Method for analyzing front axle holding capacity of air suspension

An air suspension and analysis method technology, applied in the field of vehicle suspension, can solve problems such as cumbersome process, inability to lift the front axle, and low customer satisfaction, and achieve high customer satisfaction and avoid the effect of inability to lift the front axle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Taking a full-air suspension truck as an example, there is no failure under normal full-load conditions, but the front axle cannot be lifted during the unloading process. The method for analyzing the holding capacity of the air suspension front axle of the present invention is used for analysis, so as to find out the fundamental reason why the front axle cannot be lifted.

[0051] The first step is to collect the background information of the full air suspension truck, including air springs, pressure valves, load conditions, fault location and fault frequency;

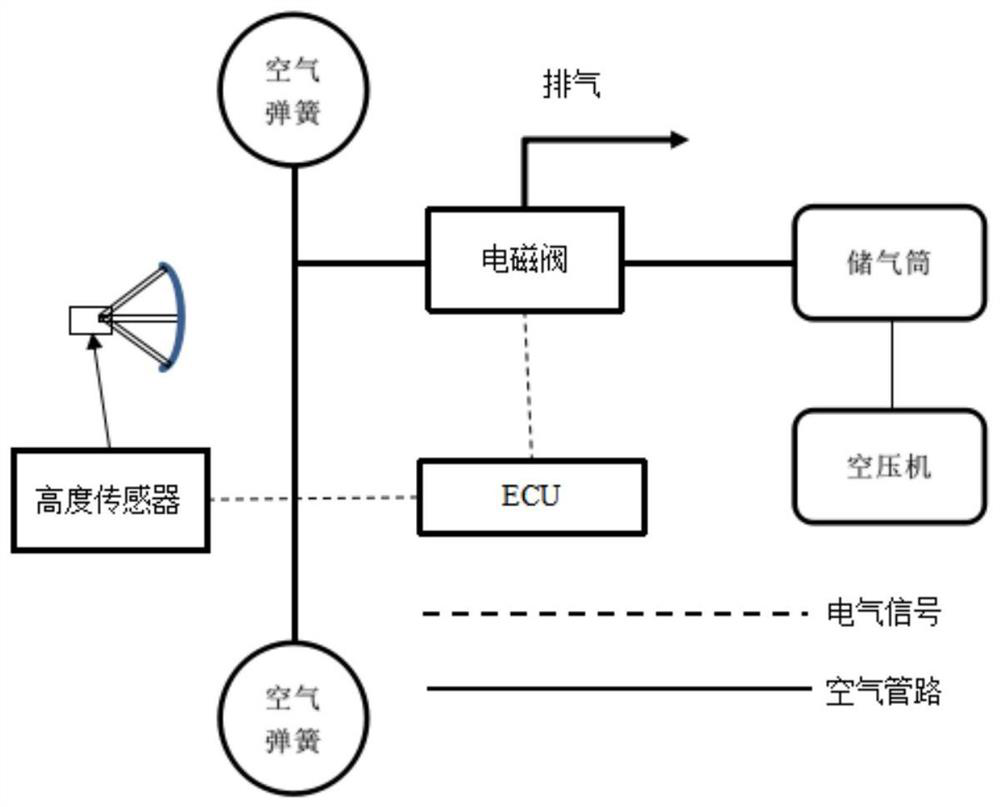

[0052] The second step, such as figure 1 As shown, draw a logical block diagram of the system function according to the model;

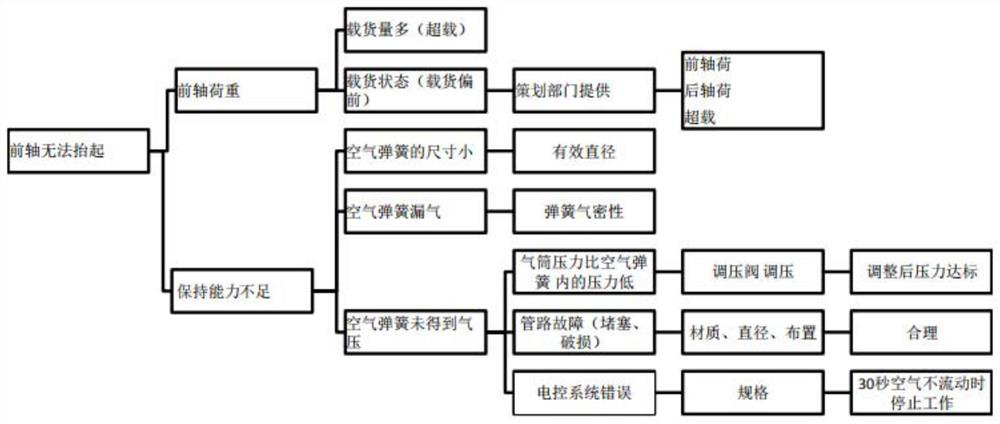

[0053] The third step, such as figure 2 As shown, build a fault tree analysis FIA according to the problem phenomenon;

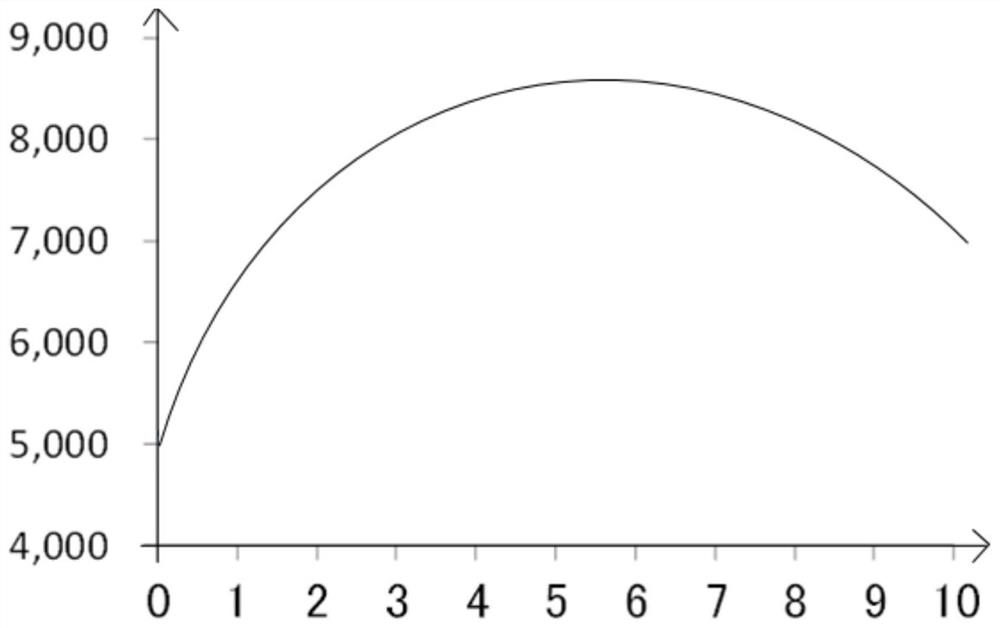

[0054] The fourth step, such as Figure 4 to Figure 5 As shown, collect relevant vehicle parameters from the planning department, including the total vehicle we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com