High-precision differential linear displacement sensor

A linear displacement sensor, differential technology, applied in the field of displacement sensor, can solve the problems of missing shell, falling, collision damage, etc., to achieve the effect of easy replacement and maintenance, avoid precision drop, and increase sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

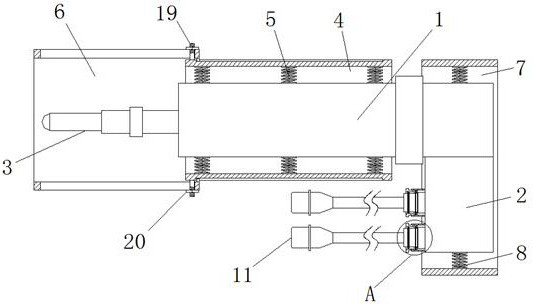

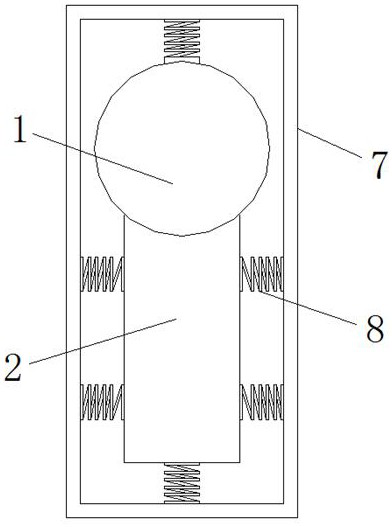

[0025] Example 1 as Figure 1-3 As shown, this high-precision differential linear displacement sensor includes a sensor body 1, the sensor body 1 includes a junction box 2 and a measuring rod 3, the outer side of the sensor body 1 is provided with a main protective sleeve 4, and the main protective sleeve 4 The interior of the sensor is fixed with multiple sets of evenly distributed first springs 5, and the end of the same group of first springs 5 away from the main protective cover 4 is fixedly connected to the side wall of the sensor body 1, and the outer left end of the main protective cover 4 is provided with Secondary protective cover 6, the upper and lower sides of the inner side wall of the secondary protective cover 6 are fixedly connected with slide blocks on the right side, and the upper and lower ends of the outer side wall of the main protective cover 4 are provided with chutes matched with the slide block. 4. There are two locking mechanisms connected to the sec...

Embodiment 2

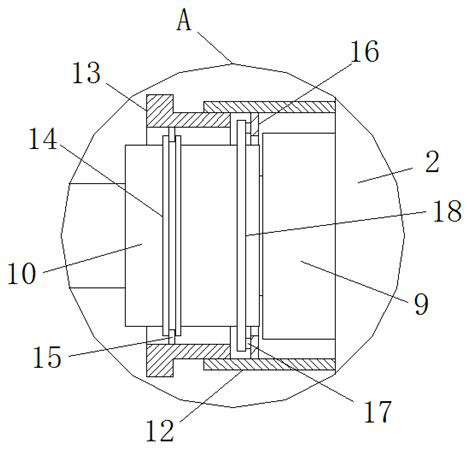

[0026] Embodiment 2 is on the basis of embodiment 1 such as figure 2 As shown, a group of connection sockets 9 are fixedly connected to the left side wall of its junction box 2, and a group of connection sockets 9 are electrically connected with the output end of the sensor body 1, and each connection socket 9 output ends are electrically plugged with a Adapter 10, each adapter 10 is electrically connected with a connector 11 by a wire, each adapter 10 is connected with an anti-off mechanism and is connected with the junction box 2 through an anti-off mechanism, and the adapter 10 is connected to the junction box 9 from the junction socket 9 The separation of the connector 11 from the sensor body 1 can be completed by pulling it out. When the differential linear displacement sensor or the external wire and the connector 11 are damaged, it can be easily replaced and repaired quickly.

Embodiment 3

[0027] Embodiment 3 is such as on the basis of embodiment 2 figure 2 As shown, each of its anti-off mechanisms includes an internal thread sleeve 12, a T-shaped threaded sleeve 13 and a fixed ring 14. The internal thread sleeve 12 is located on the outside of the wiring socket 9, and the right end of the internal thread sleeve 12 is connected to the junction box. 2 is fixedly connected to the left side wall, the inner side wall of the fixed ring 14 is fixedly connected to the left end of the side wall of the same side adapter 10, and the left end of the inner side wall of the T-shaped threaded sleeve 13 is fixedly connected with slide bars 15 on both sides, and the fixed ring The outer ring wall of 14 is provided with the annular chute that matches with slide bar 15, and the right end of T-shaped threaded sleeve 13 outer wall is threadedly connected with the left end of the inner side wall of internal threaded sleeve 12, and twists T-shaped threaded sleeve 13 and makes it with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com