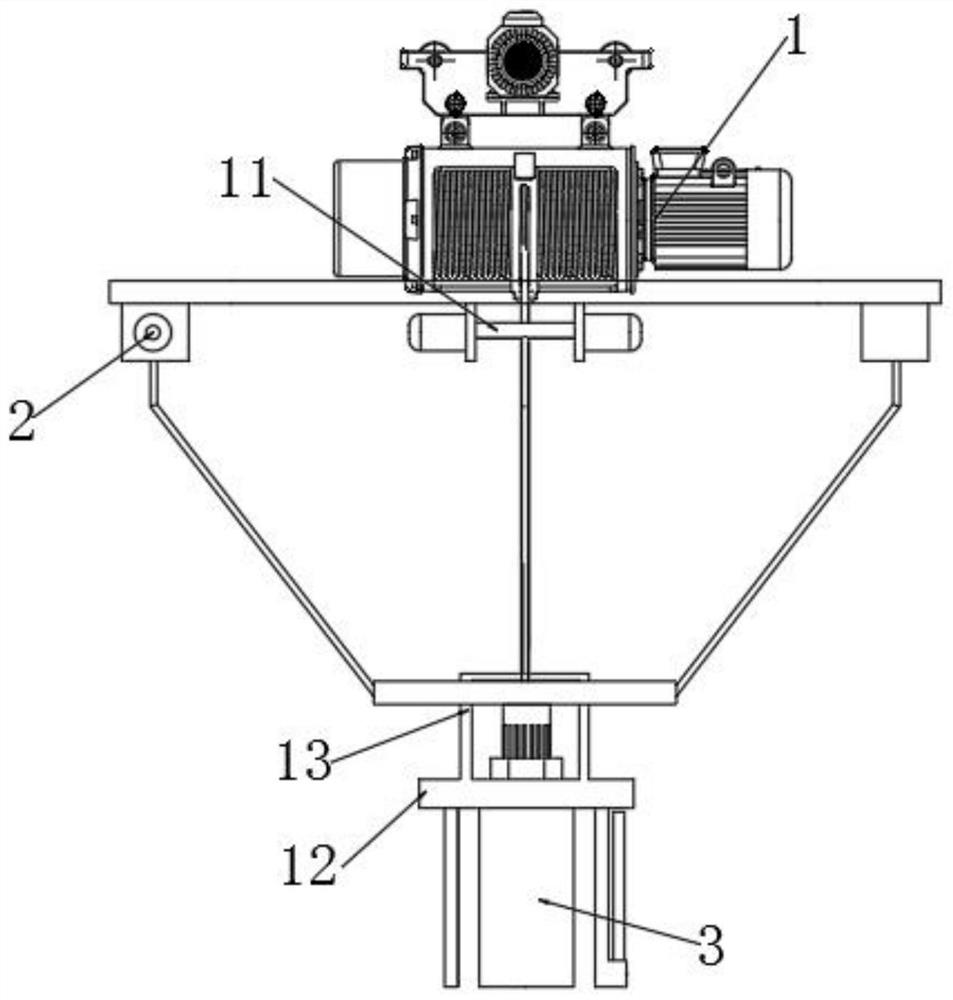

A technology of tank body and lifting seat, which is applied in the direction of transportation and packaging, clockwork mechanism, load hanging components, etc. It can solve the problems of connected steel cables shaking, hidden safety hazards, etc., and achieve the goal of ensuring vertical lifting and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

