Transmission type rapid humidifying and candy-producing furnace end

A technology of transmission type and burner head, which is applied in confectionery, confectionery industry, and thermometers using electric/magnetic elements that are directly sensitive to heat, etc. Lowering and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

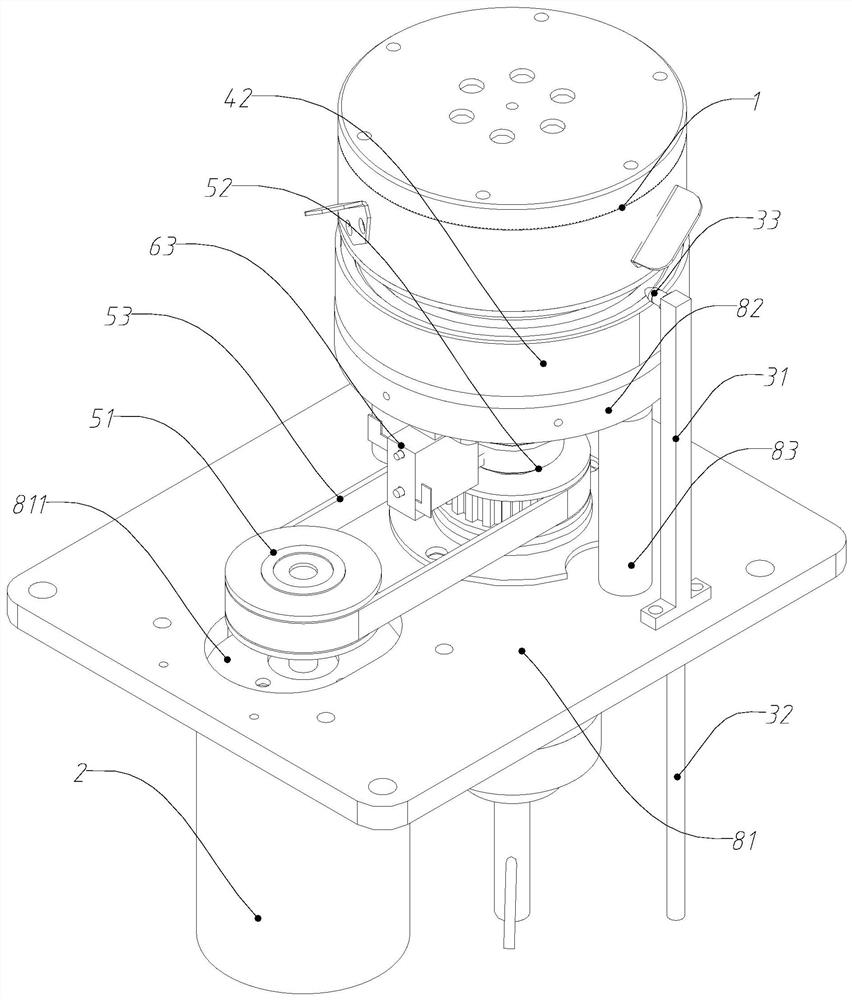

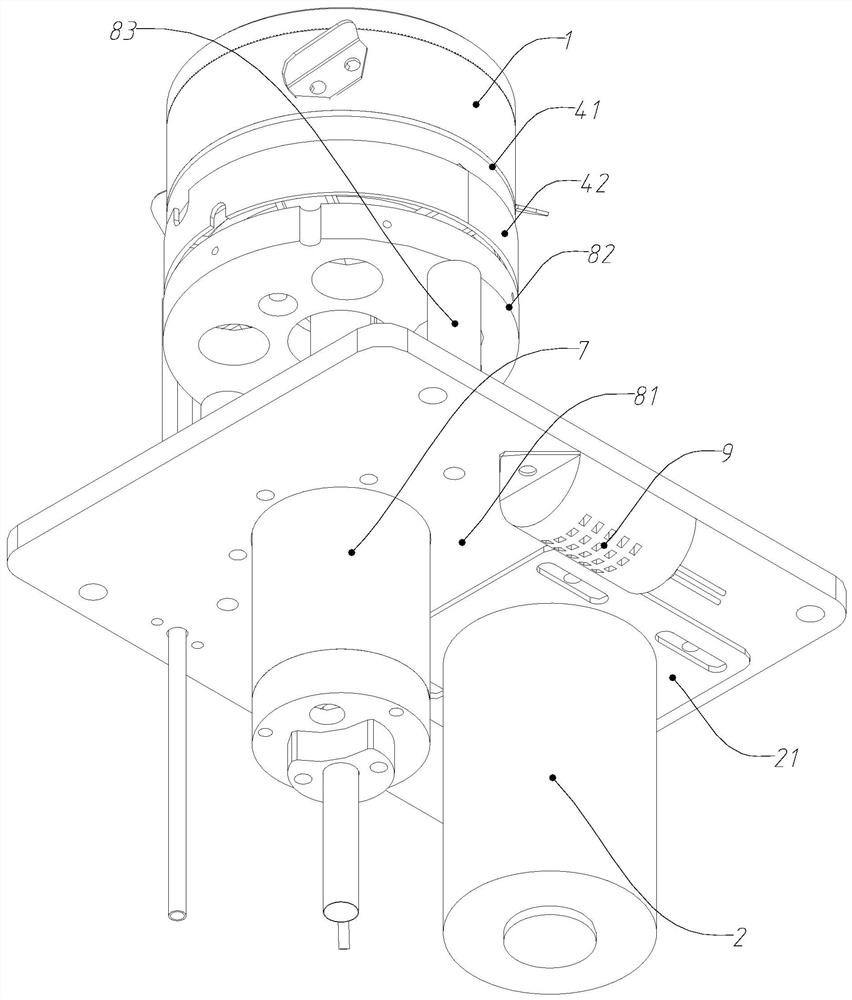

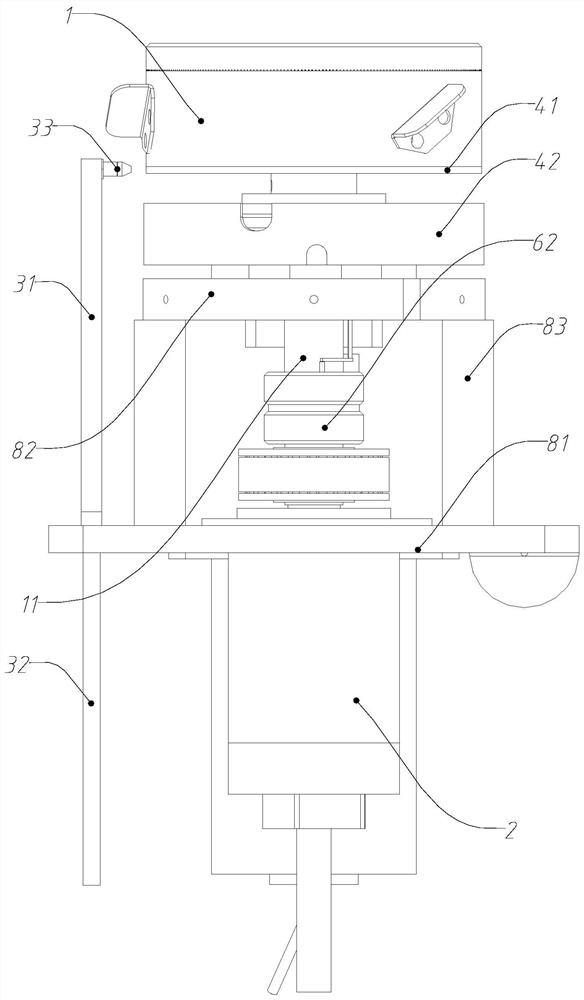

[0051] As a further technical solution of the embodiment, such as Figure 7 As shown, in order to further improve the efficiency of increasing the air humidity near the body 1 of the sugar-making stove, several humidifying devices are evenly arranged on the outside of the body 1 of the sugar-making stove. On the base; some water spray heads 33 are all facing the side wall of the sugar-making stove head body 1.

[0052]Specifically, the water sprayers 31 of the humidifying device are all bolted to the fixing plate 81, and several water spray heads 33 are all directed toward the side wall of the sugar-making stove head body 1 close to the side of the heating plate 41, thereby ensuring the spraying effect of the water spray heads 33. The fine water column can quickly obtain enough heat from the body 1 of the sugar-making stove head, and a number of humidifying devices are evenly arranged near the outside of the sugar-making stove body 1, not only by evaporating the water column i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com