Steel bar machining protective shed convenient to disassemble and assemble

A technology for steel bar processing and protective sheds, applied in industrial buildings, buildings, building structures, etc., can solve the problems of different sizes of protective sheds, troublesome assembling of protective sheds, waste of wood, etc., to optimize appearance, save materials, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

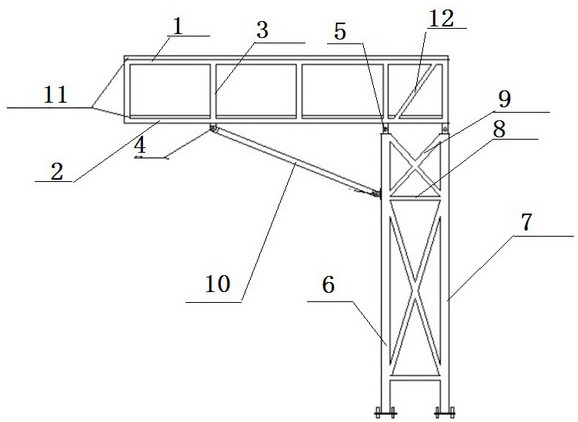

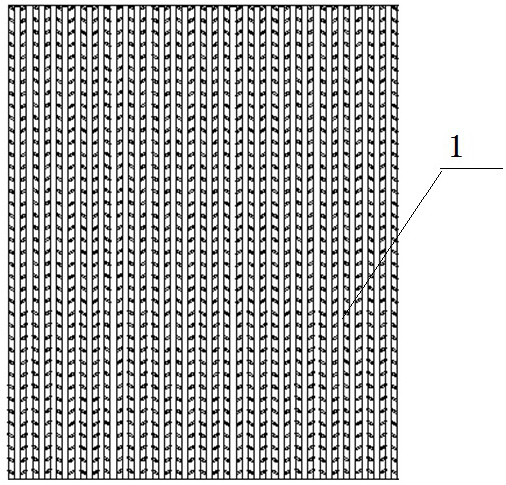

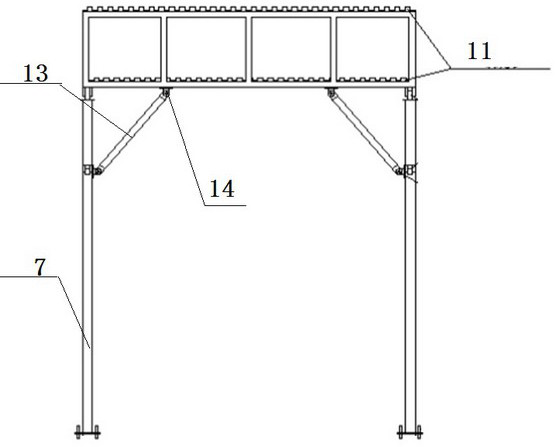

[0014] A steel bar processing protective shed that is easy to disassemble, such as figure 1 , figure 2 , image 3 As shown, the upper frame 1 and the lower frame 2 are made of steel, and the upper and lower frames 1 and 2 are fixedly connected by the vertical rods 3 evenly distributed along their four sides to form an upper scaffolding. A symmetrical front pin seat 4 and two symmetrical side pin seats 5 are respectively arranged on the bottom surface, two symmetrical rear pin seats 14 are respectively arranged on the bottom surface of the rear frame of the lower frame, and front and rear columns 6, 7 are combined and fixed together by cross brace 8 and scissors brace 9 to form a composite column. The bottom plates set at the lower ends of the front and rear columns 6 and 7 are fixed to the ground foundation through bolts, and the connecting lugs set at the upper ends are fixed through pin shafts. Connected with the side pin seat 5 of the upper scaffold, the first diagonal s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com