Battery trays and vehicles

A battery and pallet technology, which is applied to vehicle parts, battery pack parts, circuits, etc., can solve the problems of low structural strength of the battery pallet, strong anti-turbulence ability, and easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

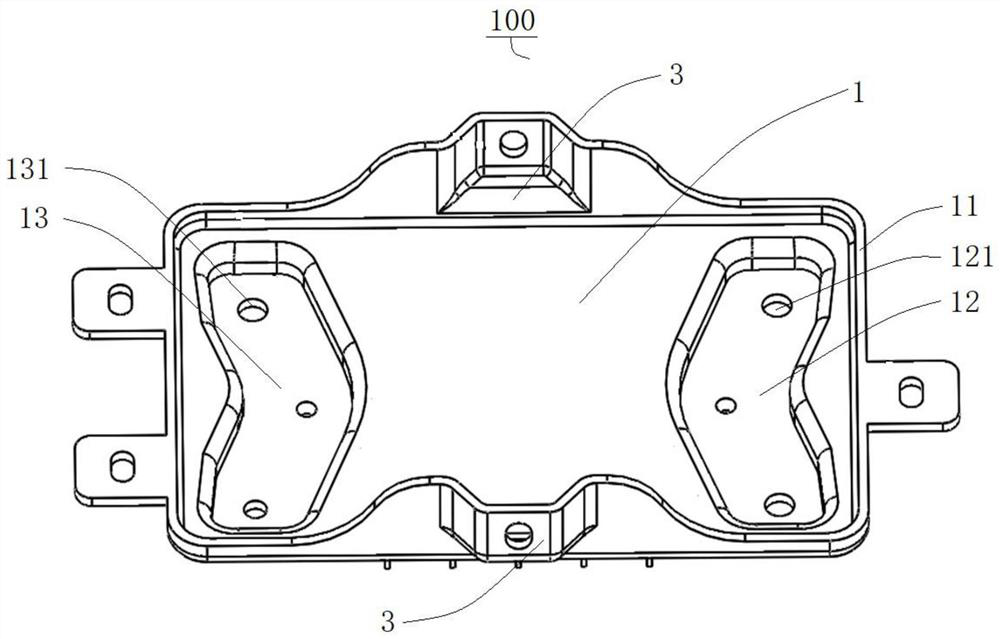

[0132] A storage battery tray 100 includes: a tray body 1 , a reinforcement part 2 and a pair of lifting lugs 3 .

[0133] Among them, such as figure 1 As shown, the periphery of the tray body 1 is provided with a limiting flange 11, and the two sides of the bottom of the tray body 1 are respectively provided with a first concave groove 12 and a second groove 13, and the first groove 12 and the second groove 13 is arranged symmetrically with the center line of the tray body 1, part of the groove walls of the first groove 12 and the second groove 13 are bent towards the side facing each other, and the sides of the first groove 12 and the second groove 13 The bottom surface is even. The first groove 12 is provided with two first installation holes 121 and a water leakage hole 14 , and the second groove 13 is provided with two second installation holes 131 and a water leakage hole 14 .