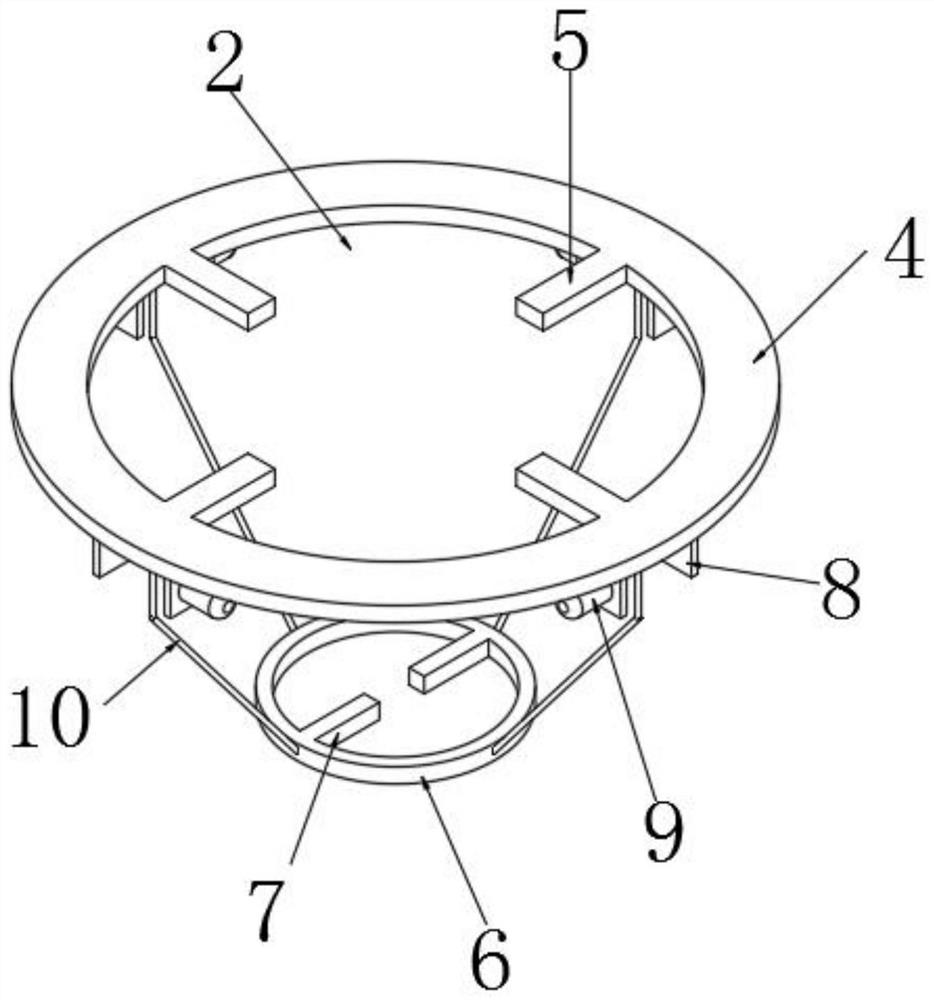

Examples

Embodiment approach

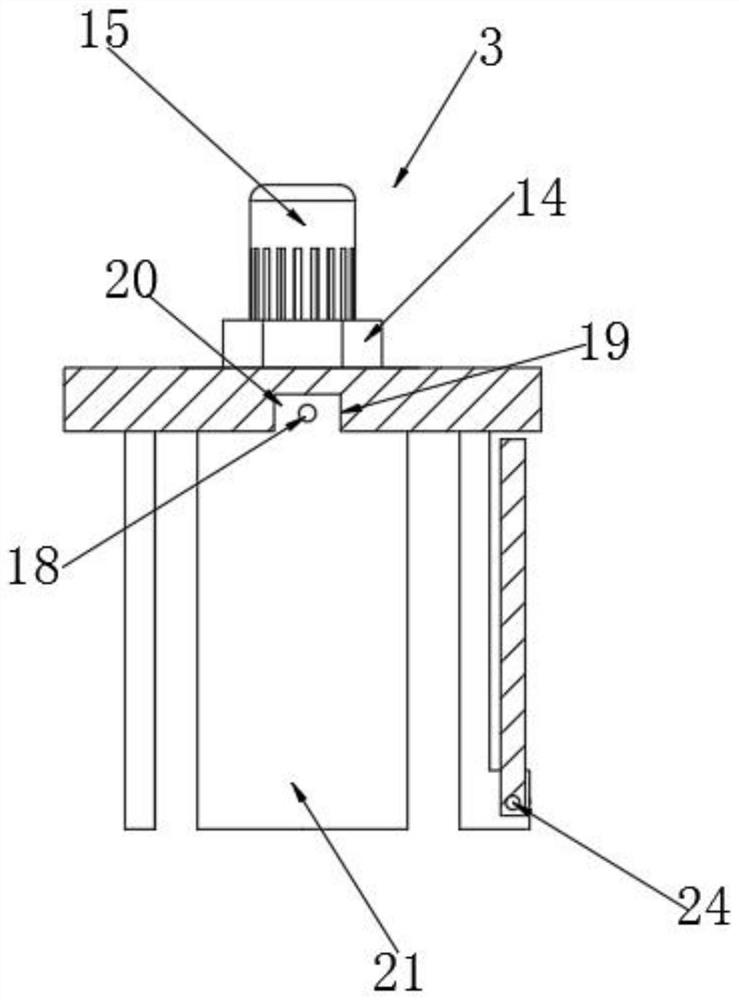

[0035] As an embodiment of the present invention, a third servo motor 23 is installed on the outside of the motor plate 22, a rotating shaft 24 is installed at the output end of the third servo motor 23, and the two ends of the rotating shaft 24 are installed with the motor plate 22 bearings, and the rotating plate 25 is installed on Outside the rotating shaft 24, the third servo motor 23 on the motor plate 22 drives the rotating shaft 24 to rotate, and then realizes the rotation of the rotating plate 25. At this time, the rotating plate 25 rotates from the vertical state to the horizontal state, which plays a protective role when the tank body is lifted and transported. Effect, clamping plate 21 inboards are equipped with non-slip rubber pads, which are convenient for clamping plate 21 and the tank body to be clamped tightly.

[0036] A lifting method for a lifting structure used for tank transportation, the specific operation steps of the lifting method are:

[0037]Step 1: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com