One-way rotary clamping mechanism

A clamping mechanism and one-way rotation technology, applied in the field of leaf spring assembly, can solve the problems of low automation, difficulty in meeting the production requirements of enterprises, high labor intensity, etc., and achieve the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

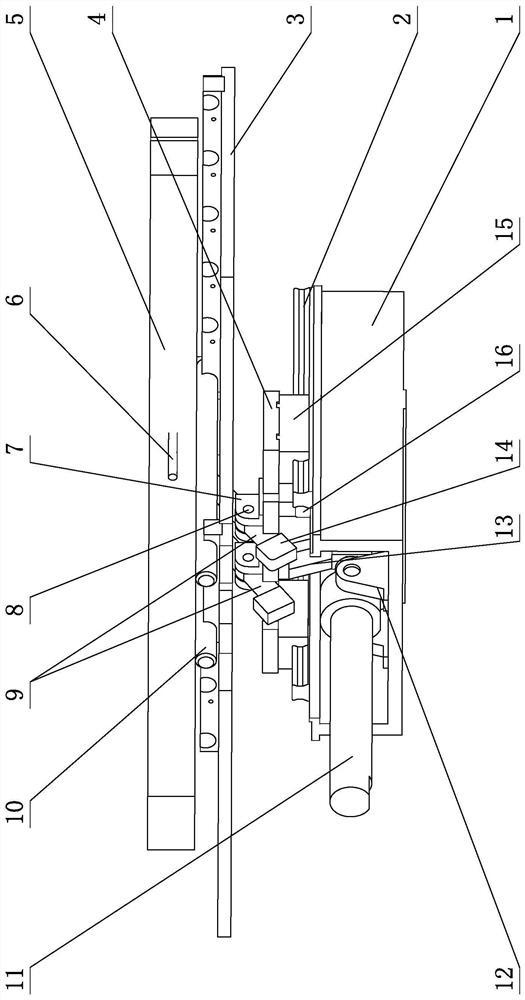

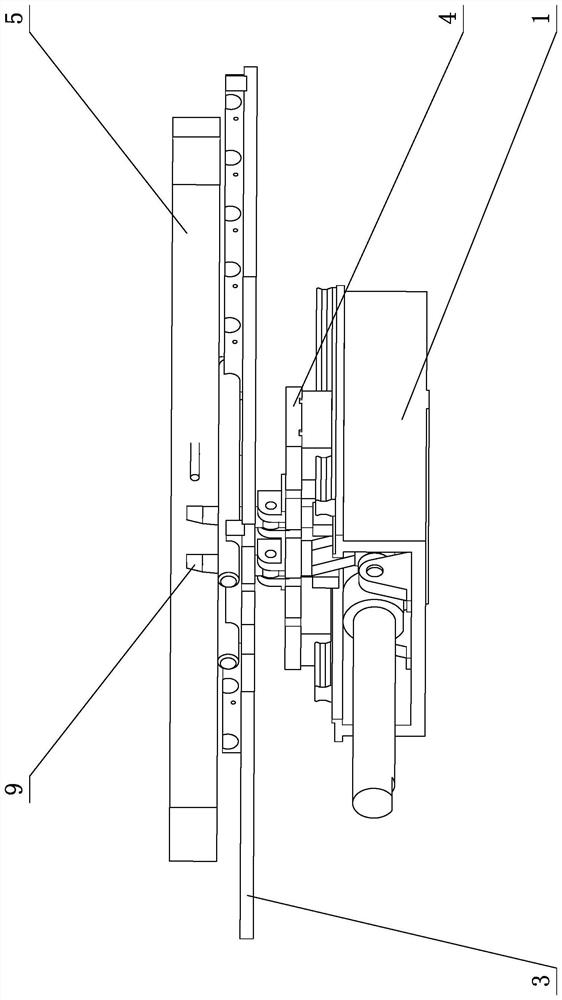

[0021] The present invention will be further described below in conjunction with the accompanying drawings:

[0022] like Figure 1-Figure 3 , The one-way rotation clamping mechanism of the present invention includes a clamping table 3 and a support frame 1 arranged below the clamping table 3. The clamping table 3 is provided with a long hole 18, and the long hole 18 The upper surface of the clamping table 3 at one end is provided with a backing seat 17; a movable seat 4 is arranged between the clamping table 3 and the support frame 1, the movable seat 4 is connected with the support frame 1 through a sliding unit, and the movable seat 4 is composed of The drive unit is driven; the moving base 4 is connected with the swing clamping block 9 through the rotating pin 8, and the swing clamping block 9 is eccentrically installed; the upper part of the swing clamping block 9 penetrates the elongated hole 18, and the lower part of the swing clamping block 9 is close to the backer sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com