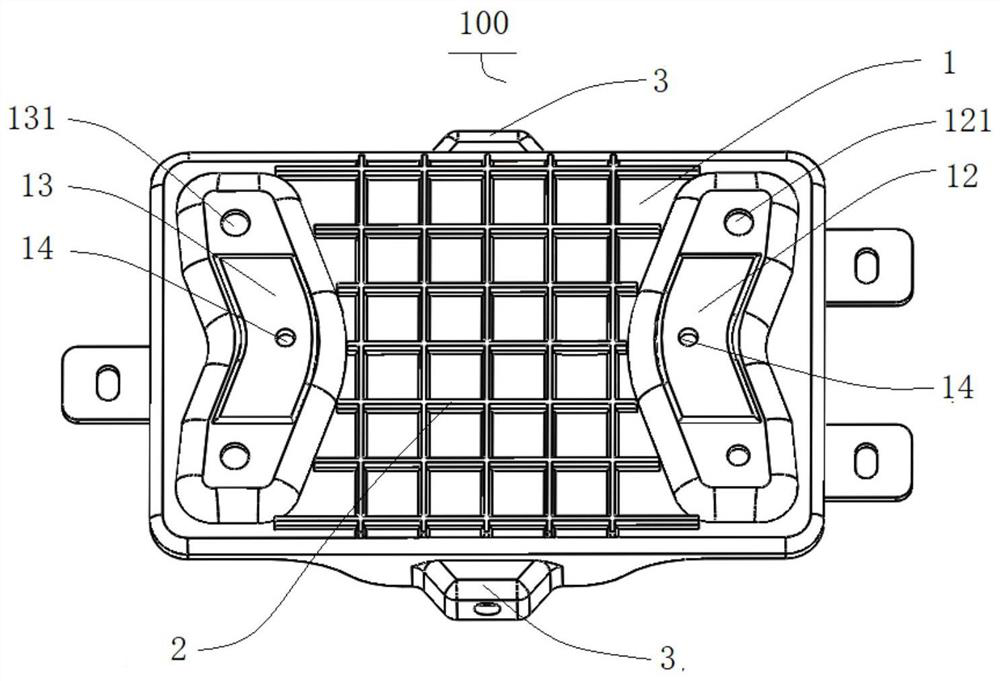

[0134] Such as figure 2 As shown, the reinforcement part 2 is provided at the bottom of th...

Embodiment 2

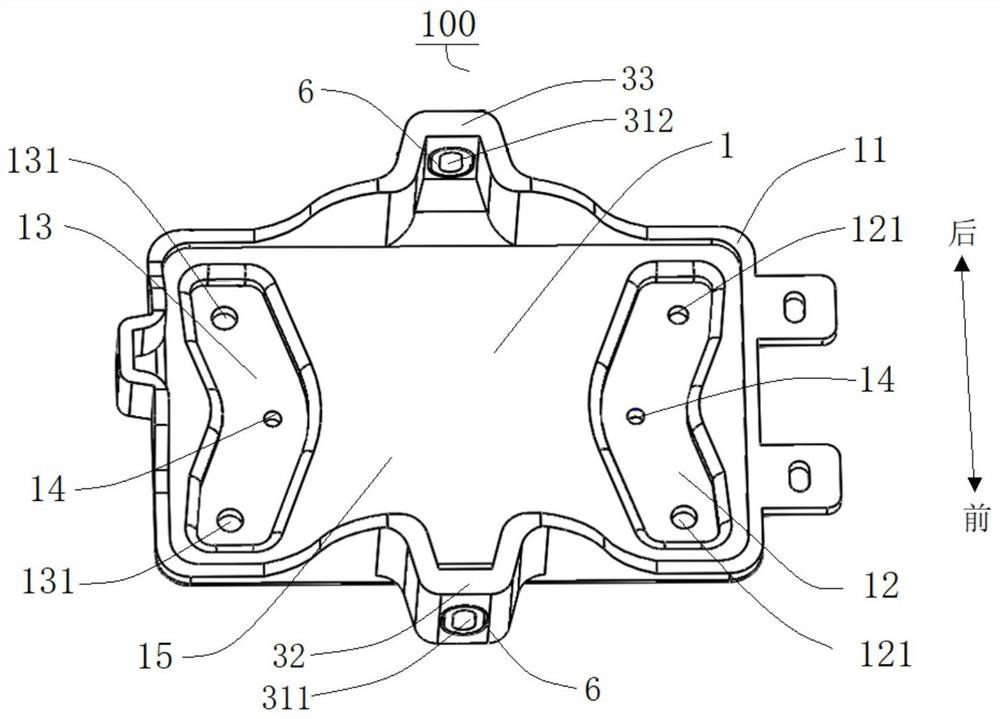

[0139] A storage battery tray 100, different from Embodiment 1, on the basis of Embodiment 1, such as image 3 As shown, the local thickness of the lifting lug 3 is increased, and a second gasket 6 is respectively embedded in a pair of hanging lugs 3 corresponding to the hanging holes 31 .

[0140] Such as Figure 4 As shown, the reinforcement part 2 is a plurality of reinforcement ribs 22 , the plurality of reinforcement ribs 22 are symmetrically arranged on the bottom of the tray body 1 , and the reinforcement ribs 22 extend to the bottom of the lifting lug 3 .

Embodiment 3

[0142] A storage battery tray 100 includes: a tray body 1 , a reinforcement part 2 and a pair of lifting lugs 3 .

[0143] Among them, such as Figure 5 As shown, the periphery of the tray body 1 is provided with a limiting flange 11, and the two sides of the bottom of the tray body 1 are respectively provided with a first concave groove 12 and a second groove 13, and the first groove 12 and the second groove 13 is arranged symmetrically with the center line of the tray body 1, part of the groove walls of the first groove 12 and the second groove 13 are bent towards the side facing each other, and the sides of the first groove 12 and the second groove 13 The bottom surface is even, the first groove 12 is provided with two first mounting holes 121 and a leaking hole 14, the second groove 13 is provided with two second mounting holes 131 and a leaking hole 14, the two first A first gasket 5 is bonded to the installation hole 121 and the two second installation holes 131 .

[014...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com